A cable-free motion driving method for a permanent magnet microrobot in a coil system

A micro-robot and motion-driven technology, applied in the field of mechanical science, can solve problems such as difficult to meet the needs of miniaturization, difficult to achieve working effects, and failure to deploy normally, achieving excellent control effects, excellent magnetic field characteristics, and solving functional limitations problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The cable-free motion driving method of the permanent magnet thin-film microrobot in the coil space system based on the MEMS micromachining technology provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

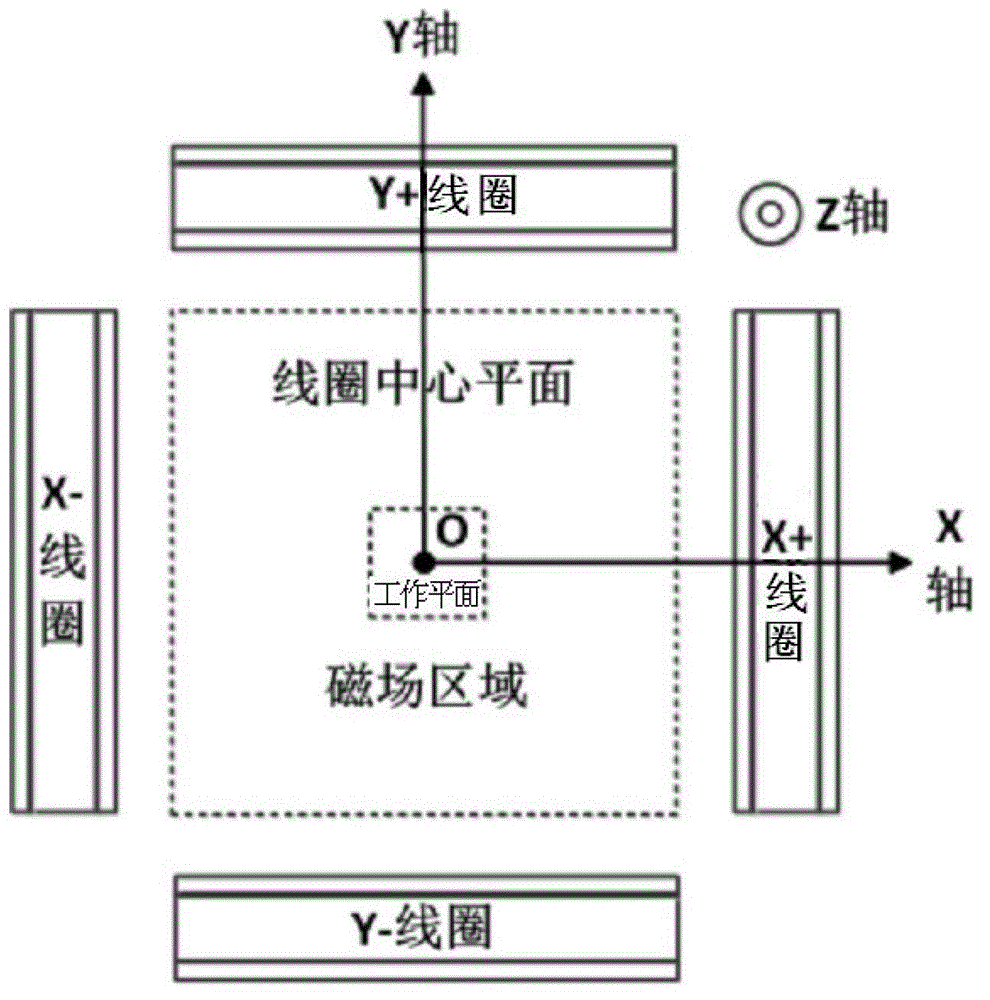

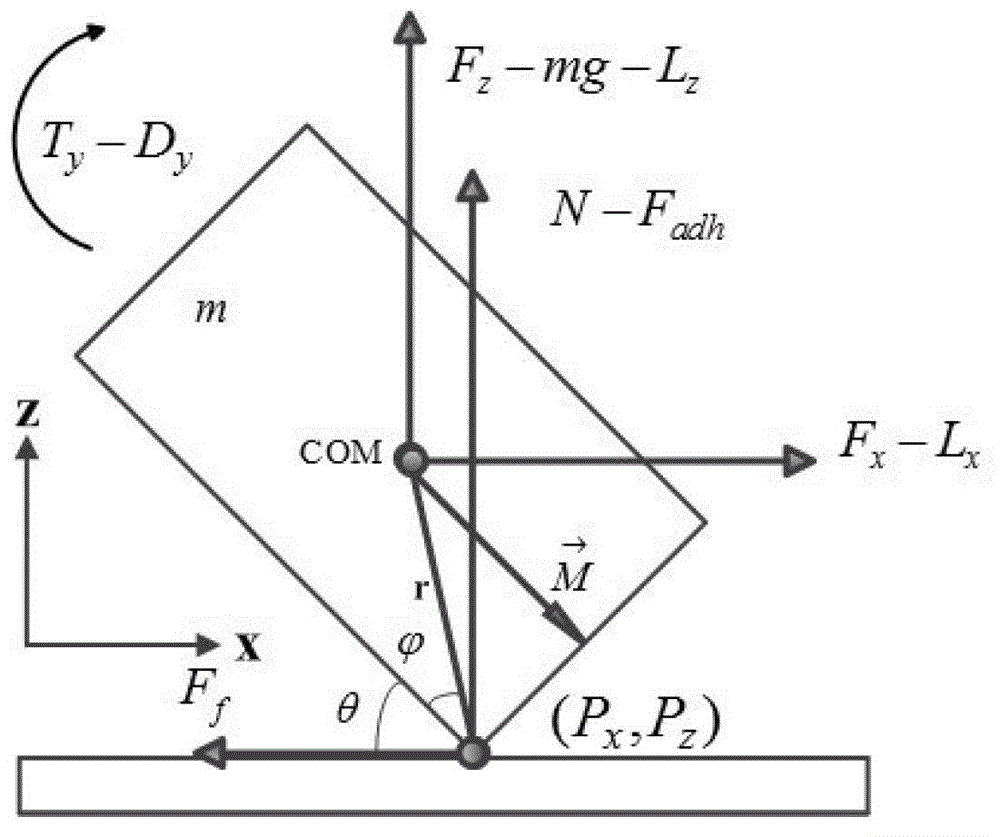

[0030] The method provided by the present invention realizes the processing of the permanent magnet micro-robot body through the MEMS patterned photolithography method, builds a specific coil system improved by Helmholtz coil deformation, and realizes the two-dimensional vibration and translation mode on this basis. plane movement.

[0031] The permanent magnet microrobot of the present invention is a film structure made of NdFeB permanent magnet material, and its specific processing and preparation process is as follows:

[0032] 1. Using NdFeB (chemical formula: NdFeB) permanent magnet powder and binder to prepare bonded magnet microstructure at room temperature. The permanent magnet material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com