Making method of micro-electro-mechanical V-type micro valve

A technology of microelectronic machinery and manufacturing methods, which is applied in the field of actuators, can solve problems such as high processing accuracy requirements, difficult processes, and complex structures, and achieve the effects of reducing processing accuracy requirements, simple manufacturing processes, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

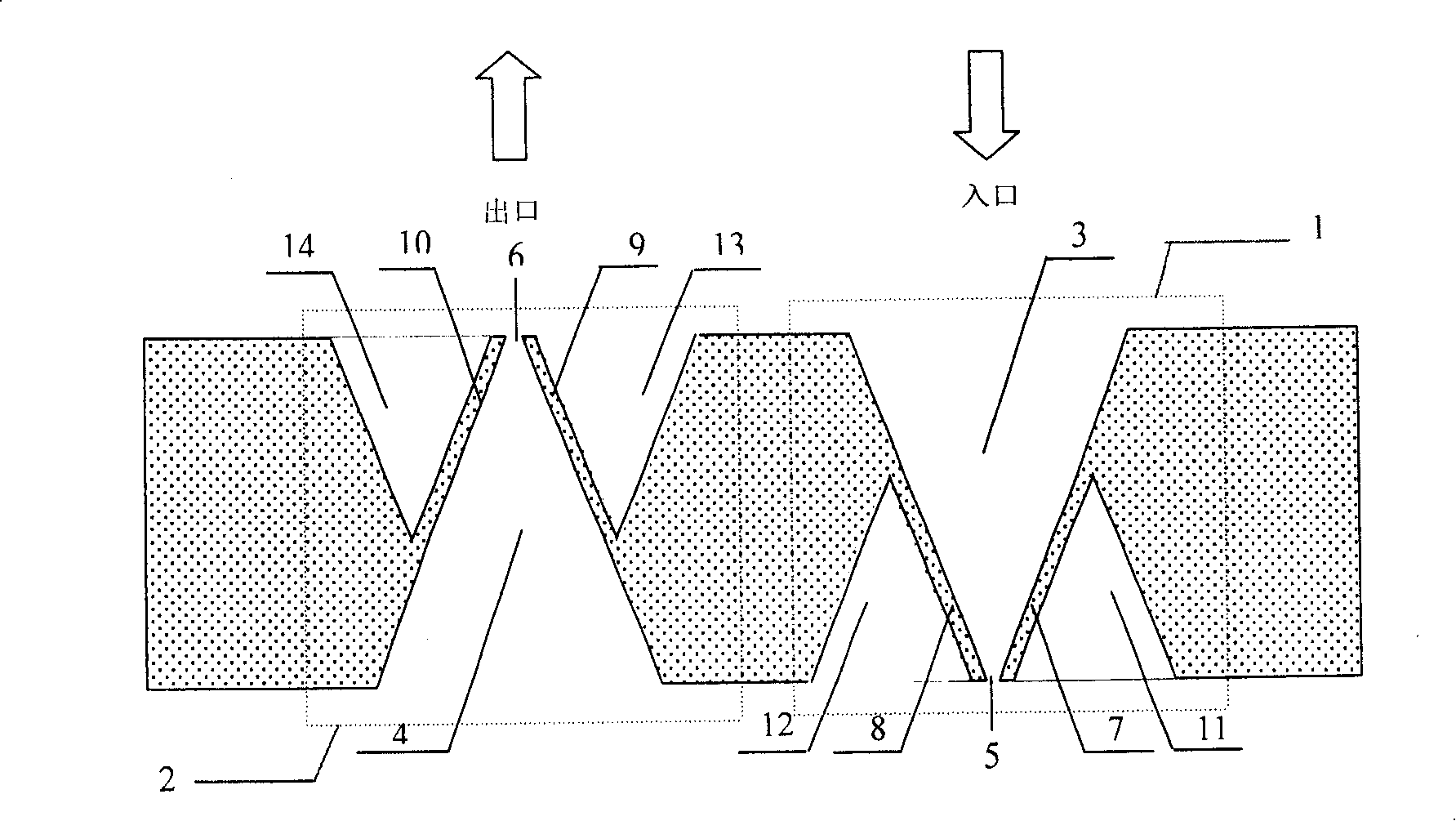

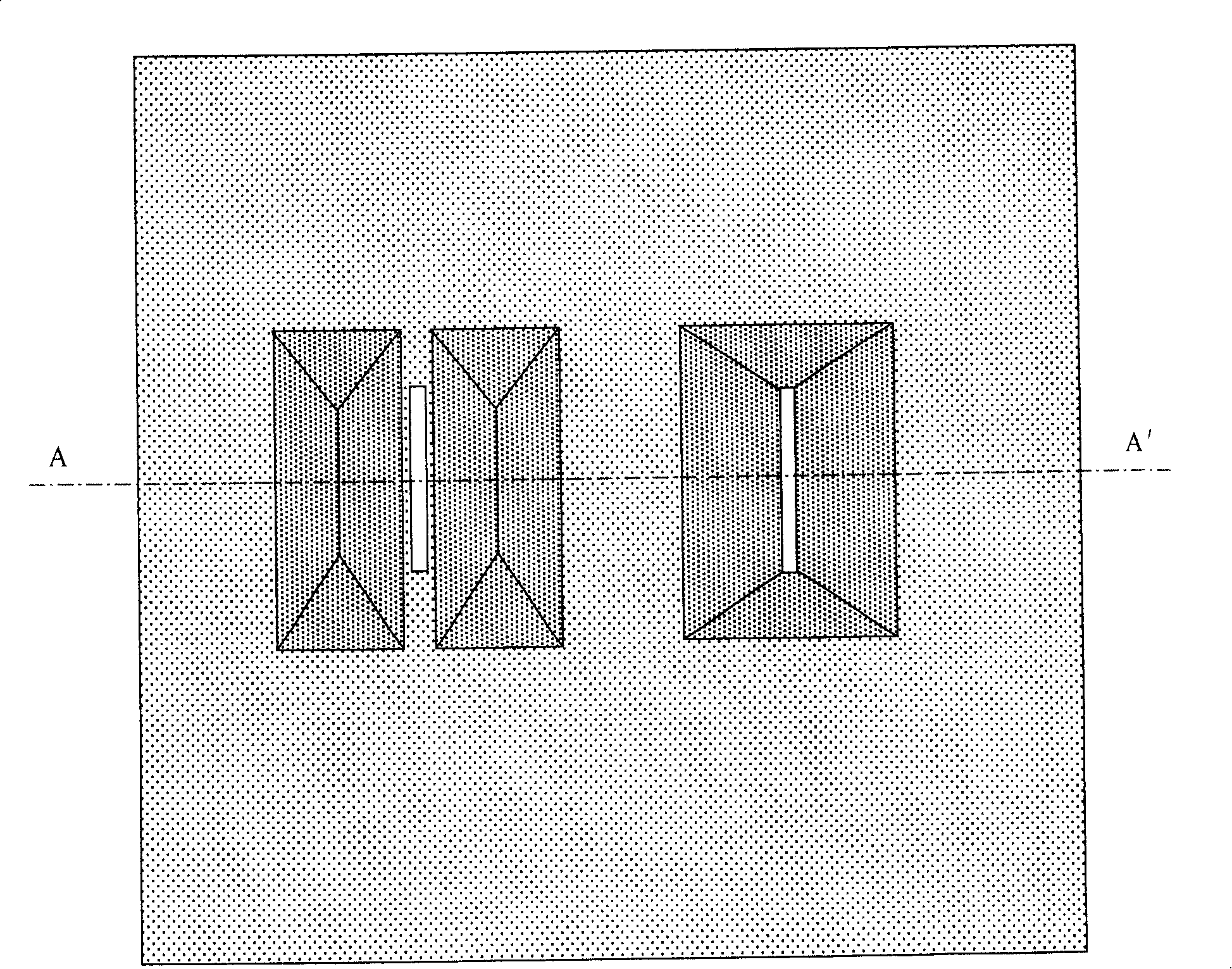

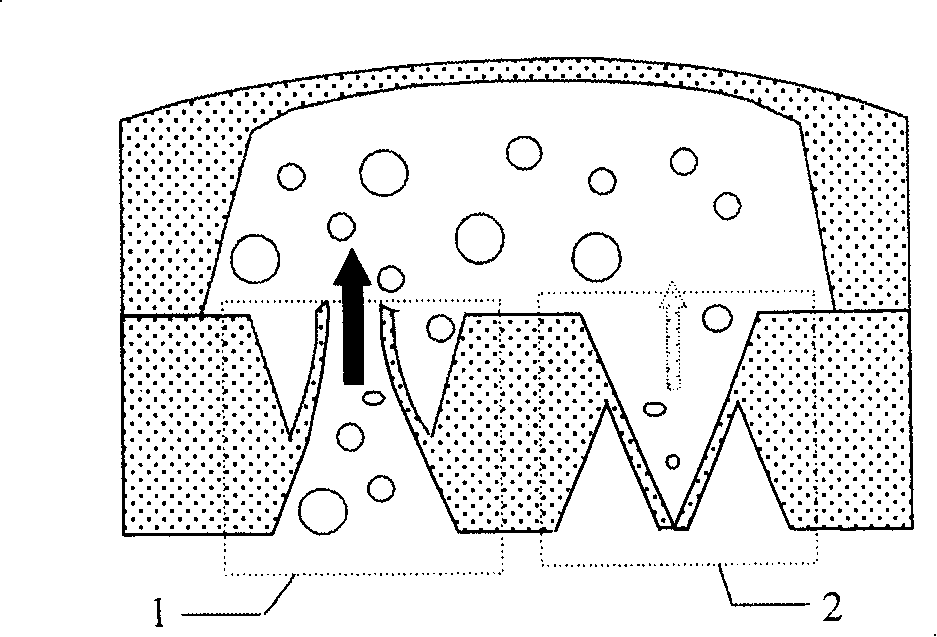

[0023] Micro-electromechanical V-type microvalve, which consists of: positive one-way valve [1] and reverse one-way valve [2] placed symmetrically and oppositely to the structure of the positive one-way valve, the positive one-way valve [2] The entire structure of the valve and the reverse one-way valve are formed on the silicon substrate, and the positive one-way valve [1] includes the water inlet [3], the water inlet seam [5], the valve plate [7] / [8] and two V type groove [11] / [12]; anti-check valve [2] includes water outlet [4], water outlet seam [6], valve plate [9] / [10] and two V-shaped grooves [13] / [ 14] (see attached figure 1 ).

[0024] For the above-mentioned V-shaped microvalve of micro-electronic machinery, the angle between the release valve plates on both sides and the angle of the V-shaped groove is the included angle of the anisotropic etching of crystal to silicon, and the optimal angle is 54°44′20 ", the thickness of the valve plate is half of the value obta...

Embodiment 2

[0031] The manufacturing method of the V-type microvalve of the microelectronic machinery described in embodiment 1, selects the double-sided polishing P-type (100) silicon chip thickness to be 330 μ m~550 μ m, double-sided oxidation 400nm, low-temperature plasma chemical vapor deposition, double-sided growth Si 3 N 4 200nm, double-sided photolithography window, etched with KOH aqueous solution for 1-2 hours, cooled at 40°C for over-etching until breakthrough, the etching time depends on the time required to engrave the thickness of the silicon substrate material, the etching height is the thickness of the silicon wafer, Go to Si after piercing 3 N 4 Protective layer, and finally use HF solution to remove the oxide layer.

[0032]The manufacturing method of the V-shaped microvalve of the above-mentioned microelectronic machinery, the water inlet seam, the water outlet seam, and the valve plate are all made of silicon micromachining, and are prepared after being corroded by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com