Strontium ruthenate material, and preparation method and application thereof

A technology of strontium ruthenate and raw materials, applied in the field of strontium ruthenate materials and preparation thereof, can solve the problems of lack of large-scale synthesis and production methods, limited reference information, etc., and achieves improved yield, reduced particle defects, and high density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

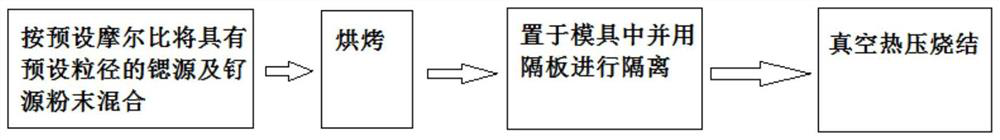

[0036] This application proposes a method for preparing strontium ruthenate material, which mainly includes the following steps: vacuum hot-press sintering is carried out on the raw materials for the preparation of strontium ruthenate material, and the vacuum hot-press sintering conditions include: vacuum degree≤10 -3 Pa, the hot-pressing temperature is 600-850°C, the hot-pressing pressure is 58.5-100MPa, and the hot-pressing time is 3-3.5h.

[0037] The above preparation raw materials can be obtained through the following steps: baking the mixed raw materials obtained by mixing the ruthenium source and the strontium source at 120-180° C. for 2-3 hours.

[0038] Among them, the source of strontium is SrO, the source of ruthenium is RuO 2 , the strontium source and the ruthenium source are mixed in a molar ratio of 0.9-1.1:0.9-1.1, and the optimal molar ratio is 1:1. When the mixing molar ratio of the strontium source and the ruthenium source is not 1:1, preferably the rutheni...

Embodiment 1

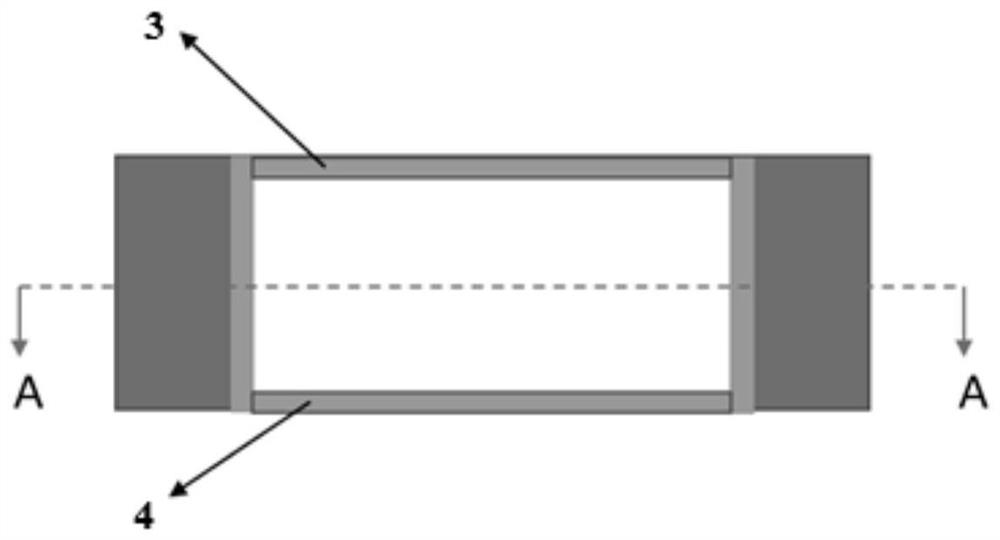

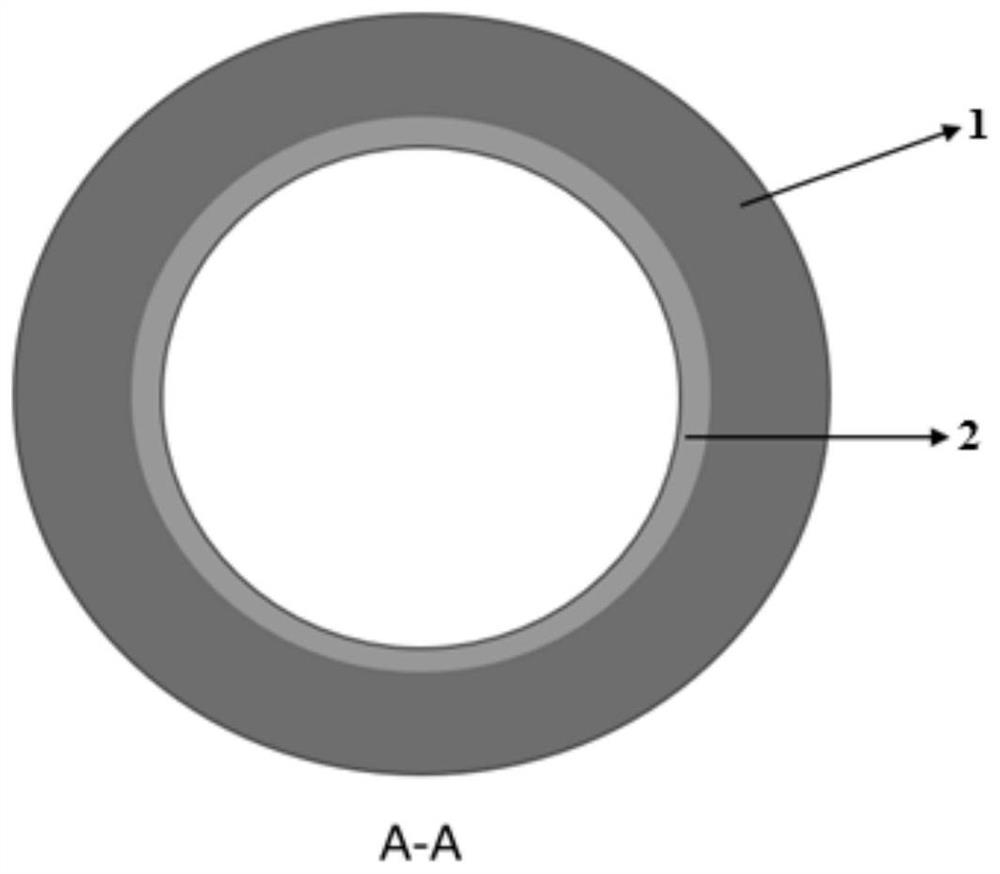

[0076] This embodiment provides a method for preparing a strontium ruthenate target, the main process of which is as follows figure 1 As shown, it is specifically divided into preparation of ruthenium source and strontium source, pulverization by crushing, powder mixing, baking, vacuum hot pressing sintering and mechanical processing.

[0077] details as follows:

[0078] With SrO and RuO 2 As strontium source and ruthenium source respectively, they are crushed into 100-400 mesh powder in a container filled with argon gas at room temperature. SrO powder and RuO 2 The powder is placed in an argon-filled container at a molar ratio of 1:1 for stirring and mixing. The mixing process is carried out by placing the above-mentioned mixing container in a temperature-controlled furnace and mixing at 150°C for 2.5 hours. After mixing, let it cool down to room temperature naturally, and pack it in vacuum plastic for later use.

[0079]Subsequently, the above-mentioned mixed powder aft...

Embodiment 2

[0087] This embodiment provides a method for preparing a strontium ruthenate target, the difference from Embodiment 1 is mainly as follows (other conditions are the same):

[0088] Will install SrO and RuO 2 The mold of the mixed powder is placed in the cavity of the vacuum hot press, and then vacuumed to a vacuum degree of about 8.0×10 -4 Pa. The cavity is heated to 850° C., and a pressure of 90 MPa on the longitudinal axis is applied to both ends of the mold in the cavity, and the temperature is maintained for 180 minutes.

[0089] With the test method of embodiment 1, the SrRuO provided by the present embodiment 3 The cross-sectional microstructure of the target sample is dense and uniform, and the SrRuO 3 The density of the target sample is 5.7g / cm 3 , the resistivity is 0.006Ω / Sq, which is a good electrical conductor. The strontium ruthenate target obtained in this embodiment can also be sputtered by DC plasma.

[0090] The atomic ratio Sr:Ru of Sr and Ru in the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com