Preparation method of flexible BNT (Bi(4-x)NdxTi3O12) ferroelectric-thin-film

A ferroelectric thin film, flexible technology, applied in the field of preparation of flexible BNT ferroelectric thin film, can solve the problems of poor fatigue performance of perovskite structure ferroelectric materials, poor thermal stability of the substrate, etc., to achieve solution concentration optimization and excellent ferroelectric performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

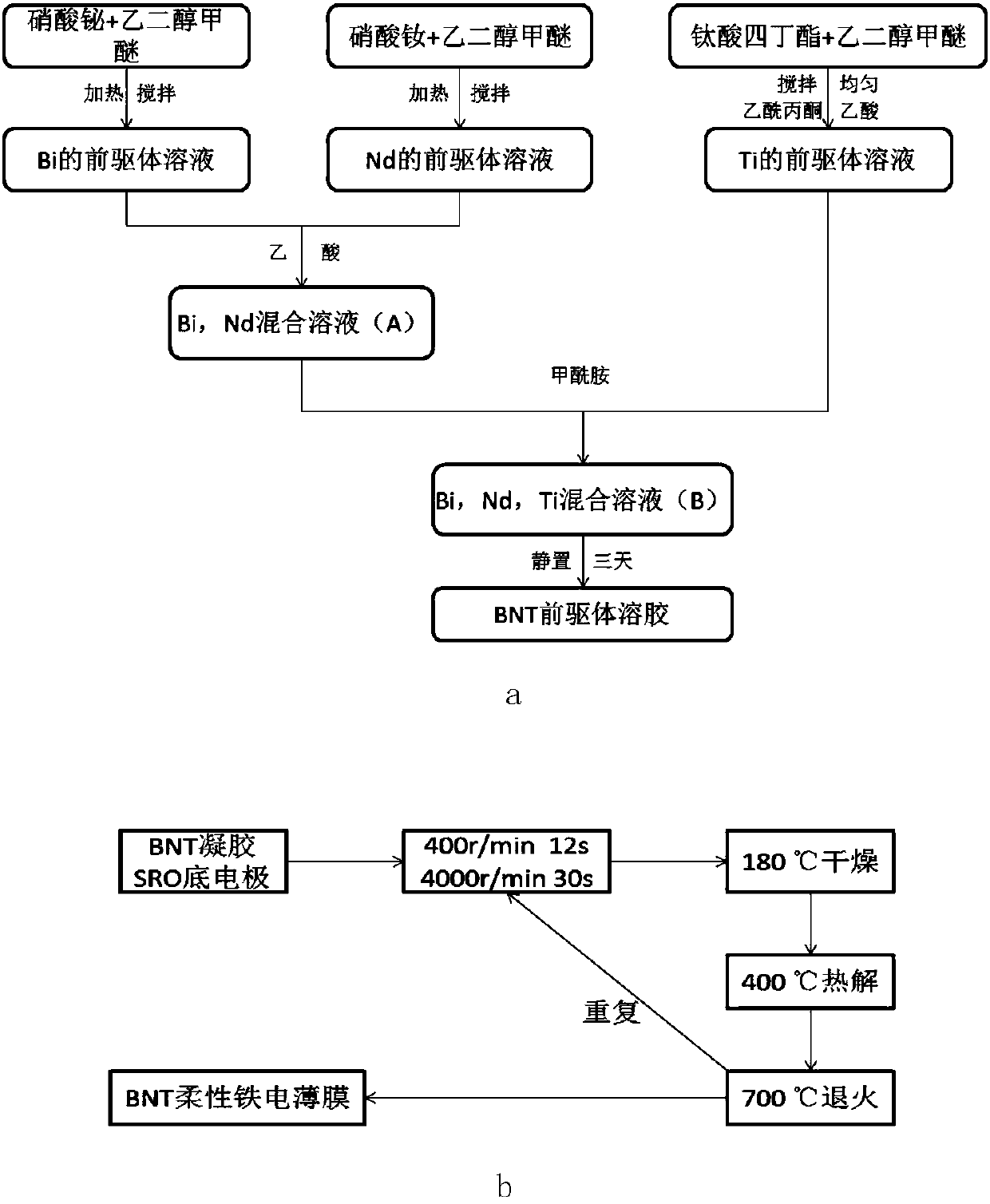

[0034] The technical solution of the present invention will be described in further detail below in conjunction with specific embodiments of the accompanying drawings.

[0035] A kind of method for preparing flexible BNT ferroelectric film by sol-gel method, is characterized in that, comprises the following steps:

[0036] 1.1 Preparation of single crystal muscovite sheet and preparation of bottom electrode: Select a smooth, crack-free, and impurity-free muscovite sheet, then paste the mica sheet on the operating table, and tear it off layer by layer with pointed tweezers until the single crystal flexible mica sheet The thickness is less than 50 μm; then a layer of cobalt ferrite CoFe is prepared on the upper single crystal flexible mica sheet by laser pulse deposition method 2 o 4 (hereinafter referred to as CFO) as a seed layer, and then a layer of SRO consistent with the ferroelectric material structure is grown on CFO, wherein the thickness of CFO is 10nm, and the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com