Barium titanate-strontium titanate nano composite film material and preparation method thereof

A nano-composite and thin-film material technology, applied in metal material coating process, ion implantation plating, superposition layer plating, etc., can solve the problems of no ferroelectric properties, large leakage current, and reduced insulation, and achieve The effect of good electrical performance, simple process and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Contains 2vol% SrRuO 3 Barium titanate-strontium ruthenate nanocomposite film

[0033] (1) Nb:SrTiO 3 (001) The substrate is ultrasonically cleaned in acetone and alcohol for 20 minutes, then heated to 750° C. in vacuum, and annealed for 30 minutes;

[0034] (2) Using the pulsed laser deposition method at a temperature of 750°C and an oxygen pressure of 15Pa, on Nb:SrTiO 3 (001) Deposit strontium ruthenate for 2 seconds on the substrate, then deposit barium titanate for 24 seconds;

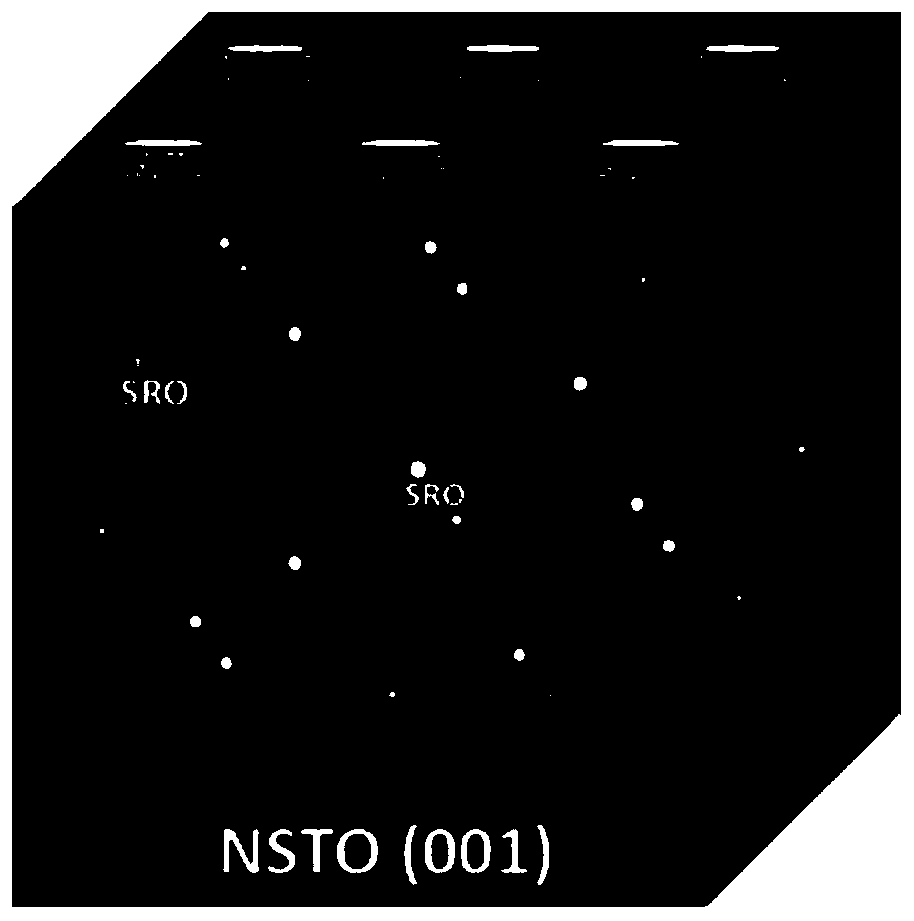

[0035] (3) The above process was repeated 40 times to prepare a barium titanate-strontium ruthenate nanocomposite film material with a thickness of 380 nm. The material has a crystal orientation of (001) plane, where, SrRuO 3 The volume ratio of the nanocomposite film is 2vol%, and the particles of nanometer size are uniformly distributed on the barium titanate substrate (see image 3 ). The remanent polarization of the film material is 14.1μC / cm 2 , the saturation polarization is 27...

Embodiment 2

[0037] Contains 4vol% SrRuO 3Barium titanate-strontium ruthenate nanocomposite film

[0038] (1) Using Nb:SrTiO 3 (001) Substrate. Microwave ultrasonically the substrate in acetone and alcohol for 20 minutes, then heat the substrate to 750°C in vacuum and keep it warm for 30 minutes;

[0039] (2) Using the pulsed laser deposition method at a temperature of 750°C and an oxygen pressure of 15Pa, on Nb:SrTiO 3 (001) Deposit strontium ruthenate for 4 seconds on the substrate, then deposit barium titanate for 23 seconds;

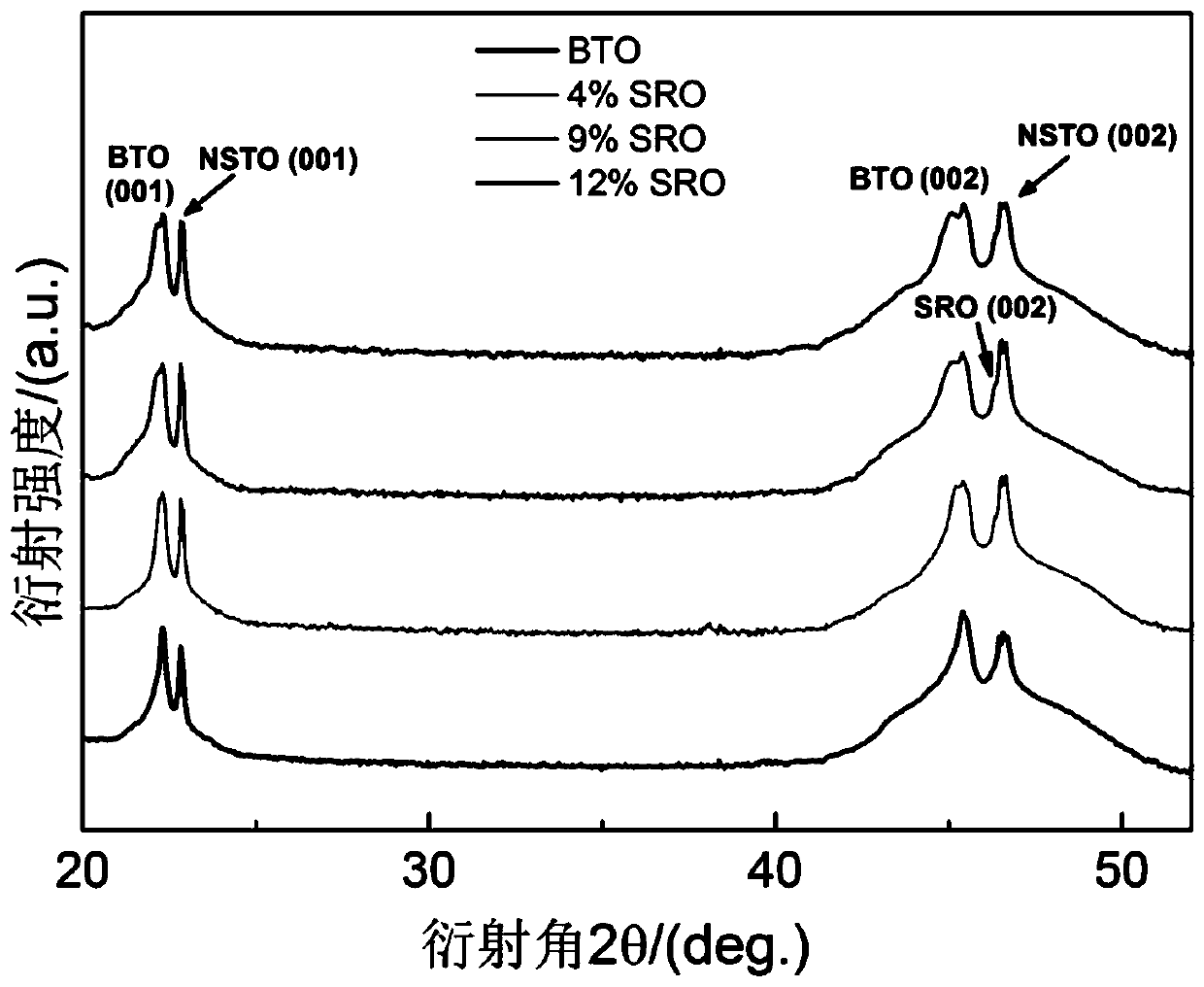

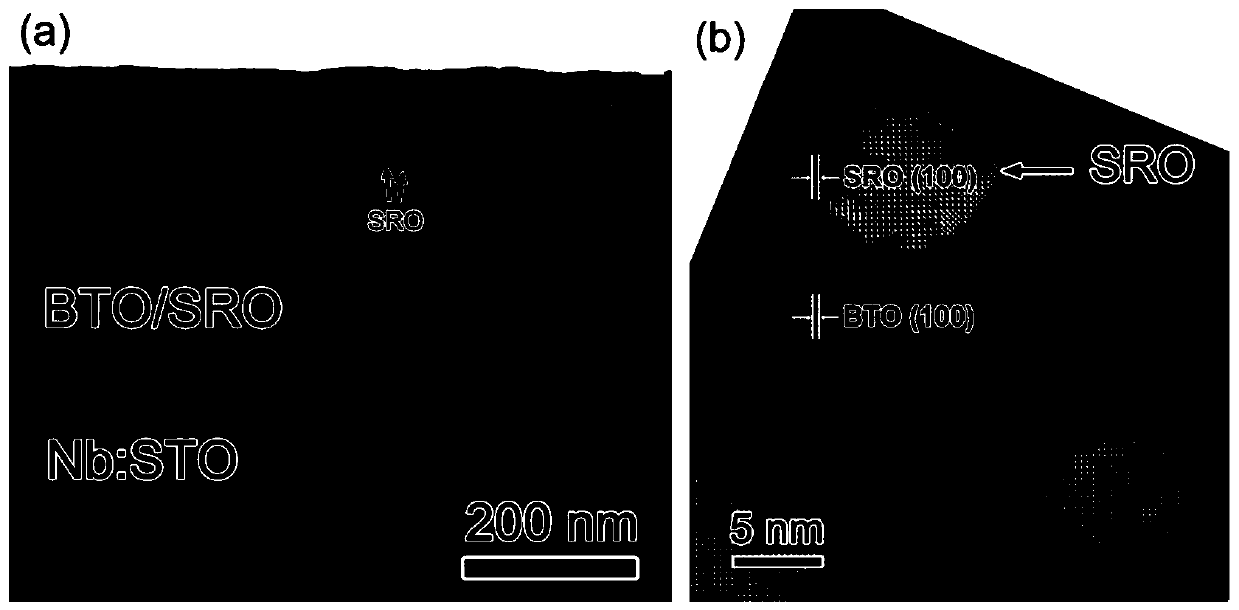

[0040] (3) The above process was repeated 40 times to prepare a barium titanate-strontium ruthenate nanocomposite film material with a thickness of 380 nm. The material has a crystal orientation of the (001) plane (see figure 1 ), among them, SrRuO 3 The volume ratio of the nanocomposite film is 4vol%, and the particles of nanometer size are uniformly distributed on the barium titanate substrate (see image 3 ). The remanent polarization of the film mater...

Embodiment 3

[0042] Contains 9vol% SrRuO 3 Barium titanate-strontium ruthenate nanocomposite film

[0043] (1) Using Nb:SrTiO 3 (001) Substrate. Microwave ultrasonically the substrate in acetone and alcohol for 20 minutes, then heat the substrate to 750°C in vacuum and keep it warm for 30 minutes;

[0044] (2) Using the pulsed laser deposition method at a temperature of 750°C and an oxygen pressure of 15Pa, on Nb:SrTiO 3 (001) Deposit strontium ruthenate for 9 seconds on the substrate, then deposit barium titanate for 22 seconds;

[0045] (3) The above process was repeated 40 times to prepare a barium titanate-strontium ruthenate nanocomposite film material with a thickness of 380 nm. The material has a crystal orientation of the (001) plane (see figure 1 ), among them, SrRuO 3 The volume ratio of the nanocomposite film is 9vol%, and its nanoparticles are evenly distributed on the barium titanate matrix (see figure 2 ). The remanent polarization of the film material is 40.3μC / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanent polarization | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com