Strontium ruthenate nanoparticle composite silver paste and preparation method thereof

A nanoparticle, strontium ruthenate technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems affecting the electrical properties of conductive silver paste, local agglomeration, etc., and achieve high photoelectric conversion efficiency , Good electrical performance, good soldering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Adopt the following method to prepare strontium ruthenate nanoparticle composite silver paste:

[0068] 1. Preparation of silver / strontium ruthenate complex: in the silver / strontium ruthenate complex, the content of strontium ruthenate is 0.2w%, and the balance is silver powder. The specific preparation method is as follows:

[0069] 1) Prepare 100mL of 0.1mol / L silver nitrate solution (A solution);

[0070] 2.) Prepare 100 mL of reducing solution (solution B), 1.056 g of ascorbic acid, 0.68 g of polyvinylpyrrolidone (PVP), 0.68 g of polyvinylpyrrolidone (PVP), deionized water as the solvent, and adjust the pH value of the reducing solution to 4 with 6% ammonia water;

[0071] 3) Add 0.2g of strontium ruthenate to solution B, stir for 15min, and sonicate for 15min;

[0072] 4) Keep solution B under stirring and ultrasonic, and add solution A to it co-currently and dropwise at a speed of 1ml / min;

[0073] 5) The solution after the reaction was completed was filtered an...

Embodiment 2~4

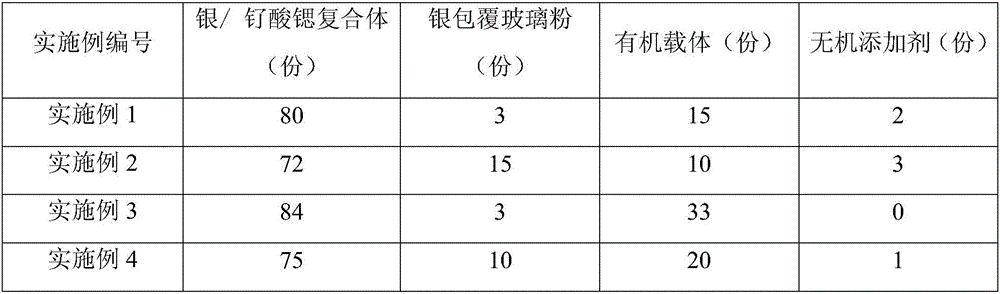

[0087] The silver / strontium ruthenate composite, the silver-coated glass powder, the organic carrier and the inorganic additives prepared in Example 1 were prepared according to the required proportions, and the proportions are shown in Table 1. Fully dispersing and mixing by a three-roll mill, performing a viscosity test, and adjusting the viscosity to obtain a strontium ruthenate nanoparticle composite silver paste with uniform dispersion and moderate viscosity.

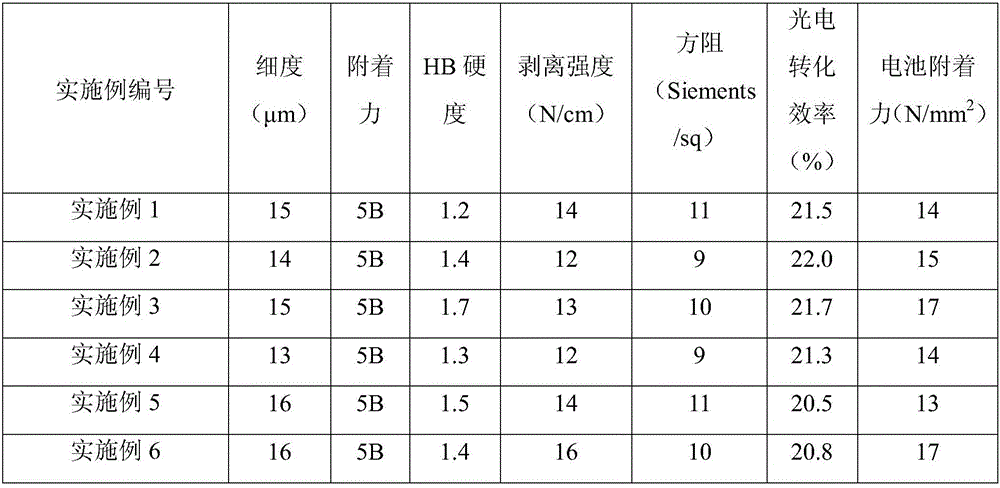

[0088] The obtained strontium ruthenate nanoparticle composite silver paste has no hard lumps after being stirred, and is in a uniform state, and has good soldering performance, and its performance test is shown in Table 2.

[0089] Table 1

[0090]

Embodiment 5

[0092] Using the method of Example 1, the only difference is that in the silver / strontium ruthenate composite, the content of strontium ruthenate is 0.02w%, and the balance is silver powder. The prepared strontium ruthenate nanoparticle composite silver paste has no hard lumps after stirring, and is in a uniform state, and has good soldering performance. The performance test is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com