Ir-doped SrRuO3 doped material, preparation method and application

A doping material, strontium ruthenate technology, applied in the field of magnetic storage, can solve the problems of small storage capacity and easy data loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

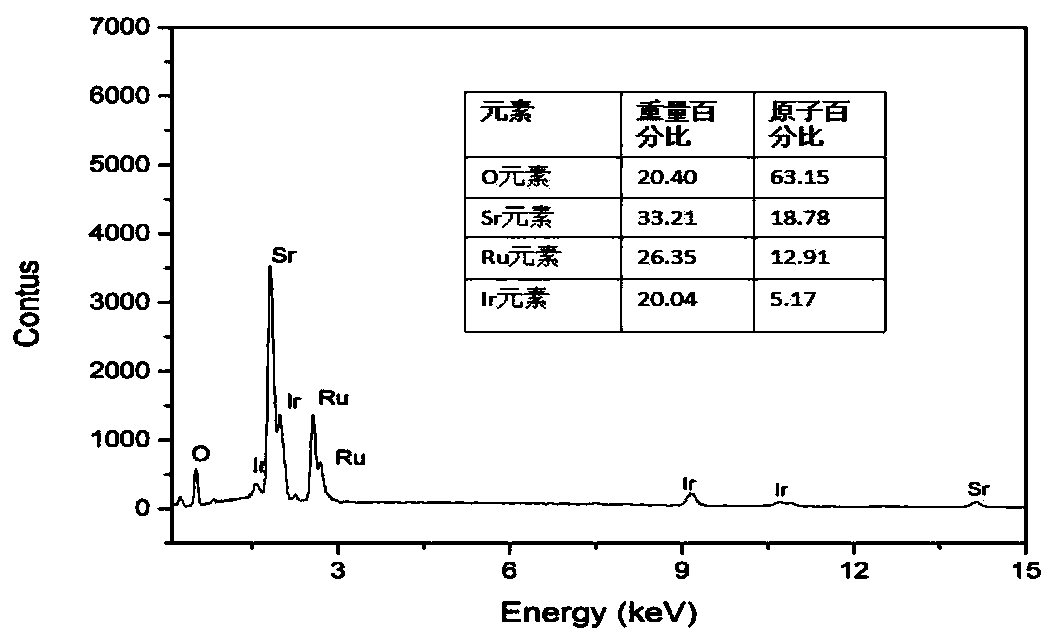

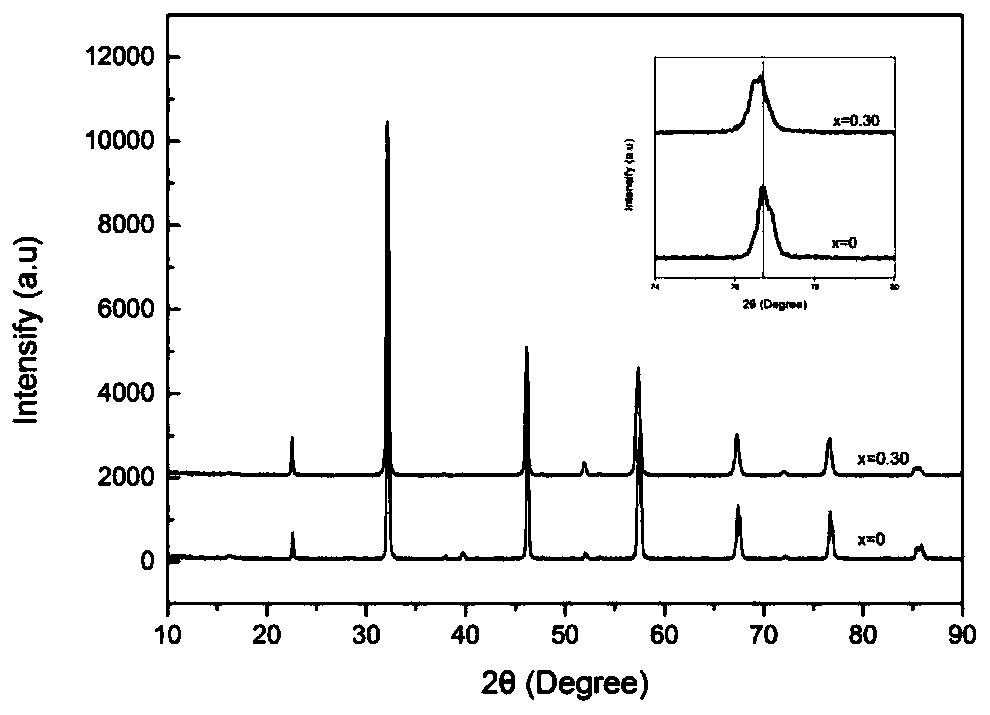

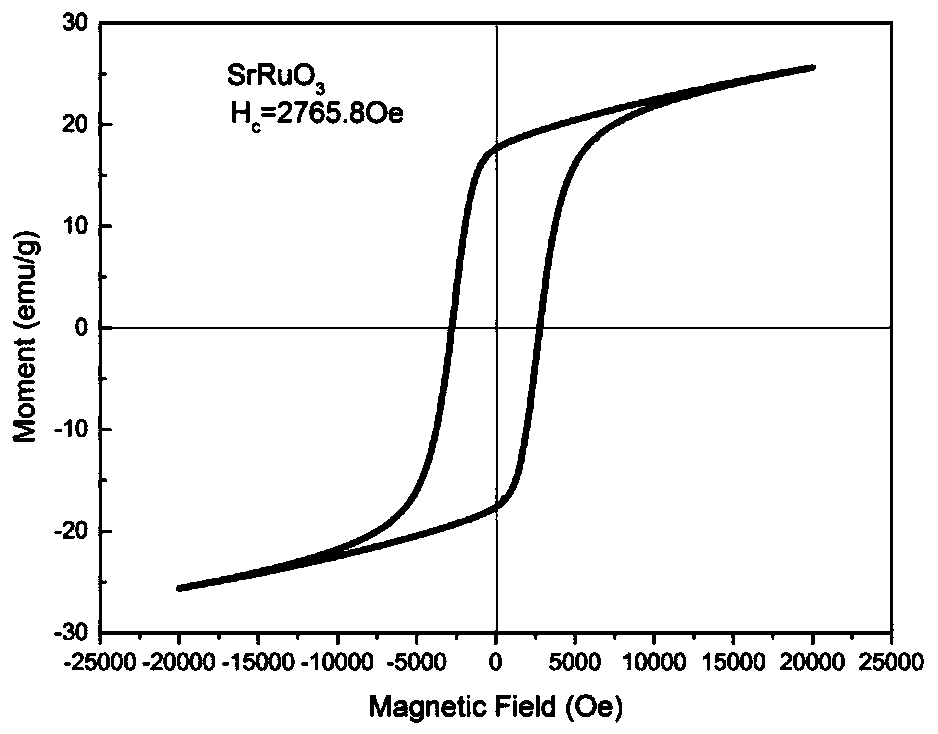

[0036] SrCO 3 , RuO 2 and Ir powder prepared by 1g SrRu 0.7 Ir 0.3 o 3 Ratio of sample 0.56g : 0.22g : 0.345g weighed, then mixed in an agate mortar and ground for 1 hour until evenly mixed, because Ru is volatile under high temperature conditions, the excess is 5% based on the original ratio.

[0037] Step 2: Sinter the uniformly mixed sample in a low-temperature furnace. The temperature is controlled as follows: increase to 1000°C at a rate of 5°C / min and keep for 24 hours, then cool down to 400°C at a rate of 6°C / min, then cool down naturally to room temperature.

[0038] Step 3: Take out the sample treated in step 2, put it into an agate mortar and grind it again for 60 minutes.

[0039] Step 4: Put the reground sample into a high-temperature furnace for sintering. The temperature is controlled as follows: the temperature is raised to 1200°C at a rate of 5°C / min and then kept for 24 hours, and then cooled to 400°C at a rate of 6°C / min. Cool to room temperature.

[...

Embodiment 2

[0042] SrCO 3 , RuO 2 and Ir powder prepared by 1g SrRu 0.7 Ir 0.3 o 3 Ratio of sample 0.56g : 0.22g : 0.35g weighed, then placed in an agate mortar and mixed and ground for 1 hour to mix evenly, because Ru is volatile under high temperature conditions, an excess of 5% based on the original ratio.

[0043] Step 2: Sinter the uniformly mixed sample in a low-temperature furnace. The temperature is controlled as follows: increase to 1000°C at a rate of 5°C / min and keep for 24 hours, then cool down to 400°C at a rate of 6°C / min, then cool down naturally to room temperature.

[0044] Step 3: Take out the sample treated in step 2, put it into an agate mortar and grind it again for 60 minutes.

[0045] Step 4: Put the reground sample into a high-temperature furnace for sintering. The temperature is controlled as follows: the temperature is raised to 1200°C at a rate of 5°C / min and then kept for 24 hours, and then cooled to 400°C at a rate of 6°C / min. Cool to room temperature. ...

Embodiment 3

[0048] SrCO 3 , RuO 2 and Ir powder prepared by 1g SrRu 0.7 Ir 0.3 o 3 Ratio of sample 0.56g : 0.22g : 0.355g Weigh, then put in an agate mortar and mix and grind for 1h until the mix is uniform, because Ru is volatile under high temperature conditions, the excess is 5% based on the original ratio.

[0049] Step 2: Sinter the uniformly mixed sample in a low-temperature furnace. The temperature is controlled as follows: increase to 1000°C at a rate of 5°C / min and keep for 24 hours, then cool down to 400°C at a rate of 6°C / min, then cool down naturally to room temperature.

[0050] Step 3: Take out the sample treated in step 2, put it into an agate mortar and grind it again for 60 minutes.

[0051] Step 4: Put the reground sample into a high-temperature furnace for sintering. The temperature is controlled as follows: the temperature is raised to 1200°C at a rate of 5°C / min and then kept for 24 hours, and then cooled to 400°C at a rate of 6°C / min. Cool to room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com