A method for preparing manganese-bismuth alloy film with room temperature exchange bias effect

A technology of alloy thin film and bias effect, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of small room temperature exchange bias field and no exchange bias field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

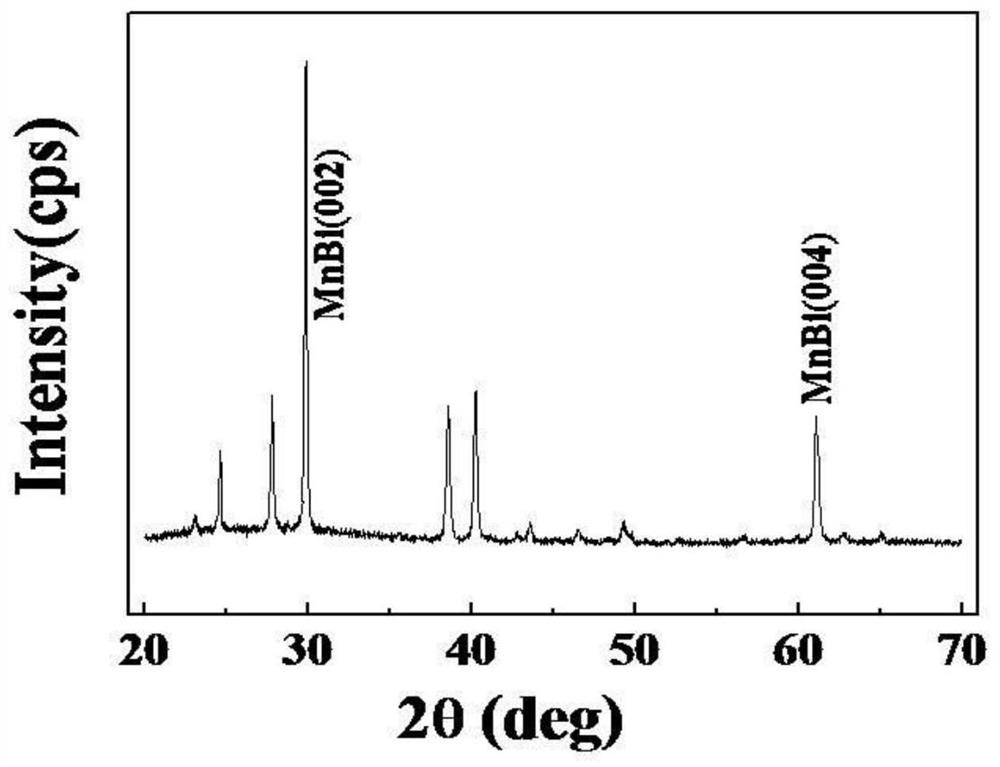

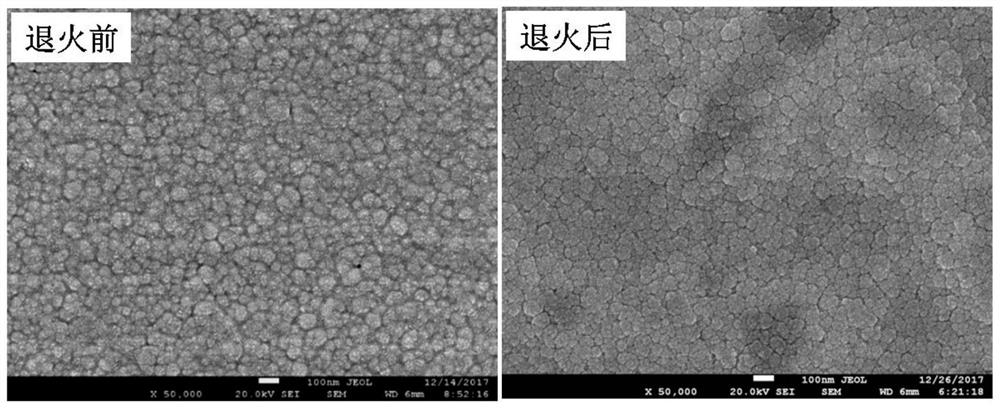

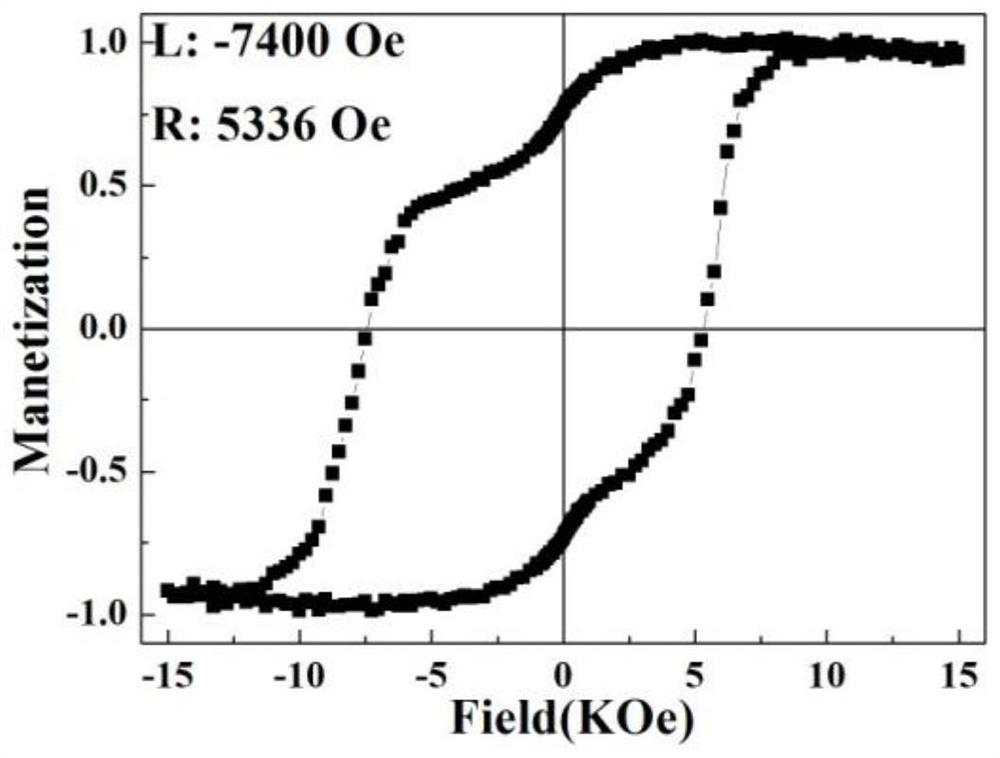

[0030] The present embodiment provides a method for preparing a manganese-bismuth alloy thin film with room temperature exchange bias effect, comprising the following steps:

[0031] Main preparation conditions: Mn sputtering power is 35W, Bi sputtering power is 8W, sputtering pressure is 2.3Pa, sputtering time is 2400s, annealing background vacuum is 1.0×10 -4 Pa, the annealing temperature is 380℃, and the annealing time is 2h;

[0032] Put Mn and Bi targets with a diameter of 60 mm and a purity of 99.99% and a glass substrate cleaned in advance into the magnetron sputtering chamber. Wait until the background vacuum of the vacuum chamber reaches 8.0×10 -5 When Pa, argon with a purity of 99.99% was introduced, and the flow rate of argon was adjusted to 80sccm. At the same time, the baffle valve was adjusted so that the sputtering pressure was 2.3Pa, the sputtering power of Mn was 35W, and the sputtering power of Bi was 8W. and sputtering at the same time, the sputtering time...

Embodiment 2

[0039] The present embodiment provides a method for preparing a manganese-bismuth alloy thin film with room temperature exchange bias effect, comprising the following steps:

[0040] Main preparation conditions: Mn sputtering power is 30W, Bi sputtering power is 8W, sputtering pressure is 2.3Pa, sputtering time is 2400s, annealing background vacuum is 1.0×10 -4 Pa, the annealing temperature is 380℃, and the annealing time is 2h;

[0041] Put Mn and Bi targets with a diameter of 60 mm and a purity of 99.99% and a glass substrate cleaned in advance into the magnetron sputtering chamber. Wait until the background vacuum of the vacuum chamber reaches 8.0×10 -5 When Pa, argon gas with a purity of 99.99% was introduced, the flow rate of argon gas was adjusted to 80sccm, and the baffle valve was adjusted to make the sputtering pressure 2.3Pa, the Mn sputtering power to be 30W, and the Bi sputtering power to be 8W. Sputtering, the sputtering time is 2400s; then the substrate after s...

Embodiment 3

[0044] The present embodiment provides a method for preparing a manganese-bismuth alloy thin film with room temperature exchange bias effect, comprising the following steps:

[0045] The main preparation conditions: Mn sputtering power is 28W, Bi sputtering power is 8W, sputtering pressure is 2.3Pa, sputtering time is 2400s, annealing background vacuum is 1.0×10-4 Pa, the annealing temperature is 380℃, and the annealing time is 2h;

[0046] Put Mn and Bi targets with a diameter of 60 mm and a purity of 99.99% and a glass substrate cleaned in advance into the magnetron sputtering chamber. The background vacuum of the vacuum chamber reaches 8.0×10 -5 When Pa, argon gas with a purity of 99.99% was introduced, and the flow rate of argon gas was adjusted to 80sccm. At the same time, the baffle valve was adjusted so that the sputtering pressure was 2.3Pa, the Mn sputtering power was 28W, and the Bi sputtering power was 8W. Sputtering, the sputtering time is 2400s; then the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com