A strontium ruthenate/lanthanum strontium manganese oxide transition metal oxide heterojunction and preparation method thereof

A technology of lanthanum strontium manganese oxide and transition metal, which is applied in the data storage field of functional oxide thin film materials, can solve the problems of uncontrollable size and direction of exchange bias, achieve precise controllable size and direction of exchange bias, and has application prospects Broad, ductile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

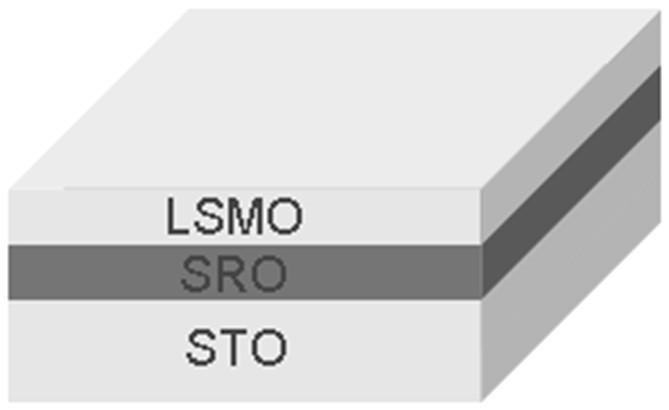

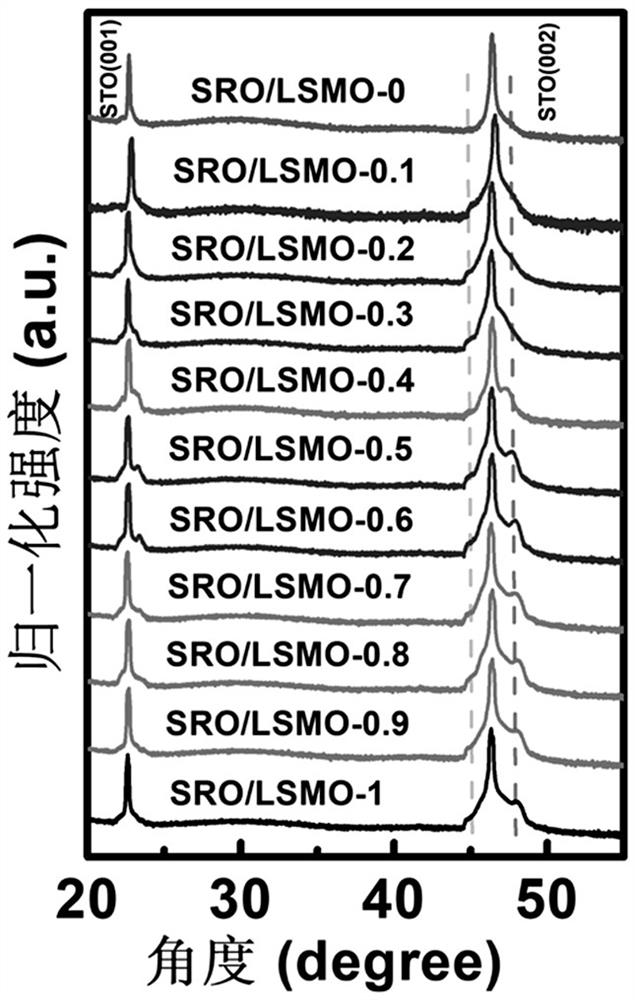

[0046]The preparation steps of any SRO / LSMO-0 (SRO / LMO) transition metal oxide heterojunction thin film material are:

[0047](1) Prepare pure-phase SRO and LSMO-0 targets (that is, LMO targets) using the aforementioned solid-state sintering method, and place each target in the deposition chamber of the pulsed laser deposition equipment for standby;

[0048](2) SrTiO3(001) The single crystal substrate was ultrasonically cleaned in acetone and alcohol solution for 20 min each, and the SrTiO3(001) The single crystal substrate is heated to 750°C under vacuum and kept for 30 min;

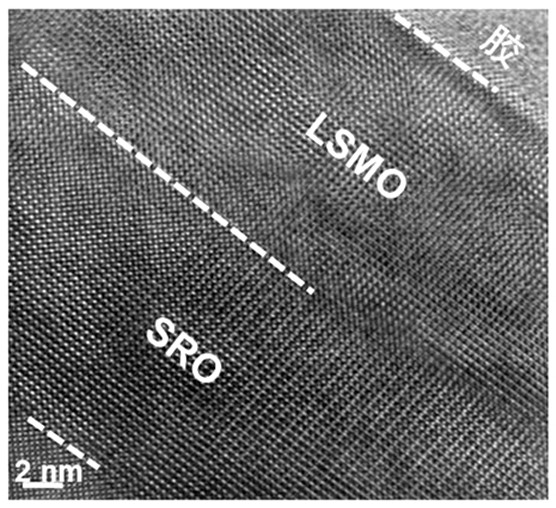

[0049](3) Using pulsed laser deposition method under the conditions of substrate temperature and oxygen pressure of 750℃ and 40 Pa, respectively, adjust the distance between target and substrate to 4.5 cm, and use energy density to 1.5J / cm2The pulsed laser first bombards the SRO target, and the SrTiO3(001) A single-layer SRO film with a thickness of 15 nm is prepared on a single crystal substrate, and under the same c...

Embodiment 2

[0053]The preparation steps of any SRO / LSMO-0.1 transition metal oxide heterojunction thin film material according to the operating method of Example 1 are:

[0054](1) Prepare SRO and LSMO-0.1 targets by the aforementioned solid-state sintering method, and place each target in the deposition chamber of the pulsed laser deposition equipment for use;

[0055](2) SrTiO3(001) Single crystal substrates were ultrasonically cleaned in acetone and alcohol solution for 20 min each, SrTiO before deposition3(001) The single crystal substrate is heated to 750°C under vacuum and kept for 30 min;

[0056](3) Using pulsed laser deposition method under the conditions of substrate temperature and oxygen pressure of 750℃ and 40 Pa, respectively, adjust the distance between target and substrate to 4.5 cm, and use energy density to 1.5J / cm2The pulsed laser first bombards the SRO target, and the SrTiO3(001) A single-layer SRO film with a thickness of 15 nm is prepared on a single crystal substrate, and under th...

Embodiment 3

[0060]The preparation steps of any SRO / LSMO-0.2 transition metal oxide heterojunction thin film material according to the operating method of Example 1 are:

[0061](1) Prepare SRO and LSMO-0.2 targets using the aforementioned solid-state sintering method, and place each target in the deposition chamber of the pulsed laser deposition equipment for use;

[0062](2) SrTiO3(001) Single crystal substrates were ultrasonically cleaned in acetone and alcohol solution for 20 min each, SrTiO before deposition3(001) The single crystal substrate is heated to 750°C under vacuum and kept for 30 min;

[0063](3) Using pulsed laser deposition method under the conditions of substrate temperature and oxygen pressure of 750℃ and 40 Pa, respectively, adjust the distance between target and substrate to 4.5 cm, and use energy density to 1.5J / cm2The pulsed laser first bombards the SRO target, and the SrTiO3(001) A single-layer SRO film with a thickness of 15 nm is prepared on a single crystal substrate, and under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com