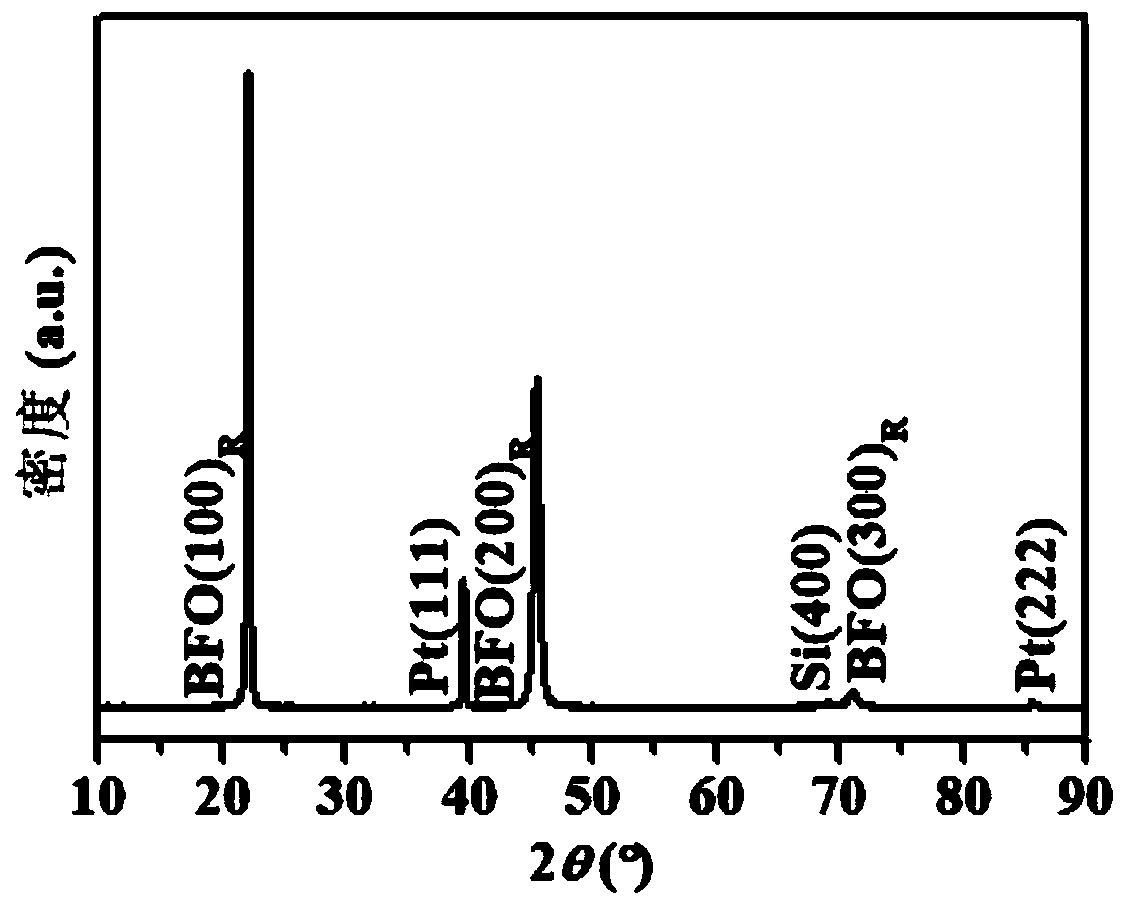

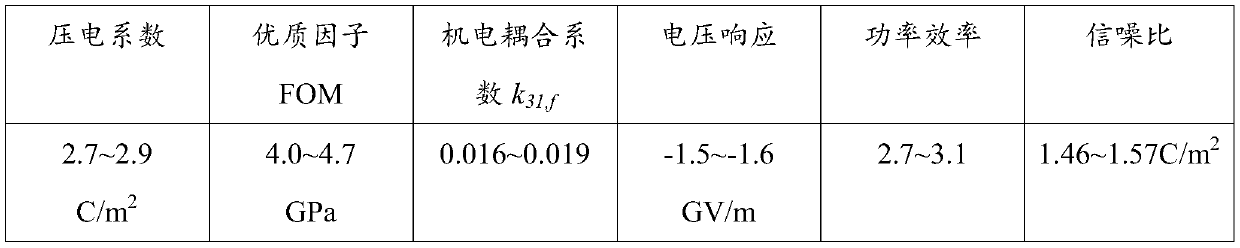

Bismuth ferrite film material, method for integrally preparing bismuth ferrite film on silicon substrate at low temperature and application

A bismuth ferrite, silicon-based technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of unstable chemical valence and element stoichiometric ratio, and difficulty in obtaining hysteresis of bismuth ferrite film. Line, aggravate leakage, interface diffusion and other problems, to achieve the effects of low cost, reduced volatilization, and easy device integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (a) Treatment of the substrate

[0050] Semiconductor Si / SiO 2 As the substrate, put it into the sample tray, and then put the sample tray into the sample tray rack of the vacuum coating chamber;

[0051] Vacuuming: close the vacuum chamber, evacuate, and make the air pressure in the chamber to ~10 -4 Pa;

[0052] Heating: Introduce Ar into the chamber, the air pressure is 2.3Pa, and then heat the substrate until the temperature rises to 350°C, and then keep the temperature stable.

[0053] (b) Preparation of the bottom electrode

[0054] The bottom electrode was deposited by radio frequency magnetron sputtering with titanium and platinum as sputtering targets. The sputtering gas pressure is adjusted to 0.3Pa, the sputtering power is 55W, and the substrate is sequentially deposited with a total thickness of 150nm.

[0055] (c) Preparation of buffer layer

[0056] The buffer layer was deposited by radio frequency magnetron sputtering with lanthanum nickel oxide cer...

Embodiment 2

[0066] The difference between this embodiment and embodiment 1 is that in step (a), the heating temperature is 400°C.

Embodiment 3

[0068] The difference between this embodiment and embodiment 1 is that in step (d), the thickness of the bismuth ferrite is 60nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com