BNT-BA-KNN leadless ferroelectric phase change ceramic and preparation method thereof

A ferroelectric ceramic and ferroelectric technology, which is applied in the field of lead-free ferroelectric ceramic materials and their ceramic components, and ferroelectric ceramic materials, can solve the problems of ceramic depolarization and achieve the effect of large remanent polarization intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the ferroelectric phase change ceramic material with ferroelectric-antiferroelectric (FE-AFE) phase transition according to the present invention specifically includes the following steps.

[0031] First of all, ceramic powder can be prepared by solid phase method. Oxides or carbonates of metal elements in chemical composition, such as Bi 2 o 3 、Na 2 CO 3 、TiO 2 、Al 2 o 3 、K 2 CO 3 , Nb 2 o 5 Powder is the raw material, according to 0.97((1-x)Bi 0.5 Na 0.5 TiO 3 -xBiAlO 3 )-0.03K 0.5 Na 0.5 NbO 3 The stoichiometric ratio of the corresponding elements is formulated. Mix with wet ball milling method, in the described wet ball milling method mixing, according to the mass ratio of raw material:ball:alcohol=1:(1.8~2.2):(0.8~1.2), mix material 23~25 hours, wherein ball milling medium It is zirconium ball or agate ball. After drying, sieve, select the powder with suitable particle size and press it into agglomerates, and raise the t...

Embodiment 1

[0037] The composition of ferroelectric ceramic materials with ferroelectric-antiferroelectric (FE-AFE) phase transition is 0.97(0.96Bi 0.5 Na 0.5 TiO 3 -0.04BiAlO 3 )-0.03K 0.5 Na 0.5 NbO 3 ;

[0038] (1) Calculate the composition Bi in the powder raw material according to the composition of the above chemical formula 2 o 3 、Na 2 CO 3 、TiO 2 、Al 2 o 3 、K 2 CO 3 and Nb 2 o 5 The quality of the mixture is prepared according to the composition ratio, mixed by wet ball milling, and mixed for 24 hours according to the mass ratio of raw materials: ball: alcohol = 1:2:1, so that each component is mixed evenly. After drying, pass through a 40-mesh sieve, briquette, and heat up to 850°C at a heating rate lower than 2°C / min in an air atmosphere, and keep it warm for 2 hours to synthesize a composition of 0.97 (0.96Bi 0.5 Na 0.5 TiO 3 -0.04BiAlO 3 )-0.03K 0.5 Na 0.5 NbO 3 ceramic powder;

[0039] (2) Grinding the ceramic powder obtained in step (1) and passing th...

Embodiment 2

[0045] The composition of ferroelectric ceramic materials with ferroelectric-antiferroelectric (FE-AFE) phase transition is 0.97(0.99Bi 0.5 Na 0.5 TiO 3 -0.01BiAlO 3 )-0.03K 0.5 Na 0.5 NbO 3 ;

[0046] Repeat the preparation method of Example 1 by the above-mentioned formula.

[0047] The hysteresis loop test at room temperature was performed on the ceramic element of this embodiment, and the test results are shown in Table 1.

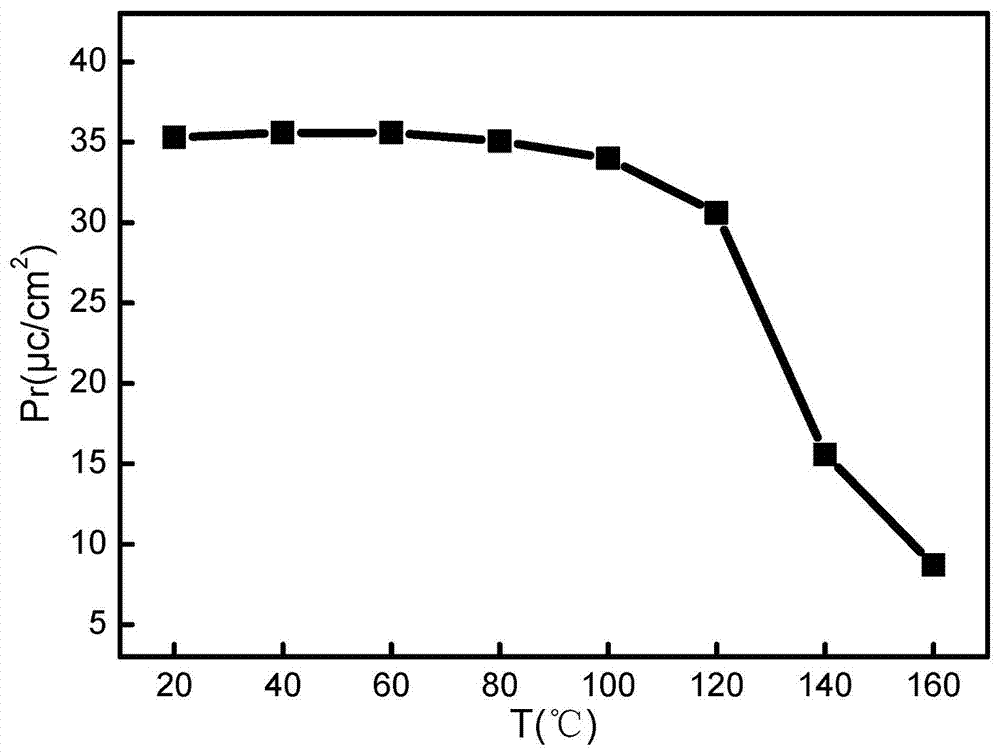

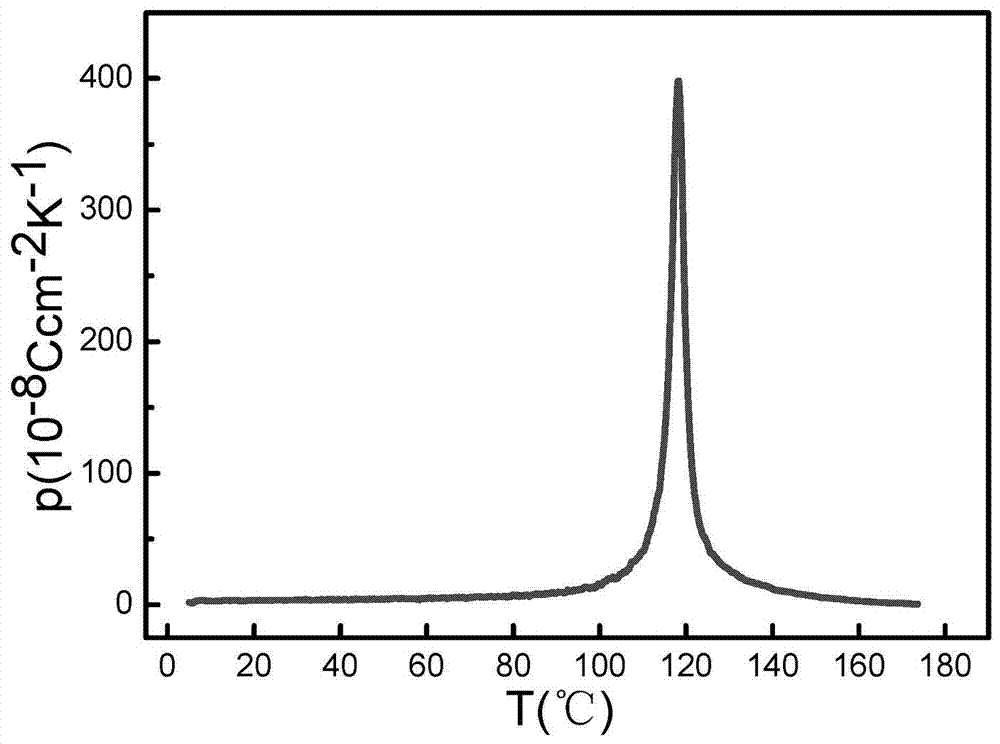

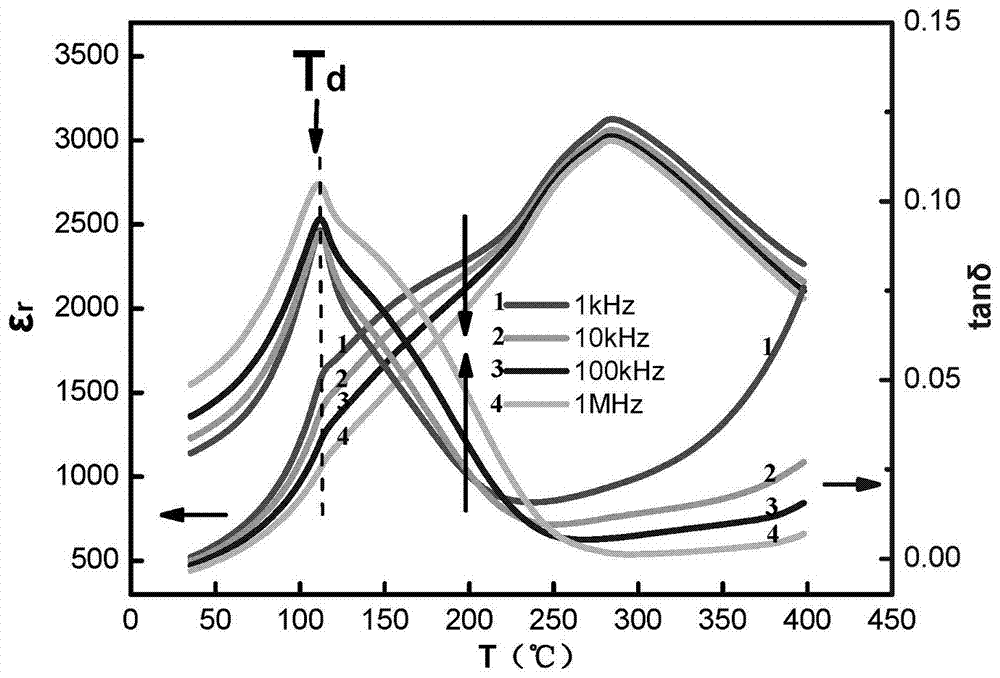

[0048] The ceramic element of the present embodiment has carried out the measurement of electric hysteresis loop under different temperatures, and measurement result is as follows Figure 2a and Figure 2b . Figure 2a It is the hysteresis loop of the ceramic element obtained in Example 2 at different temperatures. It can be seen that as the temperature increases, the coercive field E C Gradually decreases, the remnant polarization (P r ) remain stable until 120°C. this is in Figure 2b It is also reflected in , indicating that ceramic com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com