Method for producing flexible package lithium ion battery negative plates

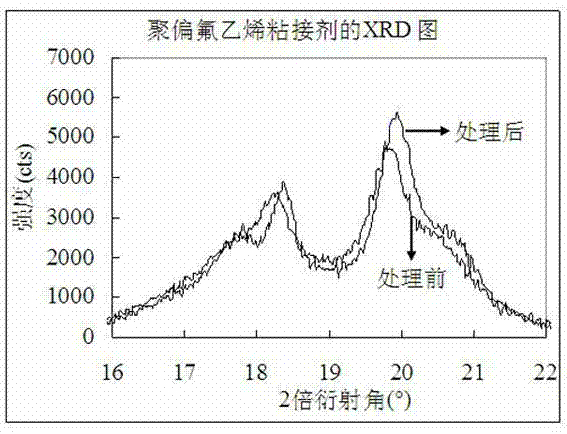

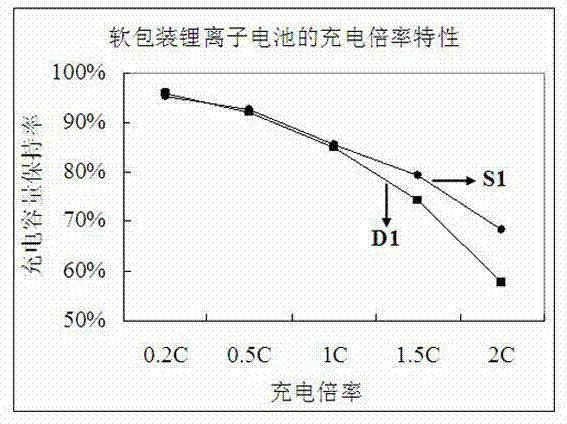

A technology of lithium-ion batteries and manufacturing methods, which is applied in the field of manufacturing negative electrodes of flexible-packaged lithium-ion batteries, can solve the problems of large cycle expansion and short cycle life, and achieve the advantages of reducing cycle expansion, improving adhesive performance, and strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

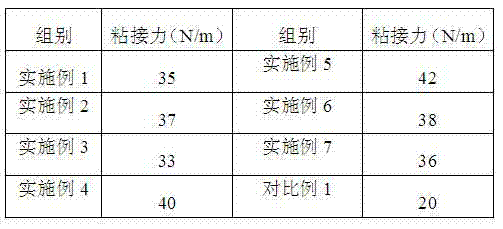

Embodiment 1

[0026] Embodiment 1, a method for manufacturing a negative electrode sheet of a flexible package lithium ion battery provided in this embodiment, the negative electrode sheet includes a negative electrode current collector and a negative electrode diaphragm coated on the surface of the negative electrode current collector, the method includes the following steps:

[0027] Step 1: Add artificial graphite, polyvinylidene fluoride binder (final melting temperature of 170°C) and conductive carbon to the solvent N-methylpyrrolidone in a mass ratio of 96:2:2, and mix well to obtain negative electrode slurry , and then coating the negative electrode slurry on the negative electrode current collector, forming a negative electrode membrane on the negative electrode current collector after drying, and obtaining a negative electrode sheet to be baked after cold pressing.

[0028] Step 2, place the negative electrode sheet to be baked in a vacuum oven for baking, the temperature in the vac...

Embodiment 2

[0030] Embodiment 2, a method for manufacturing a flexible lithium-ion battery negative electrode sheet provided in this embodiment, the negative electrode sheet includes a negative electrode current collector and a negative electrode diaphragm coated on the surface of the negative electrode current collector, the method includes the following steps:

[0031] Step 1: Add natural graphite, polyvinylidene fluoride binder (final melting temperature of 155°C) and superconducting carbon into the solvent N-methylpyrrolidone in a mass ratio of 94:3:3, and mix well to obtain the negative electrode slurry Then, the negative electrode slurry is coated on the negative electrode collector, and after drying, the negative electrode membrane is formed on the negative electrode collector, and the negative electrode sheet to be baked is obtained after cold pressing.

[0032] Step 2, place the negative electrode sheet to be baked in a vacuum oven, the temperature in the vacuum oven is 160°C, the...

Embodiment 3

[0034] Embodiment 3, a method for manufacturing a flexible lithium-ion battery negative electrode sheet provided in this embodiment, the negative electrode sheet includes a negative electrode current collector and a negative electrode diaphragm coated on the surface of the negative electrode current collector, the method includes the following steps:

[0035]Step 1: Add mesophase carbon microspheres, polyvinylidene fluoride adhesive (final melting temperature: 180°C) and acetylene black light in a mass ratio of 90:5:5 to the solvent N-methylpyrrolidone, and mix well to obtain Negative electrode slurry, and then coating the negative electrode slurry on the negative electrode collector, forming a negative electrode membrane on the negative electrode collector after drying, and obtaining the negative electrode sheet to be baked after cold pressing.

[0036] Step 2, put the negative electrode sheet to be baked in a vacuum oven, the temperature in the vacuum oven is 200°C, the bakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com