Photosensitive ferroelectric polymer composite film and preparation method thereof, and ferroelectric device or piezoelectric device using composite film

A composite film and polymer technology, applied in the field of flexible electronics and optoelectronic materials, can solve the problems of damage to the mechanical flexibility of materials, the inability to have both flexibility and strong polarization, and the limited increase in electric polarization strength, and achieve both ferroelectricity , stable luminescent properties, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

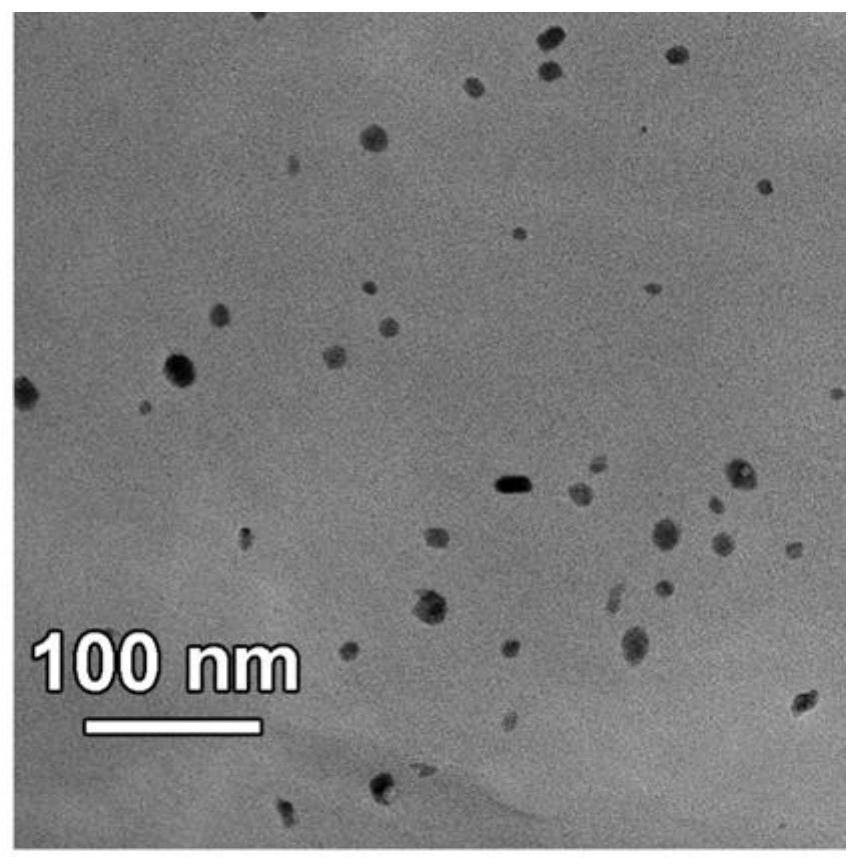

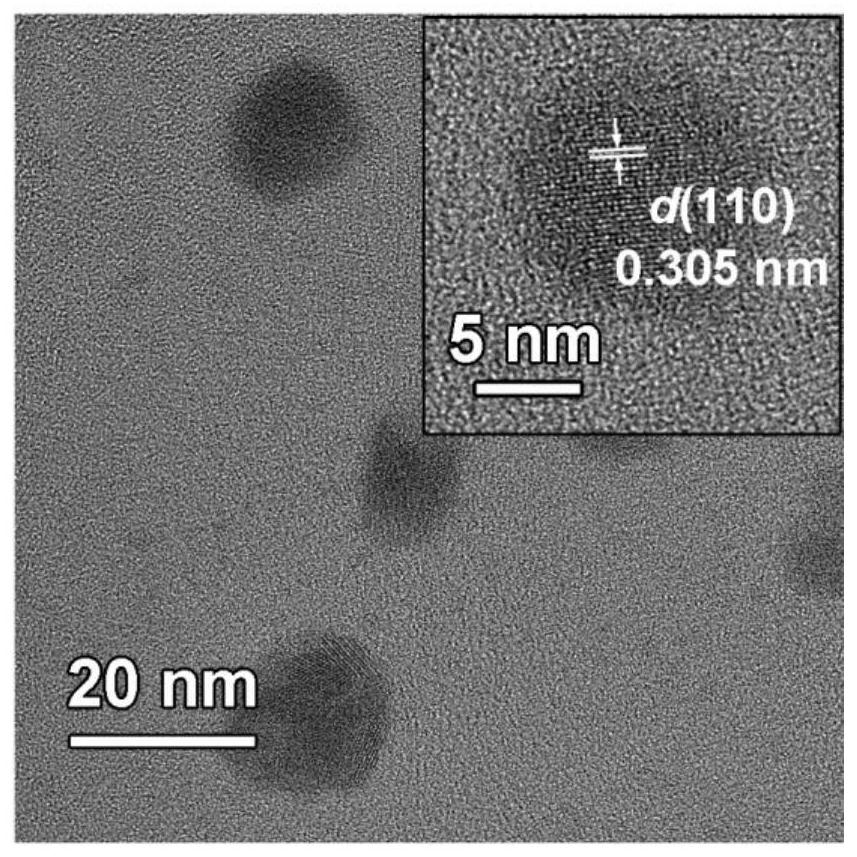

[0109] The second aspect of the present invention provides a kind of preparation method of composite thin film, comprise (1) organic salt and inorganic salt are dissolved in the organic solvent, obtain the step of perovskite precursor solution; (2) in described perovskite Adding the powder of the polymer matrix to the ore precursor solution and stirring to obtain a perovskite precursor-polymer mixed solution; (3) preheating the mixed solution to obtain a preheated mixed solution; (4 ) a step of casting the preheated mixed solution to obtain a coating film; (5) vacuum drying the coating film to obtain a composite film.

[0110] (1) Dissolving organic salt and inorganic salt in organic solvent to obtain the step of perovskite precursor solution

[0111] Organic salts may include organic halide salts, which may be salts including organic cations and halide ions. Organic cations can include CH 3 NH 3 + 、CH(NH 2 ) 2 + 、C 4 h 12 N + 、C 16 h 36 N + one or a combination o...

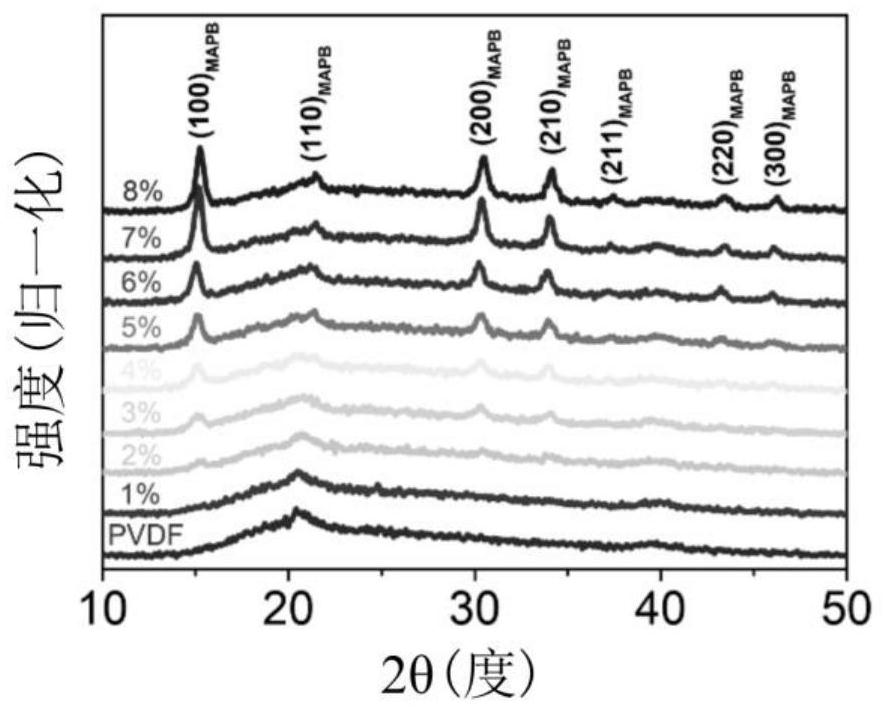

Embodiment 1

[0131] Prepare the MAPB / PVDF-1 composite film that MAPB content is 1 mass % by the following steps:

[0132] (1) PVDF (Shanghai Sanaifu New Material Co., Ltd., molecular weight 5×10) will be stored 5 g / mol, density 1.77g / cm 3 ) The glass jar of the powder was put into an air blast oven at 80°C with the open mouth, and kept standing for more than 12 hours to remove traces of water adsorbed in the polymer.

[0133] (2) As shown in Table 1, accurately weigh 0.00472g methylamine bromide (CH 3 NH 3 Br, namely, MABr, white crystal, Xi'an Bao Lai Te Optoelectronics Particle Co., Ltd.) and 0.01548g lead bromide (PbBr 2 , white powder, Aladdin Reagent Co., Ltd.) and placed in a 50mL beaker, add 20mL of N,N-dimethylformamide (hereinafter referred to as "DMF", Beijing Chemical Plant), and use medium-speed magnetic force at room temperature Stir for 10 minutes until completely dissolved.

[0134] (3) Increase the magnetic stirring speed to high speed, pour 2.00000g of weighed PVDF po...

Embodiment 2

[0160] In addition to changing the amount of methylamine bromide and lead bromide raw materials as shown in Table 1 to change the content of filler particles in the composite film, the composite film MAPB / PVDF-2 of Example 2 was prepared in the same manner as in Example 1 . The same tests as for the composite film of Example 1 were carried out. The results are shown in Tables 2-5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com