Red fluorescent body and light-emitting device

A technology of red fluorescence and light-emitting elements, which is applied in the field of red phosphors, can solve problems such as low luminous rate and increased spectral components, and achieve the effects of stable luminous characteristics and suppression of deviations in luminous characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] As the raw material of the phosphor of Example 1, α-type silicon nitride powder (Si 3 N 4 , Ube Industries, Ltd. SN-E10 grade), calcium nitride powder (Ca 3 N 2 , manufactured by Materion Corporation), aluminum nitride powder (AlN, Grade E manufactured by Tokuyama Corporation), europium oxide (Eu 2 o 3 , Shin-Etsu Chemical Industry Co., Ltd. RU grade).

[0059] First, Si in the raw material 3 N 4 , AlN, Eu 2 o 3 Dry mixing was performed with a V-blender for 10 minutes. In order to make the mixed raw materials uniform in size, the mixed raw materials were classified with a nylon sieve with a mesh size of 250 μm to prepare a raw material mixture.

[0060] The raw material mixture that has passed through the sieve is moved to a glove box capable of maintaining a nitrogen atmosphere of 1 mass ppm or less of moisture and 1 mass ppm of oxygen or less, in which Ca 3 N 2 Compounded into raw material mix, dry blended. In order to make the dry-blended raw materials un...

Embodiment 2

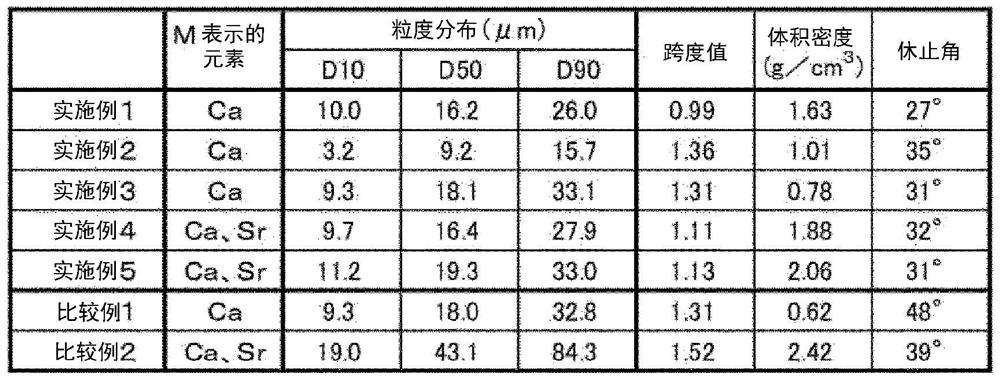

[0072] The phosphor powder of Example 2 was produced under the same conditions as in Example 1 except that the crushing and classification conditions were changed so as to be D10, D50 (mass median diameter), and D90 shown in Table 1. The properties of the phosphor obtained in Example 2 are shown in Table 1 together with the results of Example 1.

Embodiment 3

[0074] Grinding and classification conditions were changed so as to become D10, D50 (mass median particle size), and D90 shown in Table 1, and washing based on ethanol aqueous solution was added after acid washing, and prepared under the same conditions as in Example 1 except that Phosphor powder of Example 3. The characteristics of the phosphor obtained in Example 3 are also shown in Table 1 together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com