Ultrasonic probe and production method thereof

A manufacturing method and ultrasonic technology, which is applied in the field of ultrasonic probes, can solve problems such as the decrease of the transmission characteristics of the detection signal, the increase of the electrical impedance of the vibrator, and the reduction of the size of the vibrator, so as to improve the electromechanical coupling coefficient, reduce the electrical impedance, and reduce the acoustic impedance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below with reference to the drawings. In addition, the same reference numerals are assigned to the same constituent elements, and description thereof will be omitted.

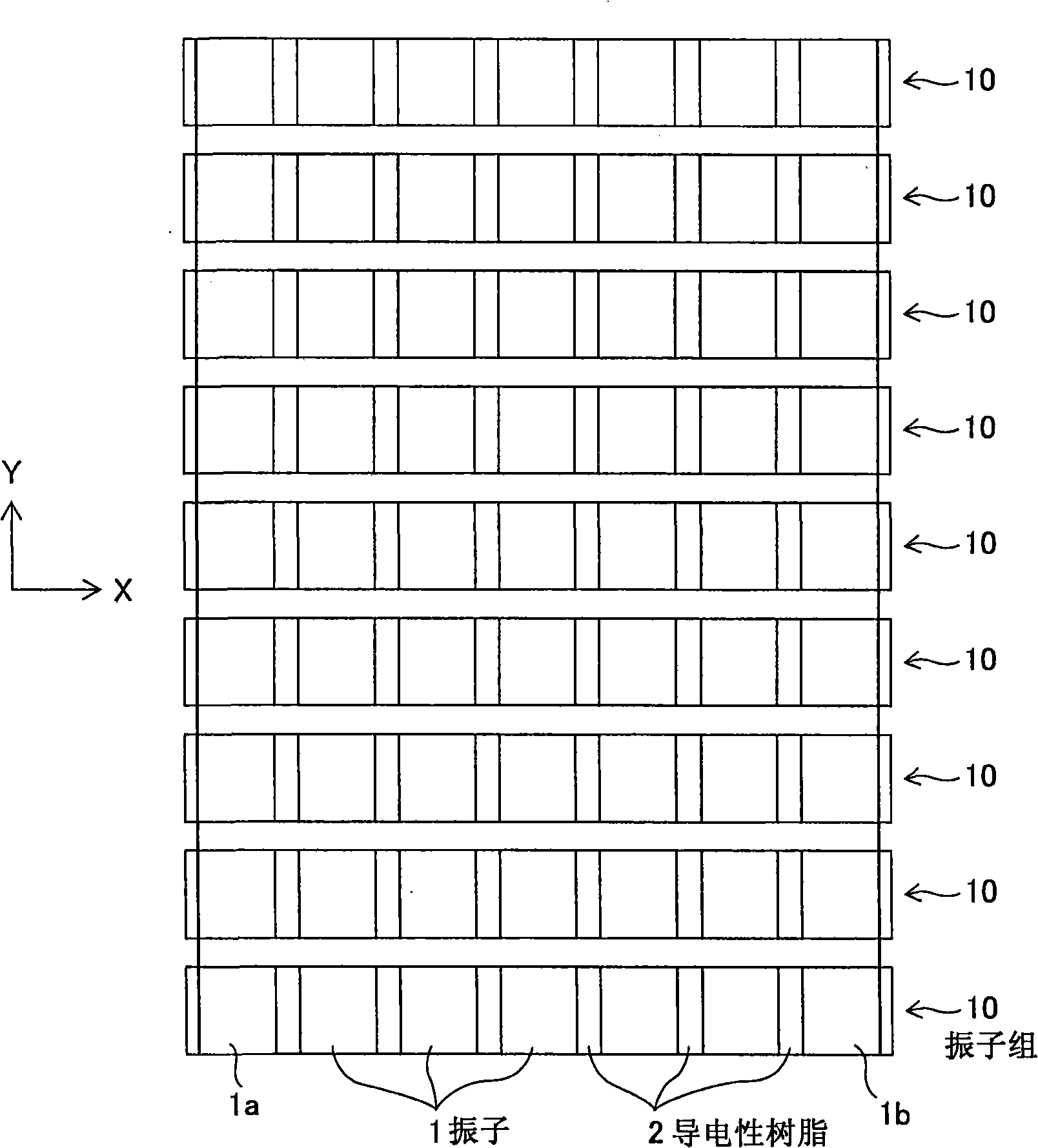

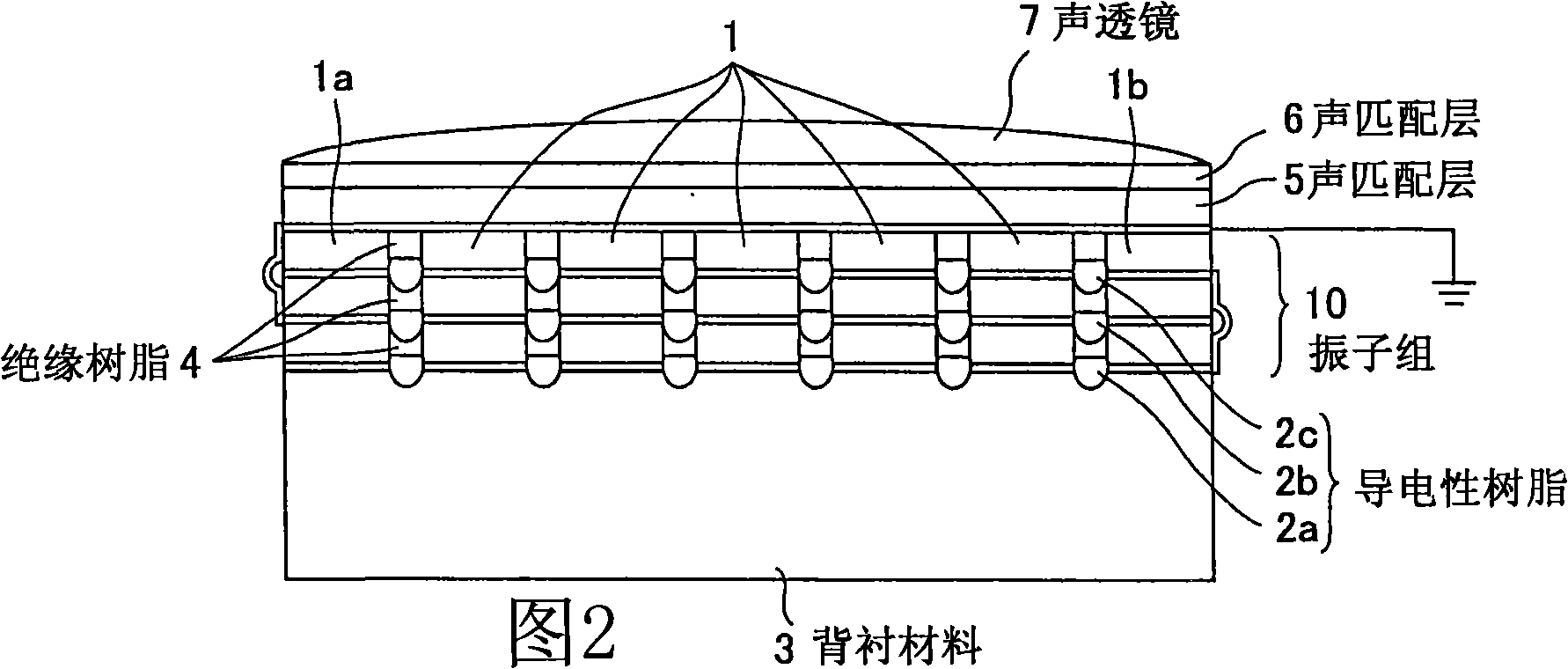

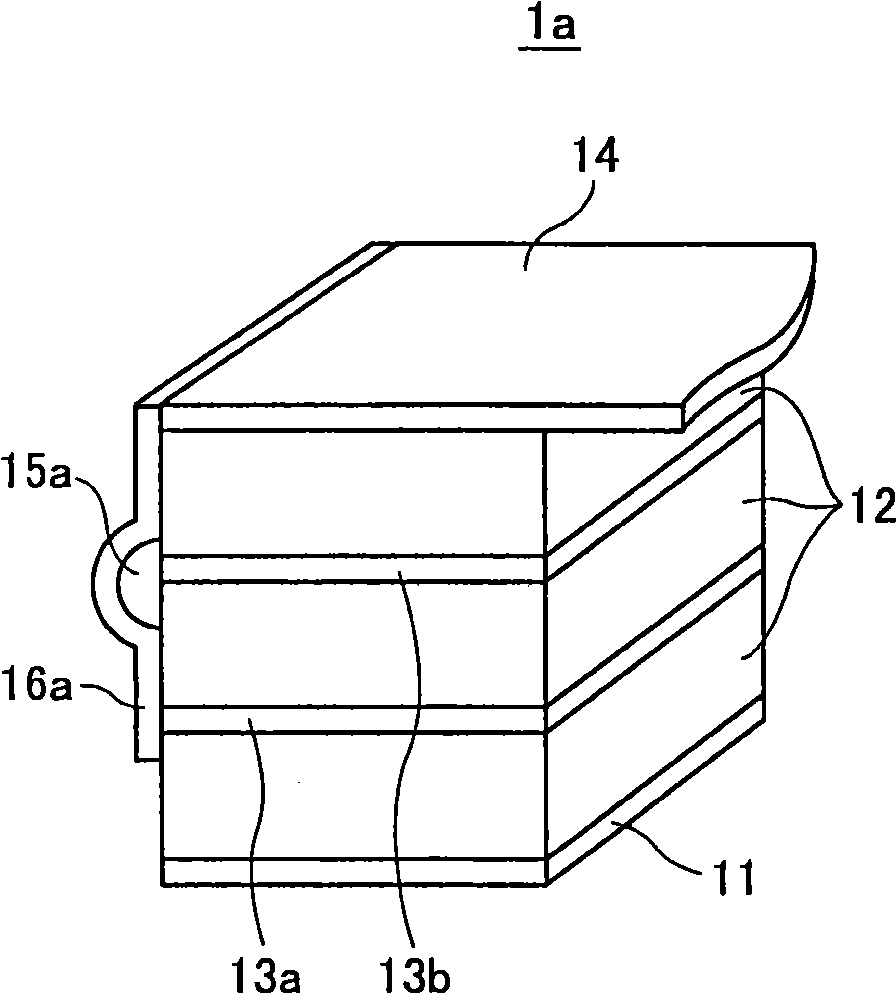

[0034] figure 1 It is a schematic plan view showing an ultrasonic transducer array (transducer array) used in the ultrasonic probe according to the first embodiment of the present invention. This vibrator array includes a plurality of ultrasonic transducers (vibrators) 1 that expand and contract when supplied with a driving signal, transmit ultrasonic waves to a subject to be detected, and output electrical signals (detection signals) by receiving ultrasonic waves reflected by the subject to be detected. . exist figure 1 In the figure, in order to show the arrangement of the vibrators 1 , the upper electrode layer of the vibrators 1 and the insulating resin between the vibrators 1 are omitted. In addition, among the plurality of vibrato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com