Ternary system PSN-PZT piezoelectric ceramic sheet and preparation method thereof

A technology of piezoelectric ceramic sheet and formula, which is applied in the field of piezoelectric ceramic sheet to achieve the effect of simple operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

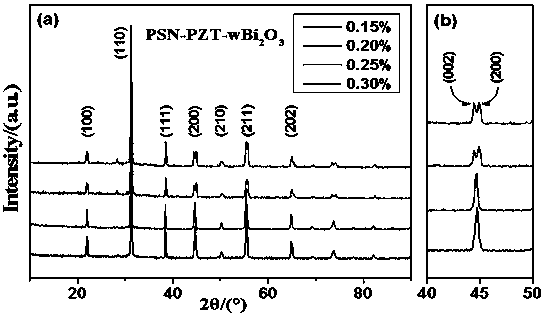

[0041] Embodiment 1, preparation formula stoichiometric general formula is Pb 1-x-y m x Z y (Sb 1 / 3 Nb 2 / 3 ) 0.02 (Zr 1 / 2 Ti 1 / 2 ) 0.98 +zwt%Bi 2 o 3 The ternary system PSN-PZT piezoelectric ceramic sheet; where, x=0.1, y=0.08, z=0.3, M, Z are SrCO 3 、BaCO 3 or CaCO 3 At least two of the The preparation steps are as follows:

[0042] 1) Select raw material Pb 3 o 4 , SrCO 3 、BaCO 3 , ZrO 2 、 Bi 2 o 3 、TiO 2 , Sb 2 o 3 , Nb 2 o 5 Mix with deionized water and ball mill for 4 hours to obtain the first slurry; the speed of the ball mill is 480r / min;

[0043] 2) drying the first slurry at 110-130°C, crushing, and passing through a 40-60 mesh sieve to obtain the first sieve;

[0044] 3) Put the first sieve in the furnace, raise the temperature to 950-1150°C (such as 1000°C) at a rate of 2.5°C / min, keep it warm for 2-4 hours (such as 2 hours), and cool to obtain the pre-fired material;

[0045] 4) Mix the pre-calcined material with deionized water and ball ...

Embodiment 2

[0053] Embodiment 2, preparation formula stoichiometric general formula is Pb 1-x-y m x Z y (Sb 1 / 3 Nb 2 / 3 ) 0.02 (Zr 1 / 2 Ti 1 / 2 ) 0.98 +zwt%Bi 2 o 3 The ternary system PSN-PZT piezoelectric ceramic sheet; where, x=0.15, y=0.03, z=0.2, M, Z are SrCO 3 、BaCO 3 or CaCO 3 At least two of the

[0054] Each preparation step is with embodiment 1. Among them, the pre-sintering temperature in step 3) is 1100°C and the holding time is 2h; the debinding temperature in step 7) is 450°C and the debinding time is 2h; the sintering temperature in step 8) is 1250°C and the holding time 3h; the curing temperature of silver burning in step 9) is 820°C; the temperature of silicone oil in step 10) is 25°C, the electric field strength is 2.3kV / mm, and the lower polarization time is 30min.

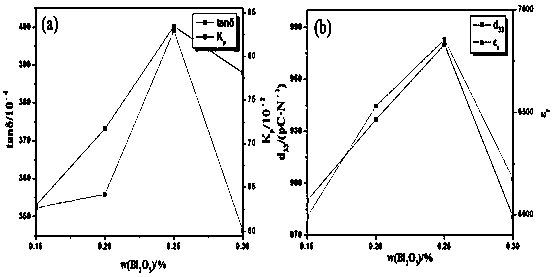

[0055] Test the dielectric constant and piezoelectric constant of the ternary system PSN-PZT piezoelectric ceramic sheet, the test results are shown in figure 1 ; The test results of other elect...

Embodiment 3

[0056] Embodiment 3, preparation formula stoichiometric general formula is Pb 1-x-y m x Z y (Sb 1 / 3 Nb 2 / 3 ) 0.02 (Zr 1 / 2 Ti 1 / 2 ) 0.98 +zwt%Bi 2 o 3 The ternary system PSN-PZT piezoelectric ceramic sheet; where, x=0.13, y=0.05, z=0.25, M, Z are SrCO 3 、BaCO 3 or CaCO 3 At least two of the

[0057] Each preparation step is with embodiment 1. Among them, the pre-sintering temperature in step 3) is 1130°C; the debinding temperature in step 7) is 450°C, and the debinding time is 2h; the sintering temperature in step 8) is 1250°C, and the holding time is 4h; step 10 ), the temperature of the silicone oil in ) is 25°C, the electric field strength is 2.3kV / mm, and the lower polarization time is 30min.

[0058] Test the dielectric constant and piezoelectric constant of the ternary system PSN-PZT piezoelectric ceramic sheet, the test results are shown in figure 1 ; The test results of other electrical performance parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com