Lamb-wave high-frequency resonator

A resonator and Lamb wave technology, applied in the field of Lamb wave high-frequency resonators, can solve problems such as difficult high-frequency band correspondence, phase velocity reduction, and resistance loss increase, so as to reduce manufacturing costs and cut angles Simple, achieve high-frequency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

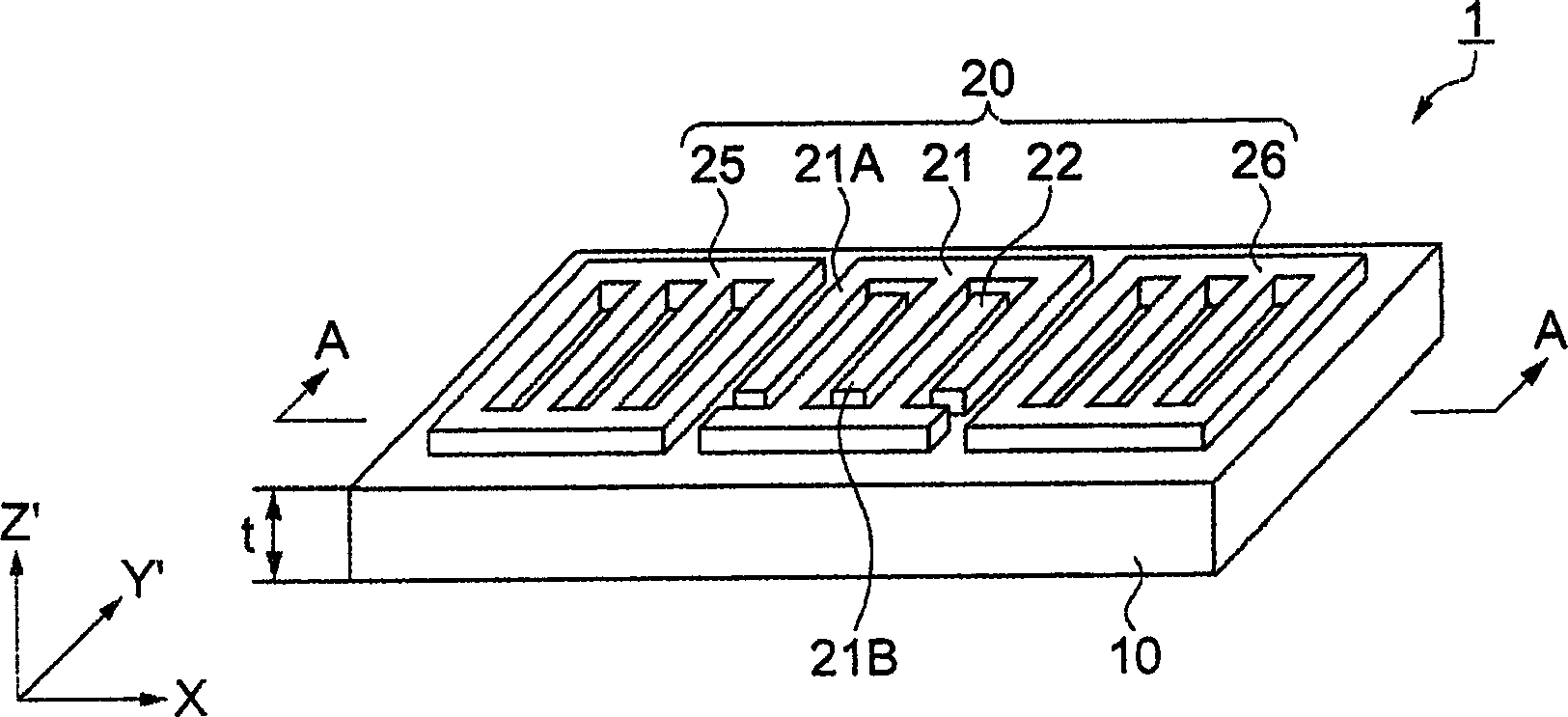

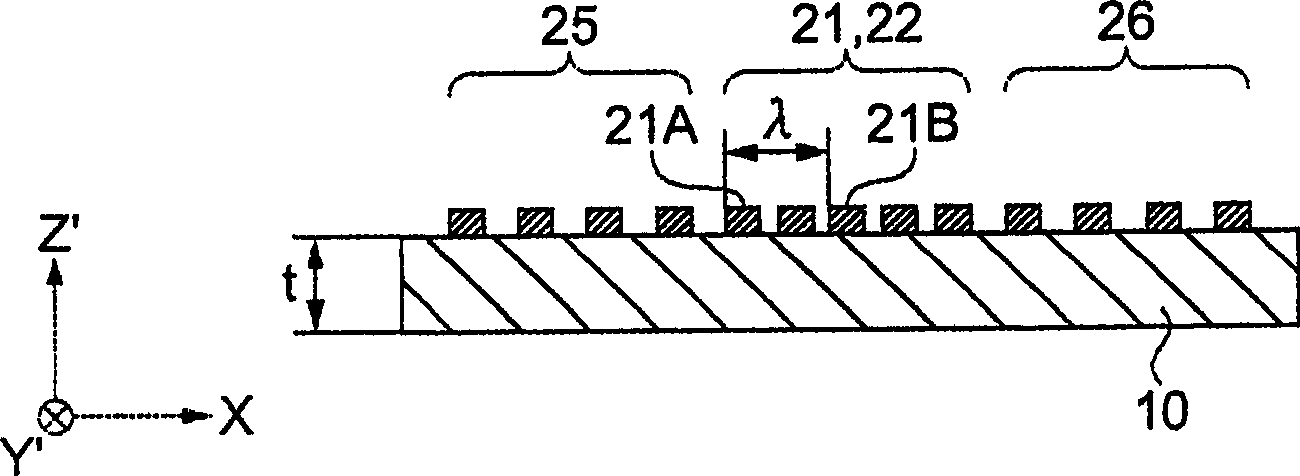

[0064] figure 1 , figure 2 A Lamb wave type high-frequency resonator according to an embodiment of the present invention is shown in . figure 1 It is a perspective view showing a schematic structure, figure 2 is along figure 1 Sectional view of the A-A section. exist figure 1 , figure 2 Among them, this Lamb wave type high-frequency resonator 1 is composed of a quartz substrate 10 and a comb-shaped IDT electrode 20 formed on one main surface of the quartz substrate 10 .

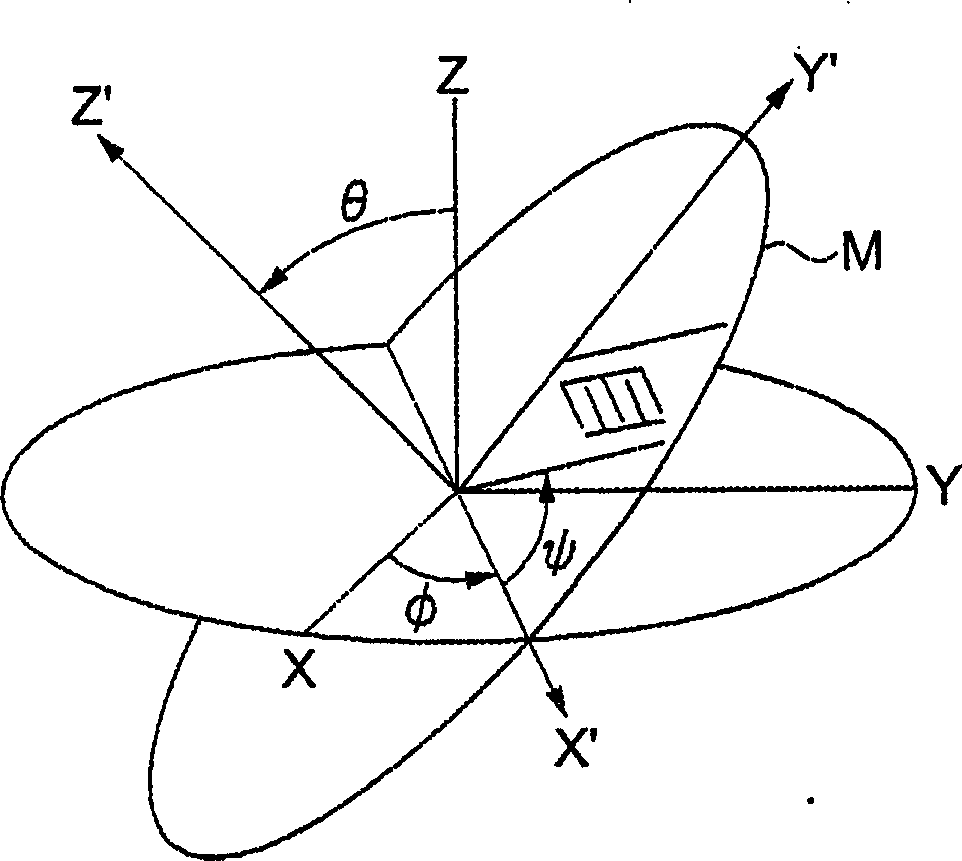

[0065] The cut-off angle of the surface of the quartz substrate 10 and the propagation direction of the Lamb wave are set within a range represented by Euler angles (0, θ, 0). Regarding the thickness t of the quartz substrate 10 , the normalized substrate thickness t / λ is set within a range represented by 0<t / λ≦3 when the wavelength of the propagated Lamb wave is λ.

[0066] The comb-shaped IDT electrode 20 is made of an aluminum electrode, and is formed sequentially on the surface of the quartz sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com