Thin film type structural magnetofluid-sonic surface wave integrated magnetic transducer

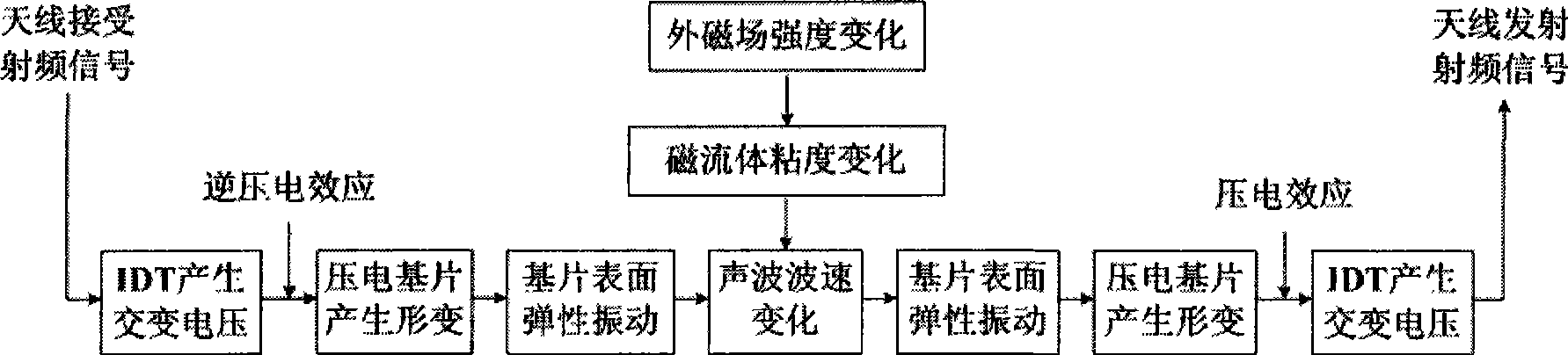

A surface acoustic wave, magnetic sensor technology, applied in the direction of the size/direction of the magnetic field, can solve the problems of the magnetic sensor's response sensitivity is not high enough, the real-time performance is not good enough, it is difficult to realize signal excitation and transceiver control, etc., to achieve a large electromechanical coupling coefficient. , good temperature characteristics, small device effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings:

[0025] This embodiment provides a thin-film magnetic fluid-surface acoustic wave integrated magnetic sensor.

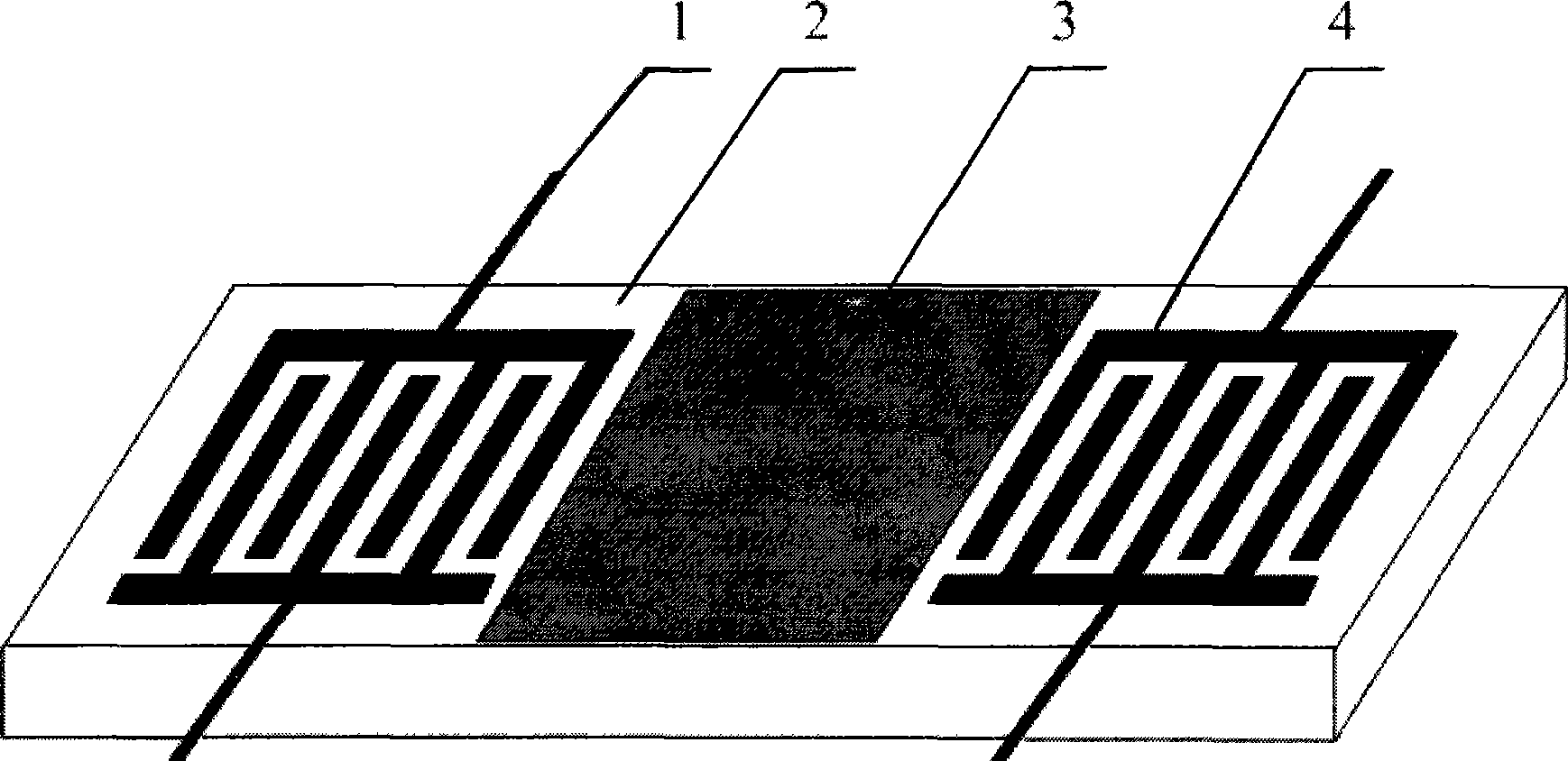

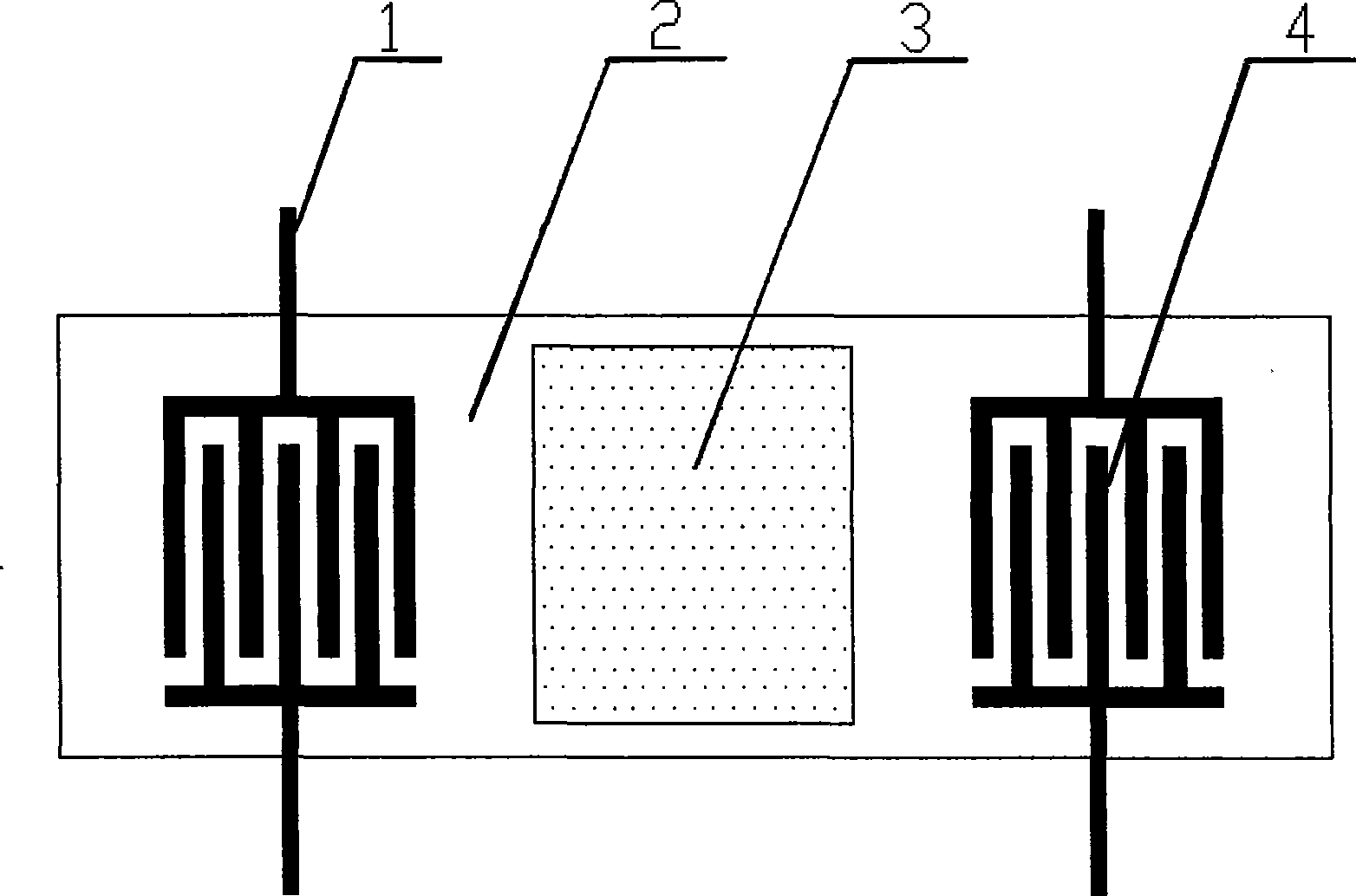

[0026] see figure 1 and figure 2 It is respectively a two-dimensional structure and a top view of a planar structure of a thin-film magnetic fluid-surface acoustic wave integrated magnetic sensor. The sensor includes a piezoelectric substrate 2, two interdigital transducers (IDT) 4, a magnetic fluid thin film 3 and Two sets of antennas 1, wherein two interdigital transducers 4 are respectively located at both ends of the piezoelectric substrate 2, the magnetic fluid film 3 is located in the shallow groove in the middle of the piezoelectric substrate 2 and packaged, and the two sets of antennas 1 are respectively connected to On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com