CMUT (Capacitive Micromachined Ultrasonic Transducer)-based biochemical transducer and manufacturing method thereof

A biochemical sensor, a combined technology, applied in the field of MEMS and biochemistry, can solve the problems of not being able to give full play to the advantages of CMUT, not adapting to biochemical sensors, limiting detection sensitivity and quality limit, etc. Effects of thin film resonance frequency, good mechanical properties and operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

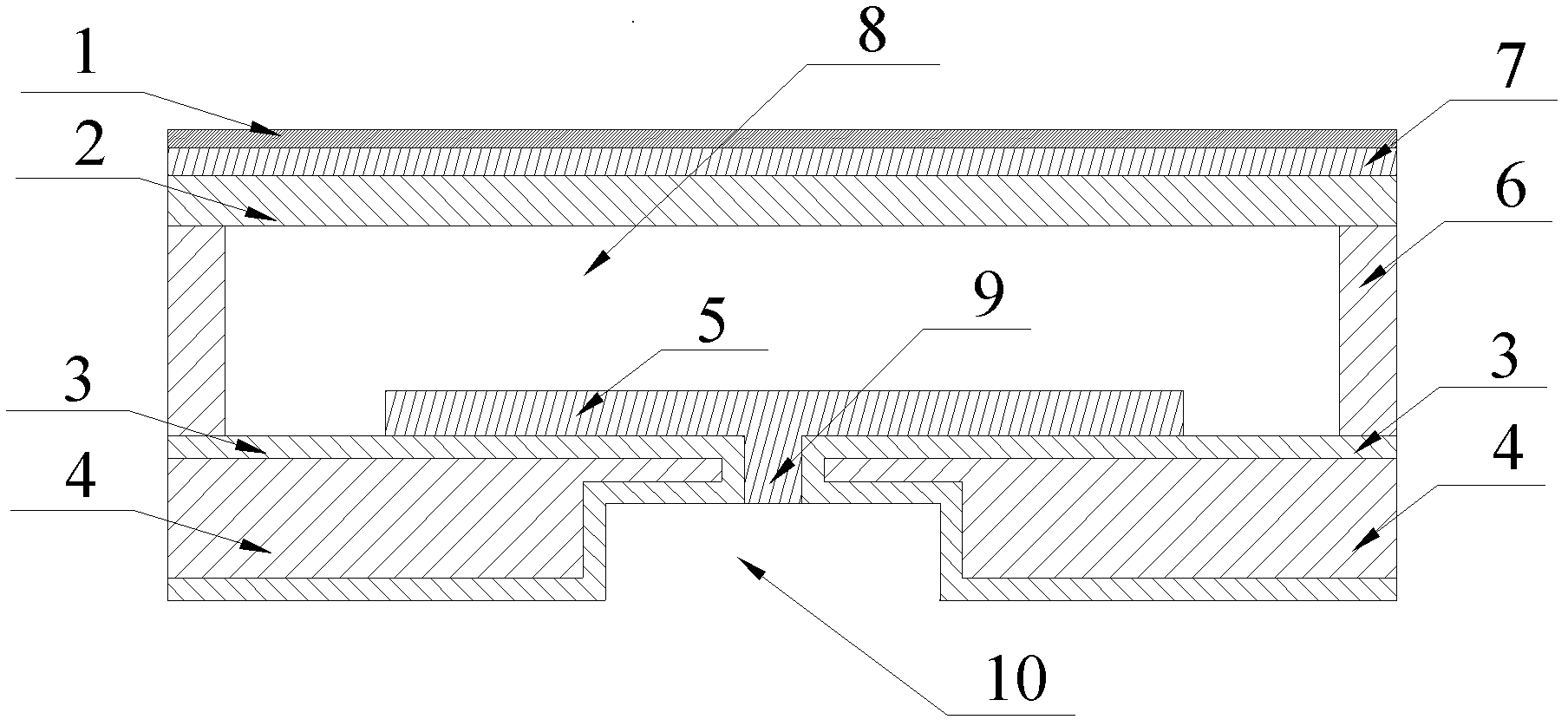

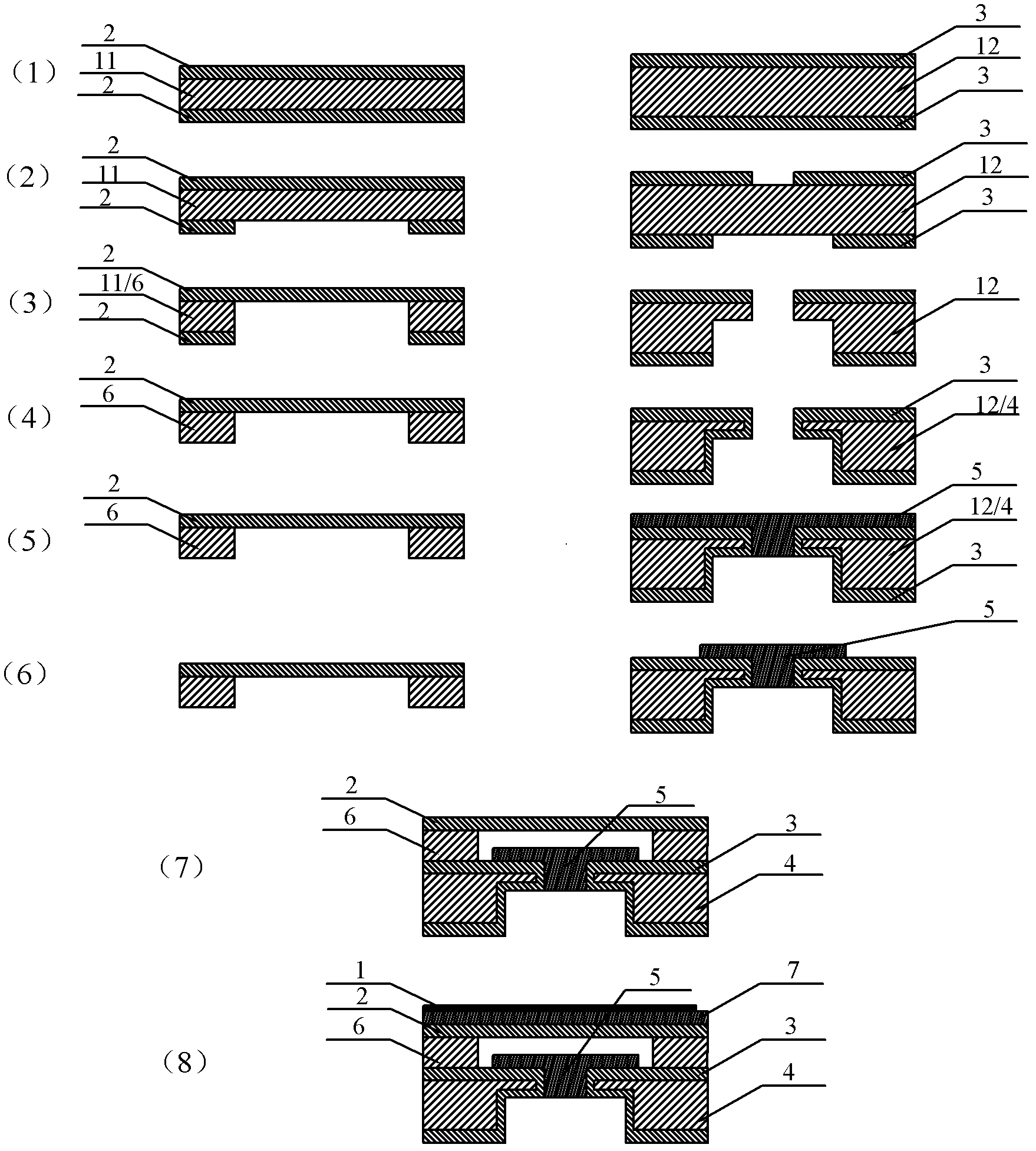

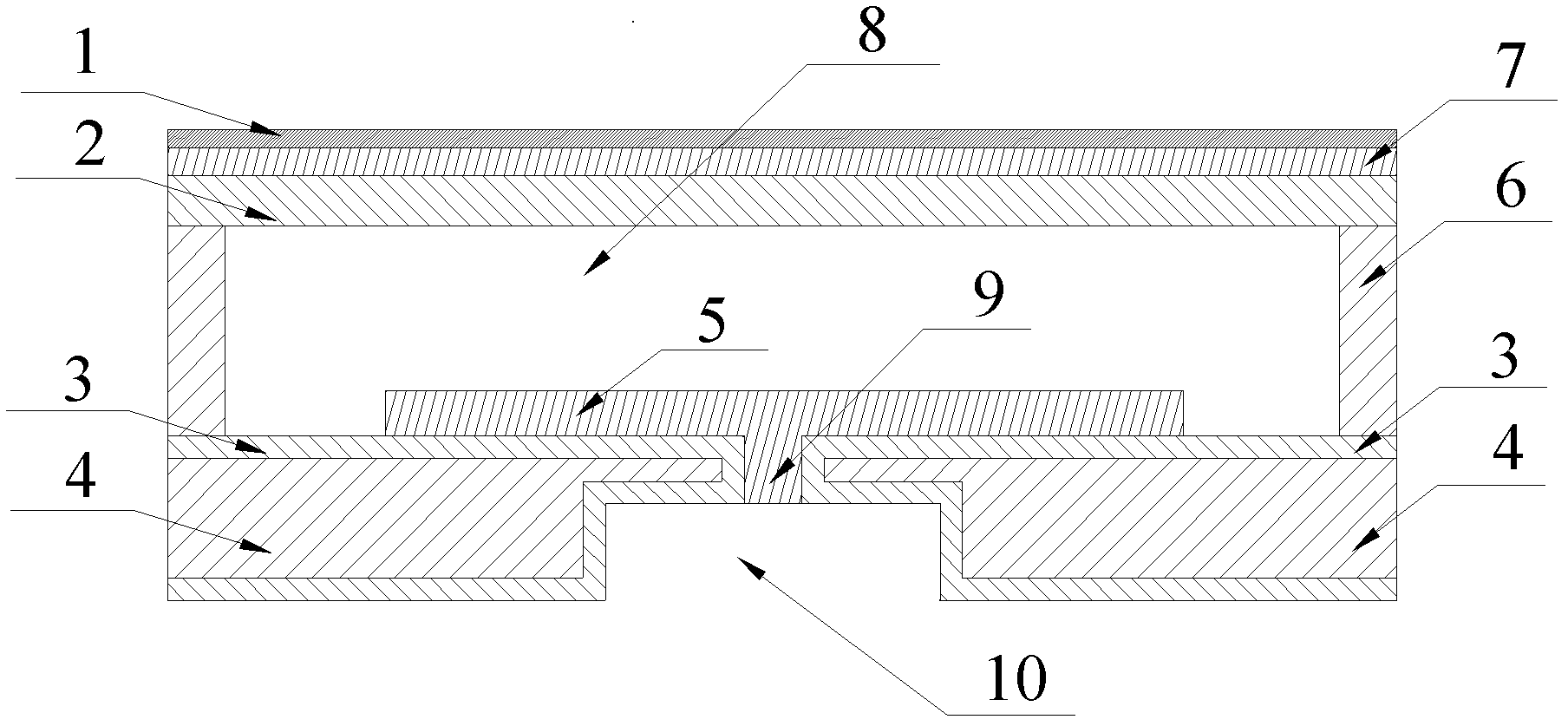

[0029] Below in conjunction with accompanying drawing, the biochemical sensor based on CMUT (Capacitive Micro-fabricated Ultrasonic Transducer) of the present invention and its preparation method are described in detail:

[0030] see figure 1 As shown, the present invention discloses a biochemical sensor based on CMUT, which includes a first part and a second part bonded together up and down. The first component includes the first single crystal silicon, a silicon dioxide film 2 formed by oxidation on the upper surface of the first single crystal silicon, a metal film layer deposited on the upper surface of the silicon dioxide film 2 as the upper electrode 7, deposited on The sensitive identification material layer 1 on the upper surface of the metal thin film layer, wherein a cavity 8 is etched in the middle of the first single crystal silicon, exposing the silicon dioxide film 2, and the remaining first single crystal silicon forms the second part Bonded silicon pillars 6; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com