Composite ignition type combustion light gas gun

A composite ignition type, light gas gun technology, used in compressed air guns, weapons without explosives, weapon types, etc., can solve the problems of rapid reduction of bottom pressure and unsatisfactory launch performance, and achieve excellent performance, simple structure, The effect of increasing the launch speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] Composite ignition type combustion light gas gun of the present invention, its preferred embodiment is:

[0024] It includes the driving section, the driven section, the converging section and the launch tube connected sequentially from back to front, and also includes the ignition control system as an accessory device;

[0025] The driving section is a straight cylindrical structure with a constant circular inner section, its rear end is closed, and its front opening is connected to the driven section;

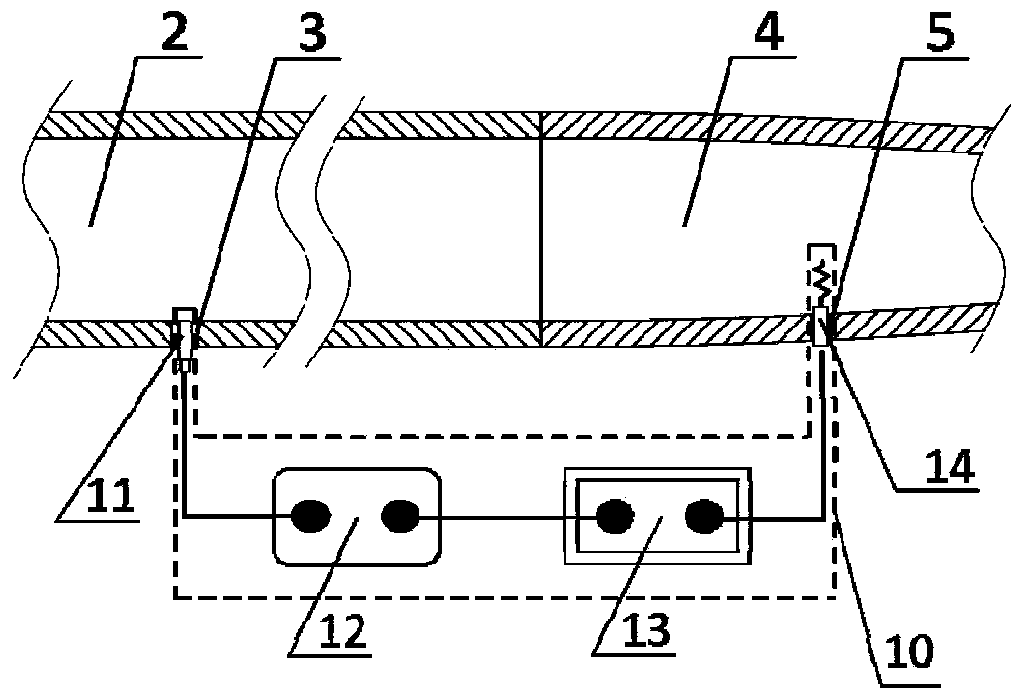

[0026] The driven section is also a straight cylindrical structure with a constant circular inner section, and a diaphragm of the driven section is clamped at the connection with the driving section, and the pipe body of the driven section is provided with a pressure measuring hole;

[0027] The converging section is a cylindrical structure with a circular cross-section, its inner diameter gradually decreases continuously and smoothly from the back to the front, and th...

specific Embodiment

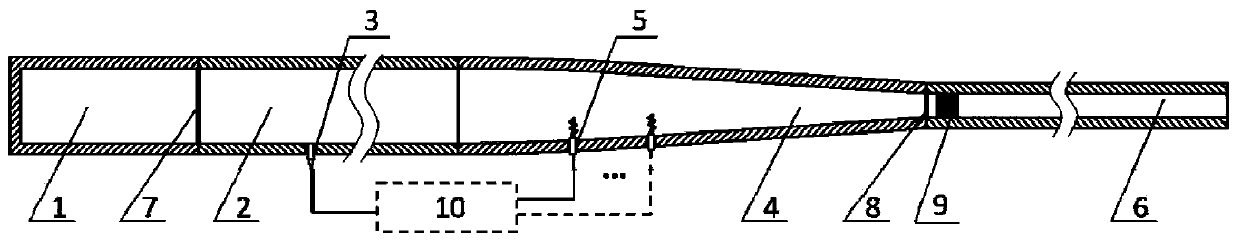

[0046] See attached figure 1 , a compound ignition type combustion light gas gun, which includes: a driving section 1, a driven section 2, a pressure measuring hole 3, a converging section 4, a screw hole 5, a launch tube 6, and is clamped on the driving section 1 and the driven section 2 The driven section diaphragm 7 at the junction, the launch tube diaphragm 8 clamped at the junction of the converging section 4 and the launch tube 6, the projectile 9, and the ignition control system 10.

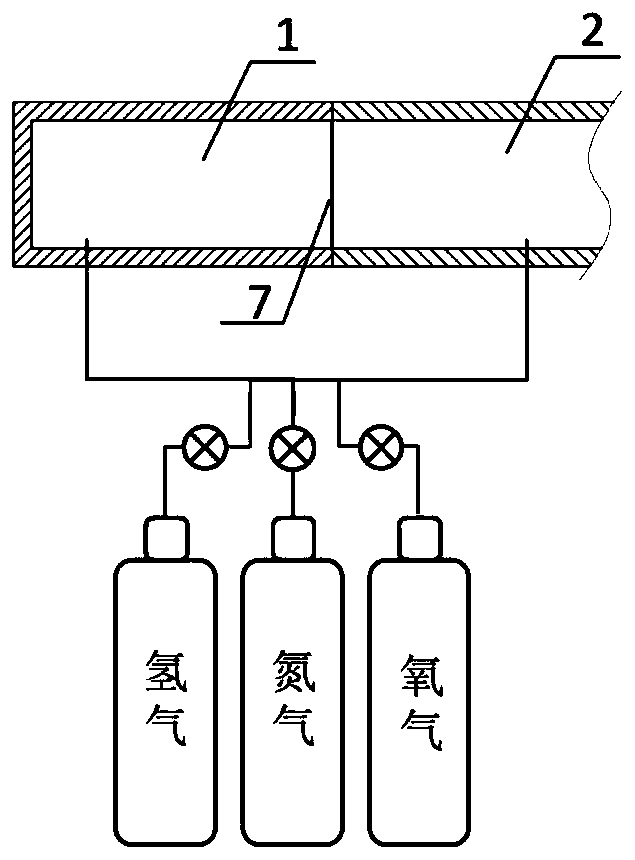

[0047] The driving section 1 is a straight cylindrical structure with a constant circular inner section, its rear end is closed and its front end is open; the driving section 1 is pre-filled with a certain proportion of hydrogen and nitrogen compressed gas.

[0048] The driven section 2 is a straight cylindrical structure with a constant circular inner section, one end is connected to the driving section 1, the driven section diaphragm 7 is clamped at the connection, and the other end is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com