Clearance type sealing Stirling thermoelectric converter supported by adopting supporting flexible plate springs

A leaf spring, gap technology, applied in the field of gap seal Stirling thermoelectric converters, achieves great advantages, low friction loss and hysteresis loss, and meets the stiffness requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

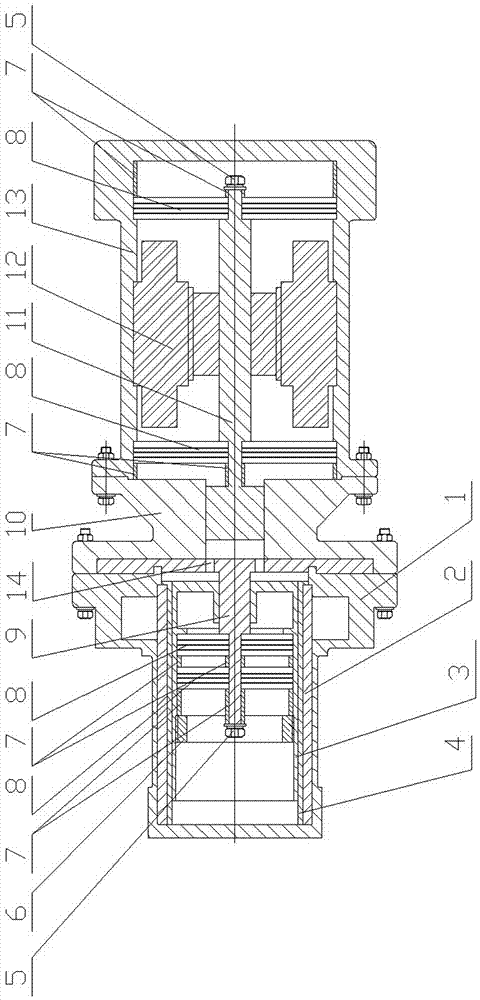

[0015] The present invention and its beneficial effects will be further described in detail with reference to the accompanying drawings.

[0016] like figure 1 As shown, the thermal cylinder 1 is located at the left end, the compression cylinder 10 is located at the middle, and the generator 12 is located at the right end, and the three are fixed together by flanges. The thermal cylinder 1, the heat exchanger 2, the expansion cylinder 4, and the expansion piston 3 are long cylinders, which are sequentially fitted together inwardly; the expansion piston 3 is installed on the expansion piston rod 9 located on the central axis of the thermal cylinder 1. There are two sets of supporting flexible plate springs 8 in the expansion piston 3, which are respectively placed at the two ends of the expansion piston rod 9; the outer diameter of the supporting flexible plate springs 8 is closely matched with the inner wall of the expansion piston 3, and its central hole is sleeved on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com