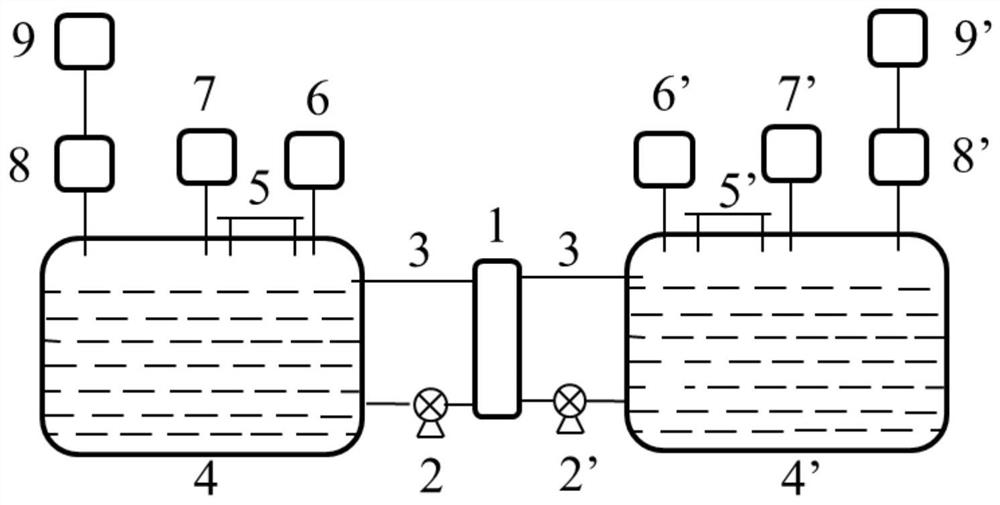

Universal device for reducing electrolyte migration of flow battery

A liquid flow battery and electrolyte technology, applied in fuel cells, electrolyte flow processing, fuel cell additives, etc., can solve problems such as positive and negative electrolyte valence imbalance, electrolyte migration, etc., to solve capacity decay and easy operation , long-term operation and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Taking the all-vanadium redox flow battery system as an example, assemble a 10-cell stack, in which the electrode is carbon felt, the electrode area is 1000cm2, the diaphragm is Nafion115, the volume of the positive and negative electrolytes is 30L, and the volumes of the positive and negative storage tanks are respectively 50L. Through the gas pressure regulator, the pressure in the positive storage tank is increased to 0.12MPa, the pressure in the negative storage tank is maintained at normal atmospheric pressure, the battery voltage window is 10V-15.5V, and the stack is charged and discharged at 100mA / cm2, and the cycle is 100 times Afterwards, the volume of the positive electrode electrolyte becomes 31L, the volume of the negative electrode electrolyte becomes 29L, and the battery capacity decays by 20%.

Embodiment 2

[0029] Taking the all-vanadium redox flow battery system as an example, assemble a 10-cell stack, in which the electrode is carbon felt, the electrode area is 1000cm2, the diaphragm is Nafion115, the volume of the positive and negative electrolytes is 30L, and the volumes of the positive and negative storage tanks are respectively 50L. Through the gas pressure regulator, the pressure in the negative storage tank is reduced to 0.8 atmospheric pressure, the pressure in the positive storage tank is maintained at normal atmospheric pressure, the battery voltage window is 10V-15.5V, and the stack is charged and discharged at 100mA / cm2, and the cycle is 100 times After that, the positive electrode electrolyte volume becomes 31.1L, the negative electrode electrolyte volume becomes 28.9L, and the battery capacity decays by 21%.

Embodiment 3

[0033] Taking the zinc-iron flow battery system as an example, assemble a 10-cell stack, in which the electrodes are carbon felts, the electrode area is 1000cm2, the diaphragm is PBI ion exchange membrane, the positive and negative electrolyte volumes are 30L, and the positive and negative storage tanks are The volume is 60L respectively. Through the gas pressure regulator, increase the pressure in the negative storage tank to 0.15MPa, keep the pressure in the positive storage tank at normal atmospheric pressure, charge the stack at 40mA / cm2 for 1h, discharge the stack at 40mA / cm2 for 1h, and cycle 50 times Afterwards, the volume of the positive electrode electrolyte solution becomes 25L, and the volume of the negative electrode electrolyte solution becomes 35L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com