1000MW stage secondary reheating unit single-row high-pressure heater system

A high-pressure heater and secondary reheating technology, which is applied to feed water heaters, lighting and heating equipment, preheating, etc., can solve the high risk of high-pressure heater removal, steam coolers that cannot be operated on one side, and failure points Increase and other problems, to achieve the effect of simple thermal measuring points and control, small resistance, and reduced pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

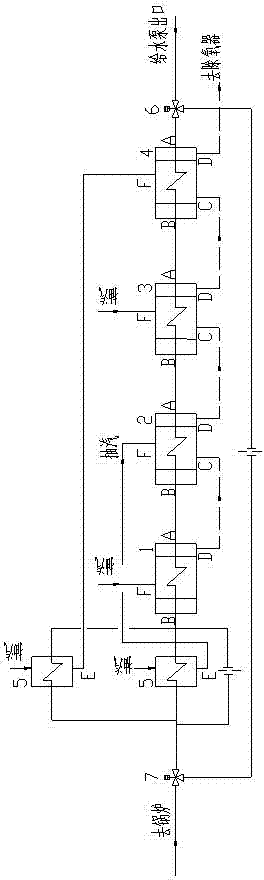

[0013] Such as figure 1 As shown, a single-row high-pressure heater system of a 1000MW double reheat unit includes four high-pressure heaters connected in series through the water supply pipeline, and the drain ports of the high-pressure heaters are connected in series.

[0014] The four high-pressure heaters are respectively the first to fourth high-pressure heaters 1 to 4, the feedwater inlet A of the fourth high-pressure heater 4 is connected to the outlet of the feedwater pump through the feedwater pipeline, and the feedwater outlet B is connected to the third high-pressure heater 3 is connected to the feed water inlet A, the feed water outlet B of the third high pressure heater 3 is connected to the feed water inlet A of the second high pressure heater 2, and the feed water outlet B of the second high pressure heater 2 is connected to the feed water inlet of the first high pressure heater 1 A connection, the feed water outlet B of the first high pressure heater 1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com