New process for treating sewerage

A sewage treatment and new process technology, applied in the direction of water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Poor processing capacity and other issues, to achieve the effect of improving processing capacity and processing efficiency, reducing investment and operating costs, and changing the sewage treatment path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

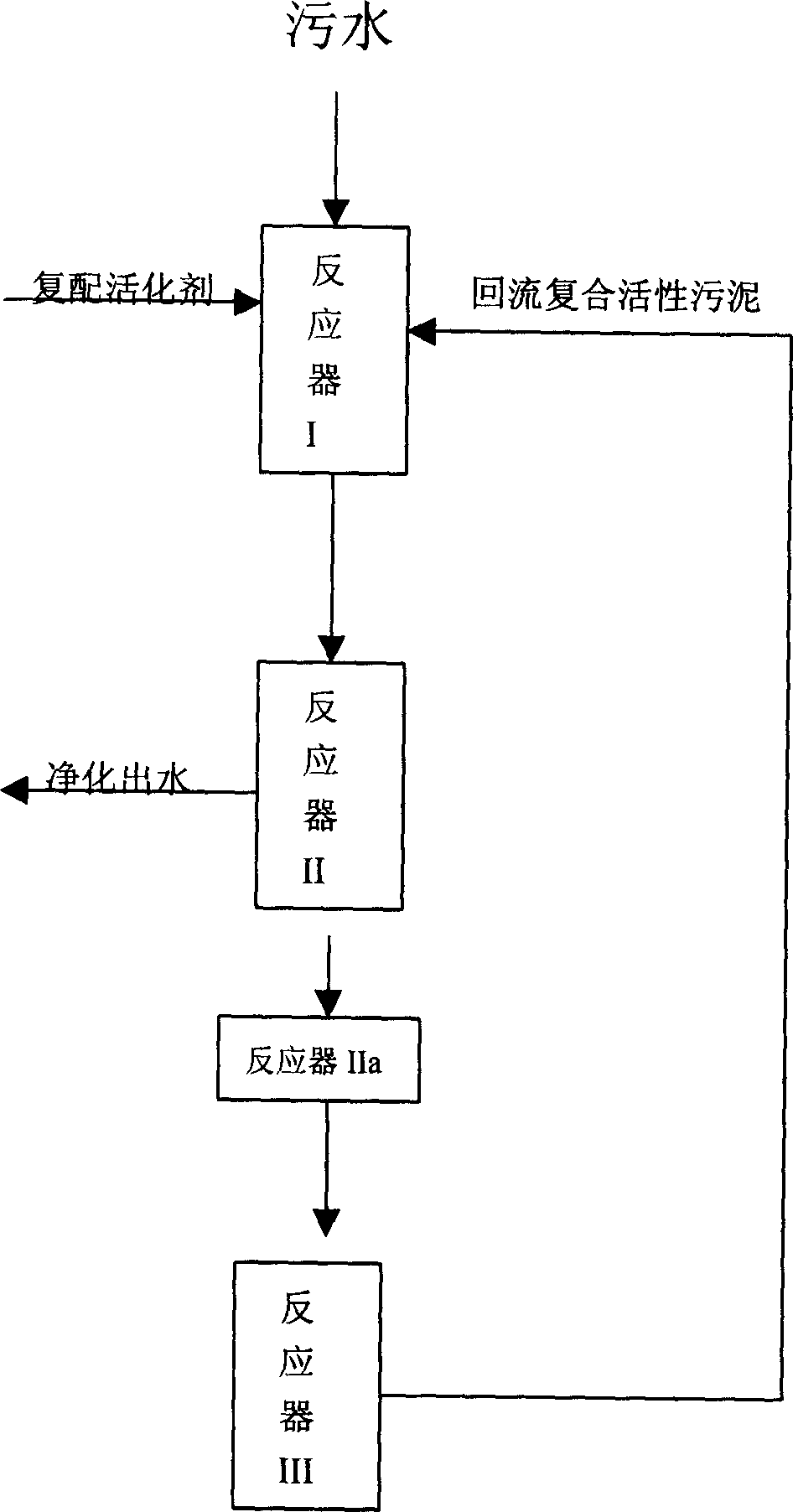

[0011] Add a compound activator whose main component is iron or carbon to the reactor I. The compound activator combines with the activated sludge in the process to form a compound activated sludge. The compound activated sludge has the functions of absorption, adsorption and flocculation of pollutants. The biological, chemical and physical functions can realize the phase transfer of pollutants; the sewage flows into the reactor I to mix with the composite activated sludge, and then enters the reactor II to separate the pollutants from the sewage, and the purified sewage is discharged and separated After the discharged sludge enters the reactor IIa, one path is fully degraded by the reactor III and then returned to the reactor I for recycling, and the other path is discharged. In order to reduce the burden on the reactor IIa, some sludge can also be discharged before the reactor IIa according to the process requirements. The above-mentioned reactors can also be regarded as sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com