Passive molten salt thermal absorber

A salt heat absorber and molten salt technology, applied in indirect heat exchangers, heat exchanger types, solar collectors, etc., can solve problems such as pump power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

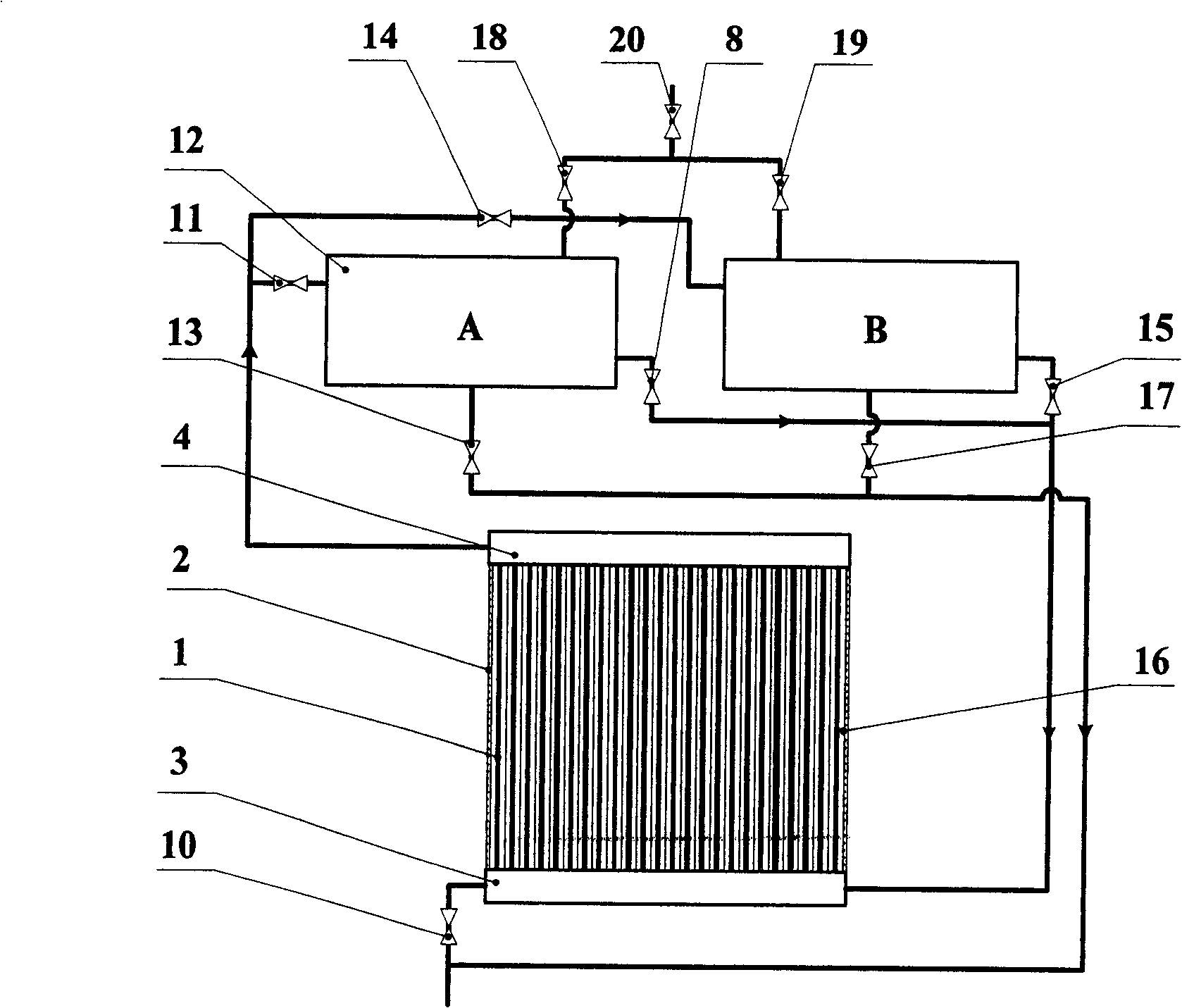

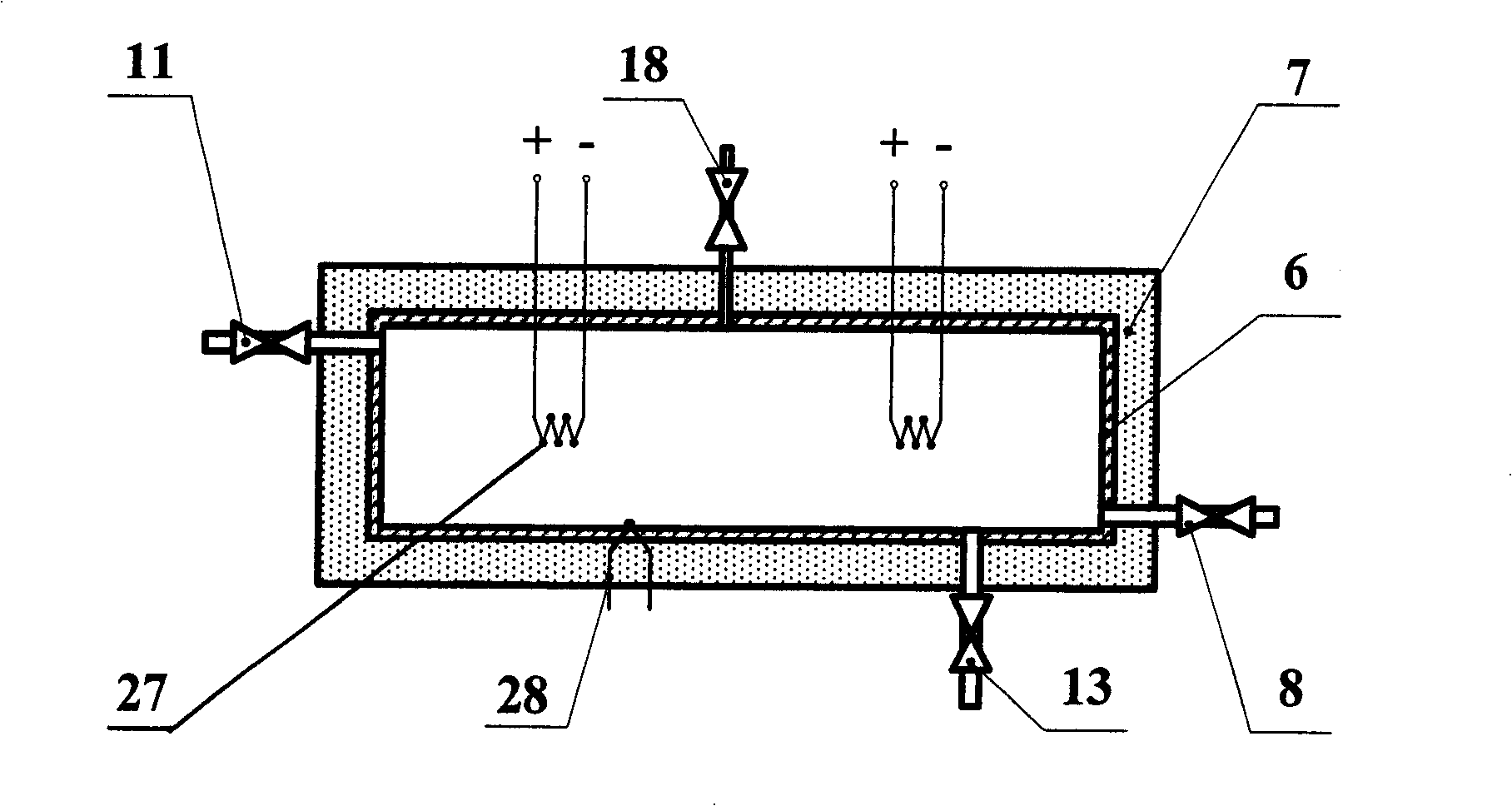

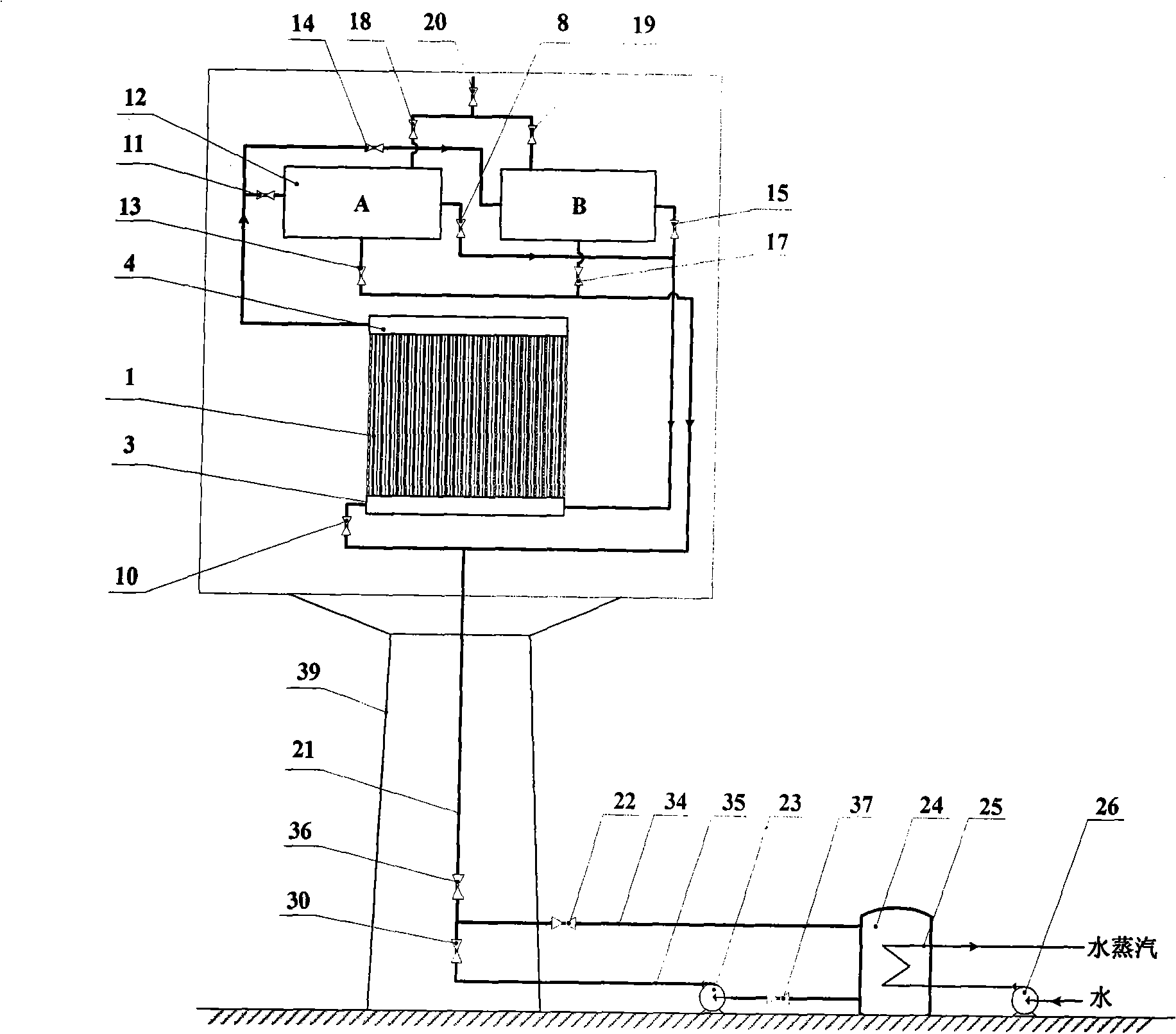

[0014] figure 1 It is a structural schematic diagram of the heat absorber of the present invention. Such as figure 1 As shown, the heat absorber of the present invention includes heat absorbing pipe 1, heat-resistant insulation board 2, high temperature molten salt tank 12, upper header pipe 4, lower header pipe 3 and other components. The outer surface of the heat-absorbing pipe 1 is equipped with fins 16, and has a high-temperature-resistant solar selective absorption coating, and a plurality of heat-absorbing pipes 1 are connected in series or in parallel to form a heat-absorbing surface. The heat-absorbing surface faces the heliostat field, and a heat-resistant insulation board 2 is installed behind the heat-absorbing surface. The upper part of the heat-absorbing pipe 1 is an upper header pipe 4, and the upper header pipe 4 is connected with the high-temperature molten salt tank 12 by the riser pipe 5. The lower part of the heat-absorbing pipe 1 is the lower header pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com