Control system of injection molding machine

A control system and injection molding machine technology, applied in the field of injection molding machines, can solve the problems of restricting the performance of injection molding machines, reducing machine performance, and not having multiple pressure sensor signal feedback processing systems, so as to fully exert the ability of high servo response and improve accuracy The effect of effectively improving the performance and stability of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below in conjunction with specific embodiments.

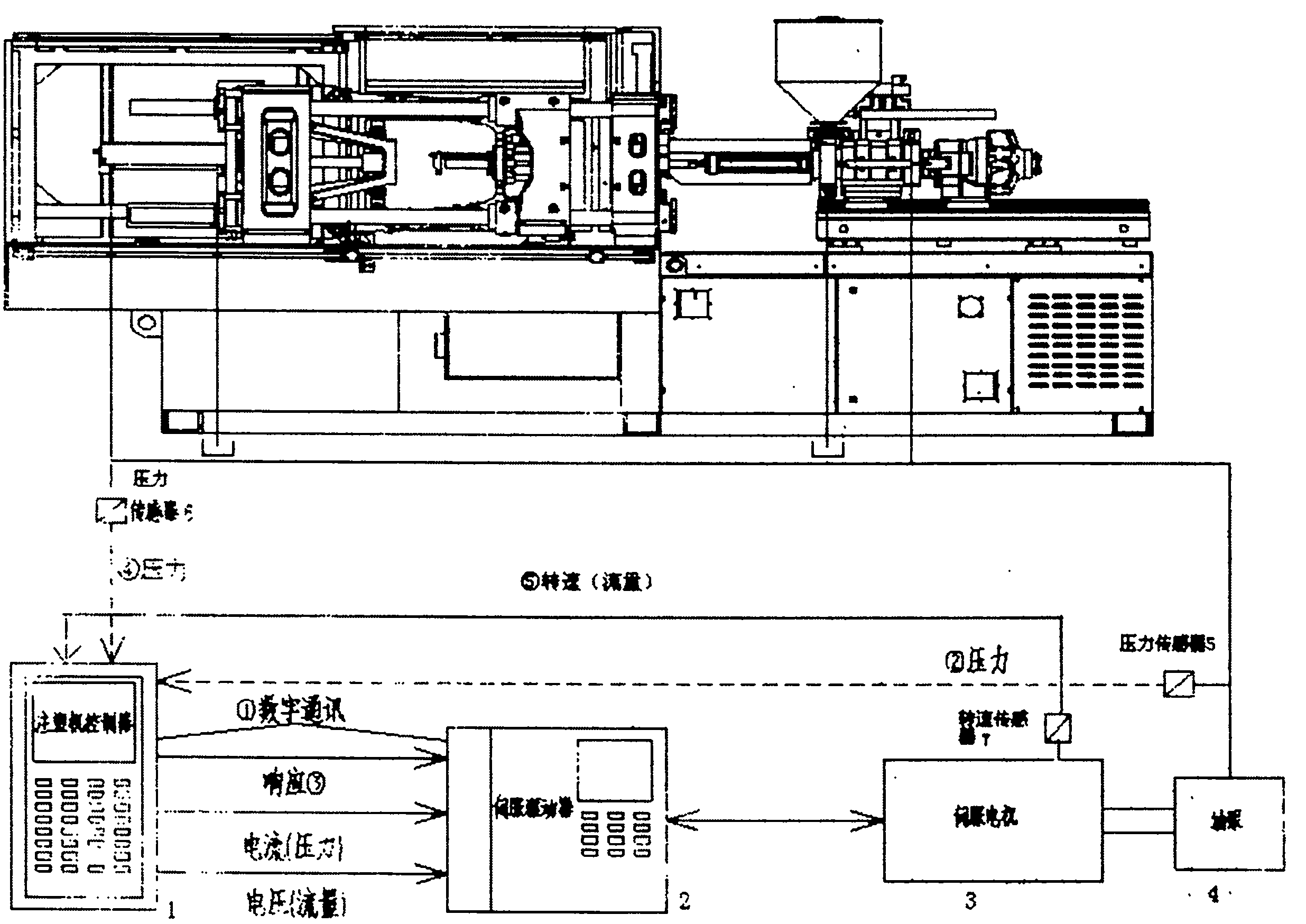

[0026] The injection molding machine is controlled by the man-machine interface---injection molding machine controller to control all actions. The action control process of the injection molding machine is basically the same. All actions are composed of injection, mold opening and closing, ejection, plasticization, and seat advance and retreat. The main actions are injection and mold opening and closing. These two actions have the greatest impact on machine performance.

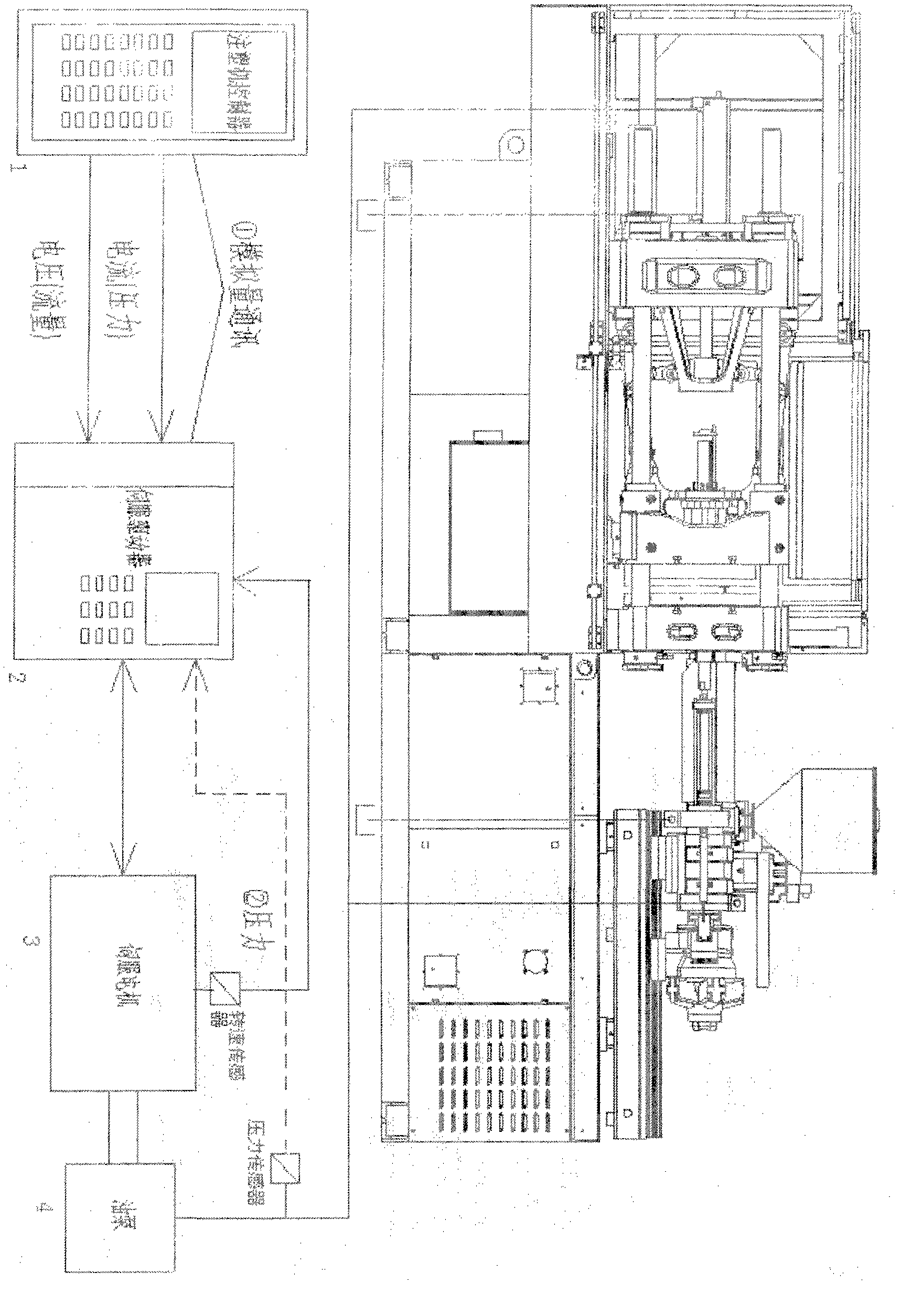

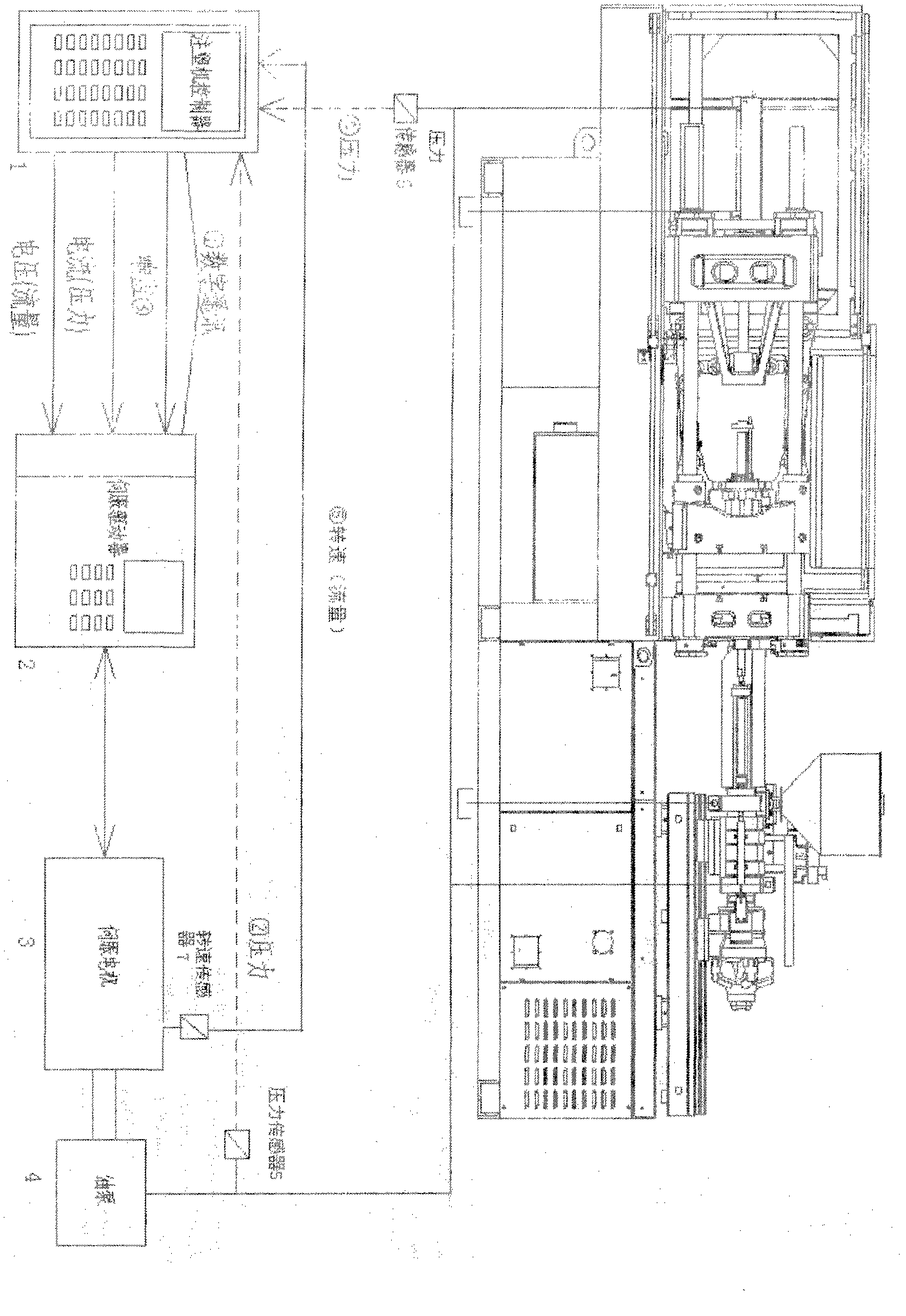

[0027] Such as figure 2Said, an injection molding machine control system, including an injection molding machine controller 1, a servo driver 2, a servo motor 3, a quantitative oil pump 4 for providing pressure to the hydraulic system, pressure sensors (5, 6), and a rotational speed sensor 7, wherein the injection molding machine The controller 1 is connected to the servo driver 2 and sends an action command ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com