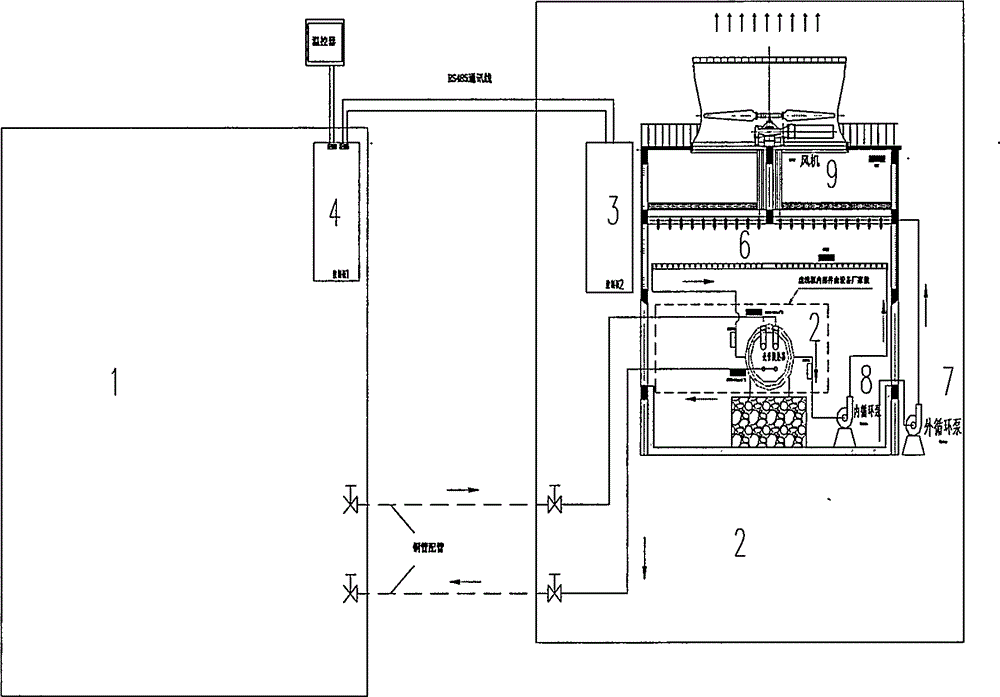

Split type water source heat pump system

A water source heat pump, split technology, applied in the field of water source heat pump systems, can solve the problems of too long pipelines, many interfaces, difficult to control antifreeze, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] There are two modes:

[0012] In cooling mode, the heat pump host sends cooling demand and start-up signals to the closed cooling tower control module through the host control module, and the latter controls the external circulation pump, internal circulation pump and fan of the closed cooling tower to start. The function of the cooling tower, that is, the spray cooling function, cools the water in the air-cooled coil heat exchanger, and then cools the water in the water-refrigerant condenser through the built-in circulation pump, thereby cooling the latter's refrigerant.

[0013] In heating mode, the heat pump host sends heating demand and start-up signals to the closed cooling tower control module through the host control module, and the latter controls the internal circulation pump and fan of the closed cooling tower to start. The cooling tower fan exchanges heat with the air-cooled coil heat exchanger and heats the water-ethylene glycol solution in it, and then heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com