Process for synthesizing MCM-56 molecular sieve

A technology of MCM-56 and synthesis method, which is applied in the field of synthesis of MCM-56 molecular sieve, can solve the problems such as difficult control of MCM-56 molecular sieve crystal phase and easy occurrence of crystal transformation, so as to solve the problem that crystal phase is difficult to control, the process is simple and easy The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The raw material MCM-22(p) was synthesized according to the method described in US 4,954,325.

[0021] The first step acid treatment MCM-22(p)

[0022] MCM-22(p) and a nitric acid solution with a concentration of 2 mol / l were prepared in a weight ratio of 1:50 to prepare a reaction mixture, treated at room temperature for 20 hours, filtered, washed, and dried to obtain an acid-treated product;

[0023] Second step roasting

[0024] The acid-treated product obtained in the first step was calcined at 550°C for 8 hours to obtain the product MCM-56 molecular sieve.

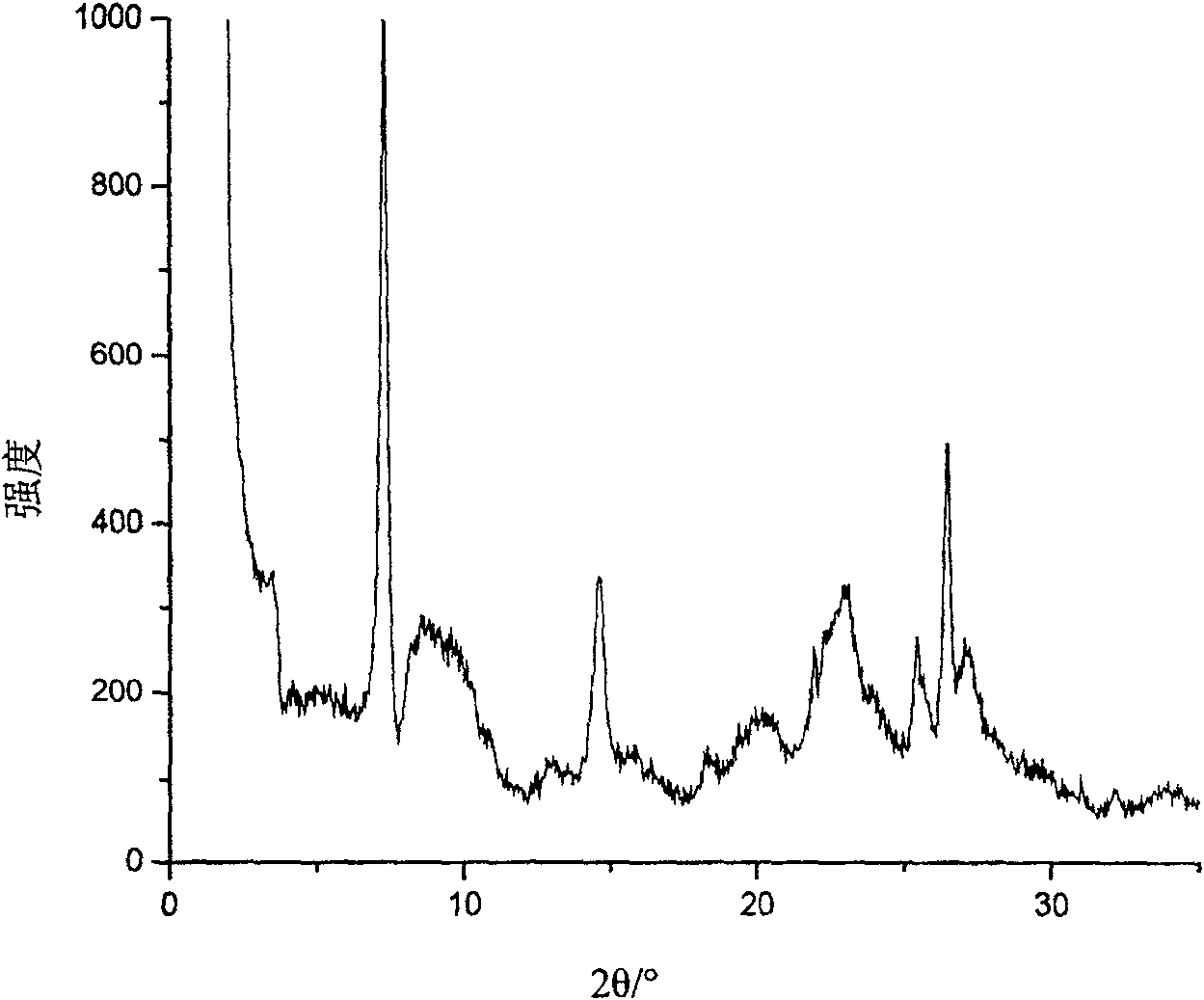

[0025] The XRD spectrum of the product MCM-56 molecular sieve is as follows figure 1 shown.

Embodiment 2~6

[0027] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0028] The first step acid treatment MCM-22(p)

[0029] Reaction mixture weight ratio and processing conditions:

Embodiment 2

[0030] Embodiment 2MCM-22 (p): 6mol / l nitric acid=1: 20, treated at room temperature for 36 hours;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com