Welding method of nuclear power steam generator

A technology of steam generator and welding method, applied in welding equipment, laser welding equipment, metal processing equipment, etc., to achieve the effects of easy guidance, stable and reliable processing quality, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

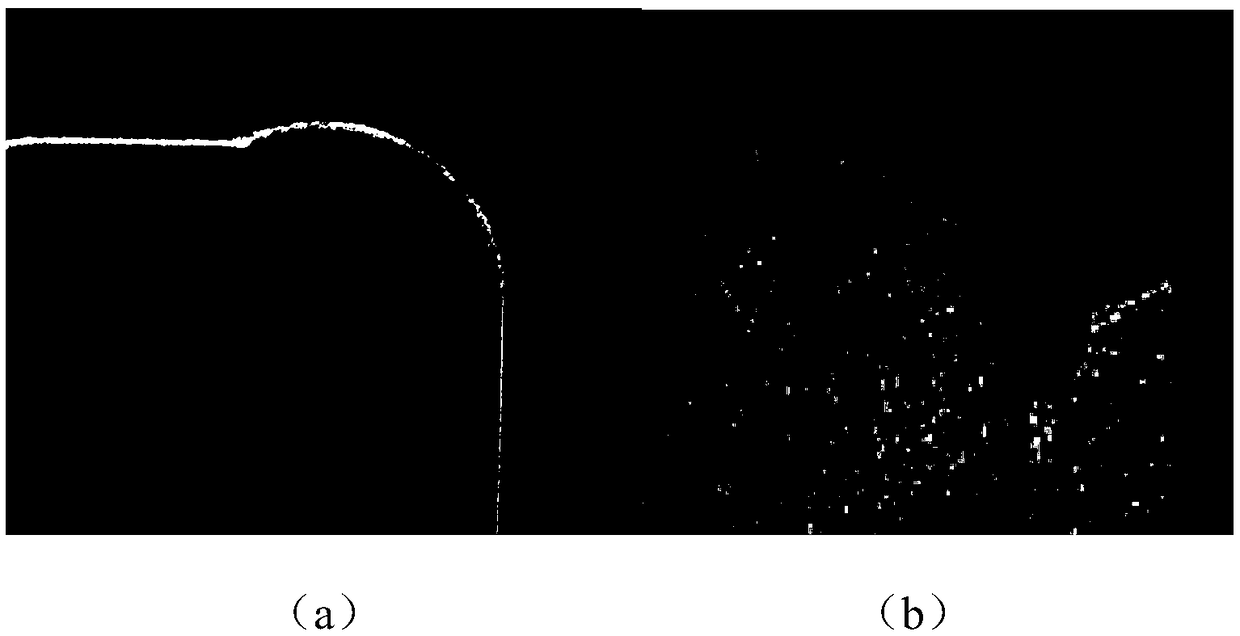

[0018] The invention uses laser welding instead of argon arc welding to weld the tube plate of the nuclear power steam generator. The example tube is a 690 nickel-based tube, and the material of the tube plate is low-alloy steel, and the nickel-based surfacing layer formed by laser welding is used to fix the connection between the two. The example tube-to-tubesheet joint form is flush.

[0019] The laser energy density is high, and there is a pinhole effect in the welding process, that is, the laser with high power density is incident on the surface of the workpiece, causing the surface temperature of the workpiece to rise rapidly, melt, and vaporize, and form a hole inside the workpiece under the action of vaporization expansion pressure. A small hole around which a molten pool is formed. Therefore, the weld depth-to-width ratio of laser welding is large, which can significantly increase the penetration depth.

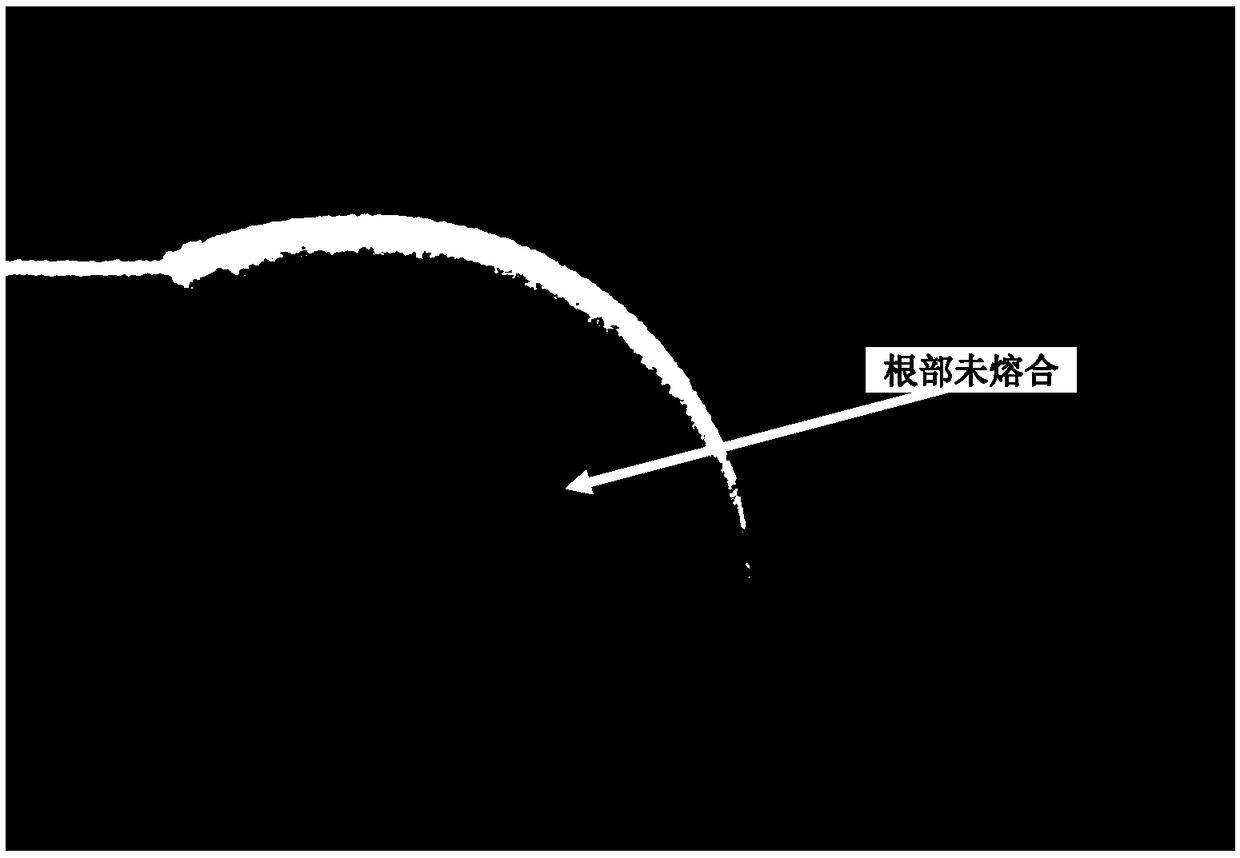

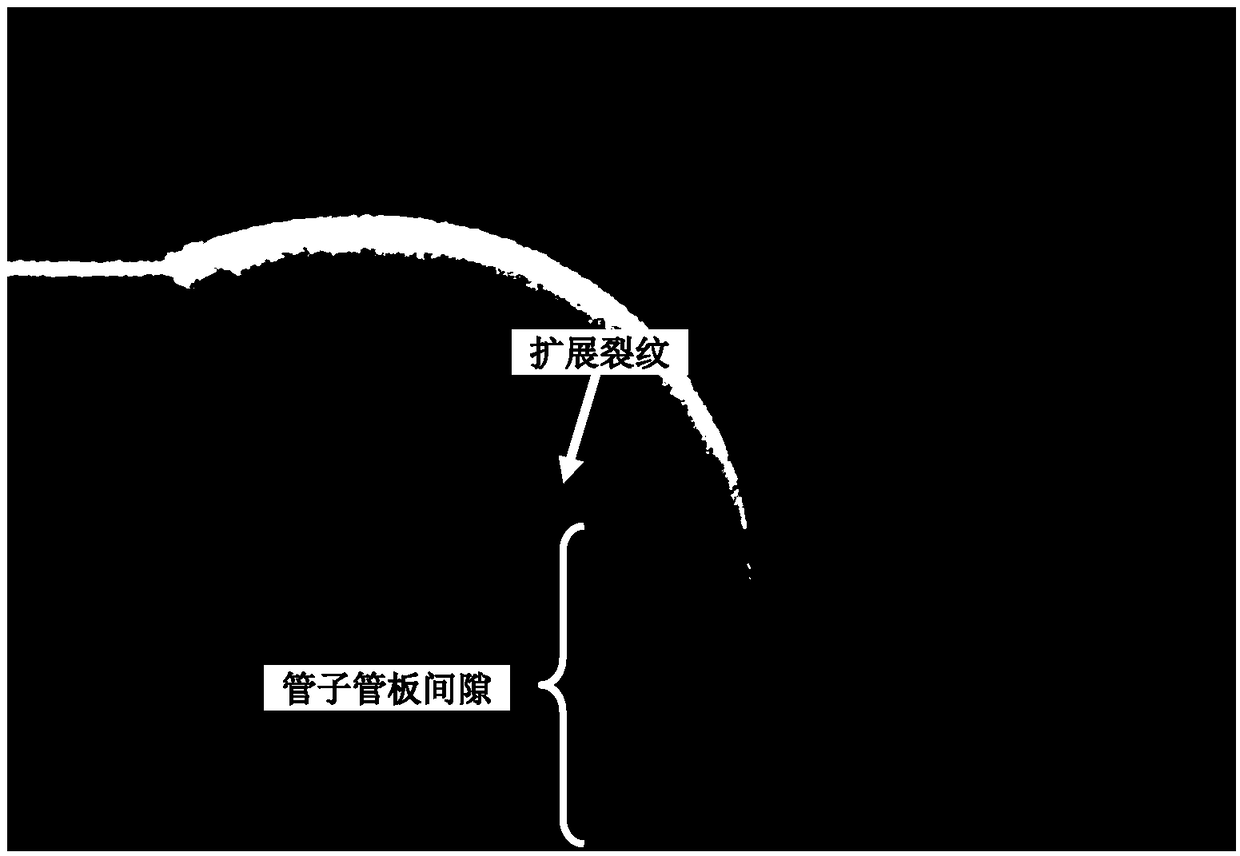

[0020] Such as figure 2 As shown, under the traditional weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com