Sand screening equipment for house construction

A kind of screening equipment and construction technology, which is applied in the direction of screening, application, solid separation, etc., can solve the problem of inconvenient sand classification and screening, and achieve the effect of reducing settings, increasing grinding force, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

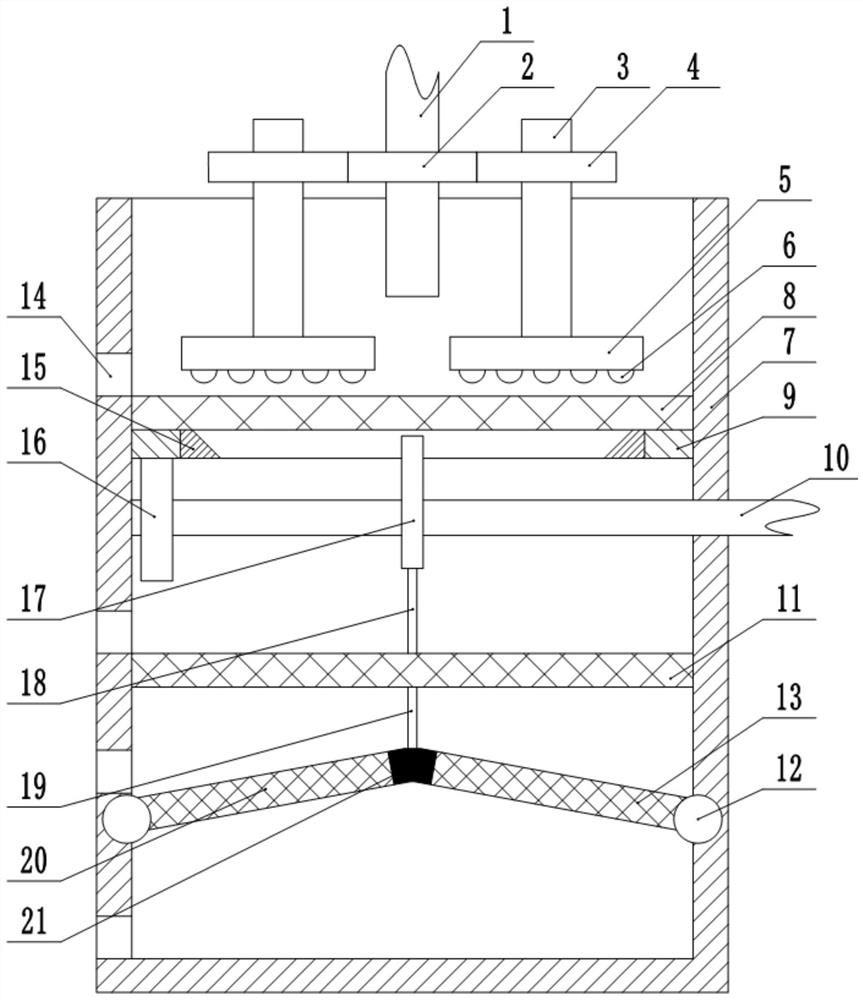

[0026] Such as figure 1 As shown, the sand screening equipment for house construction includes a frame, on which a screening box 7 is fixed, and the upper end of the screening box 7 is opened to form a sand feeding port. The hopper is used to drop the sand into the screening box 7 through the feed hopper.

[0027] The screening box 7 is provided with a rotating sieve 8, a sliding sieve 11 and a oscillating sieve in sequence from top to bottom, and the sieve apertures of the rotating sieve 8, sliding sieve 11 and oscillating sieve are successively reduced to achieve the purpose of grading and screening the sand layer by layer. . The side wall of the screening box 7 is provided with four outlets 14 respectively located at the bottom of the screening box 7, above the rotating screen 8, above the sliding screen 11, and above the swinging screen. A valve is installed in the outlet 14, and the outlets 14 are all connected There is a discharge pipe (not shown in the figure), and du...

Embodiment 2

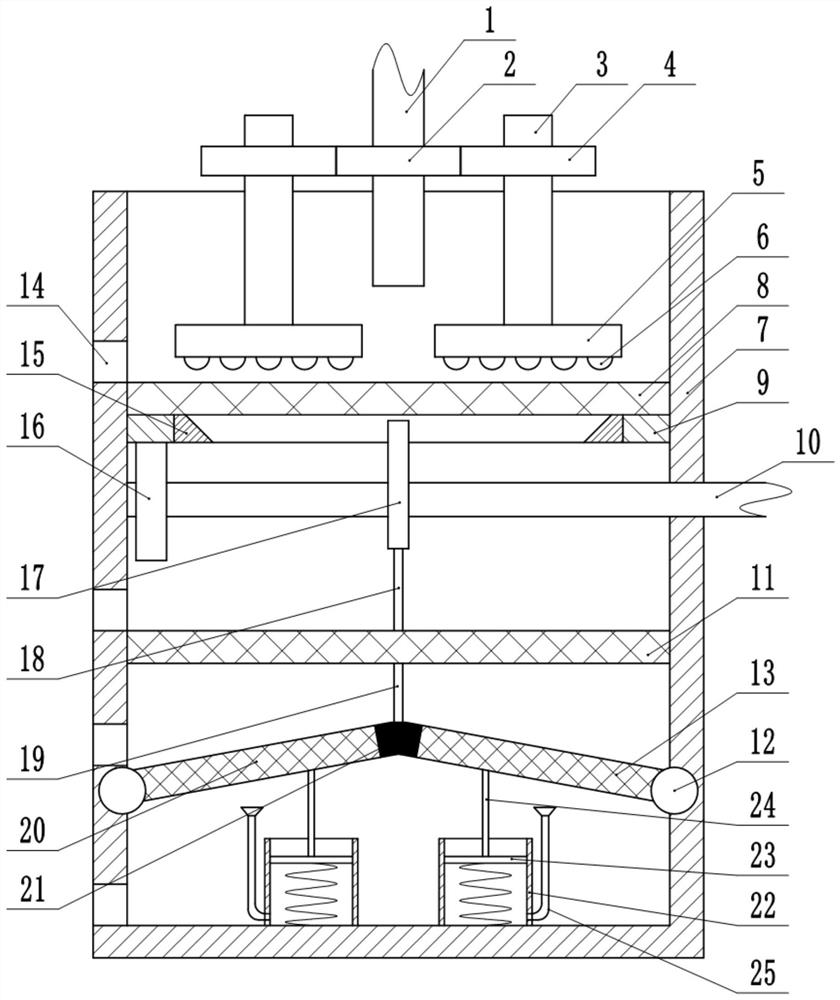

[0036] The only difference between this embodiment and embodiment 1 is: the combination figure 2 As shown, the first spring installed between the lower end of the opposite side of the first half sieve 13, the second half sieve 20, and the bottom of the screening box 7 is replaced by a piston barrel 22. Specifically, the piston barrel 22 is vertically slidably connected There is a piston 23, the upper end of the piston 23 is fixed with a piston rod 24, the upper end of the piston rod 24 is offset against the first half sieve 13 or the second half sieve 20, a second spring is fixed between the lower end of the piston 23 and the bottom of the piston barrel 22, and the piston barrel 22 Bottom is communicated with ventilator 25, and ventilator 25 openings face up and communicate with expanding mouthpiece, and filter cloth is fixed in the expanding mouthpiece, prevents sand from falling in the ventilator 25 by filter cloth.

[0037] In this embodiment, the first half sieve 13 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com