Casting model

A technology for casting models and base plates, applied in casting and forming equipment and other directions, can solve the problems of large workload and high grinding labor intensity, and achieve the effects of improving production efficiency, reducing labor intensity of workers, and reducing grinding volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

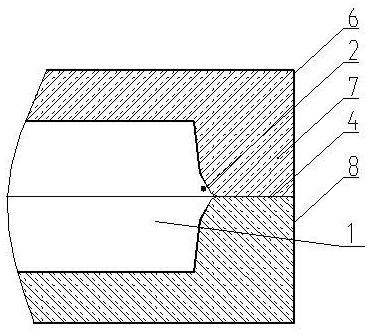

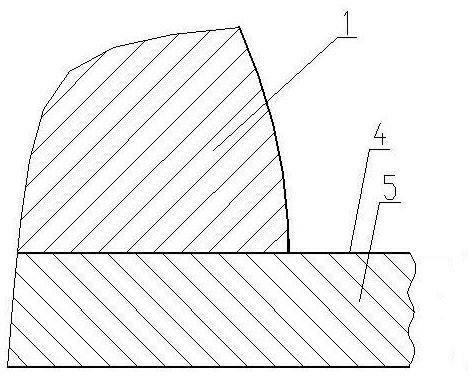

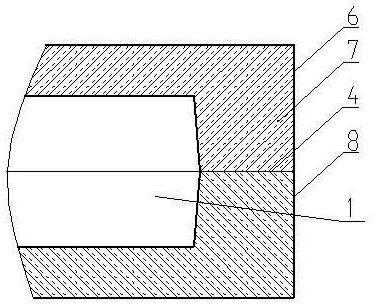

[0014] From figure 1 As can be seen in the figure, a casting model, the bottom of the model 1 in contact with the mold bottom plate 5 is provided with an embedded boss 3, and the mold bottom plate 5 is correspondingly provided with a step. The boss 3 is embedded on the step of the mold bottom plate 5, and the upper plane of the boss 3 and the upper plane of the mold bottom plate jointly form a parting surface 4, and a slope with an inclination of 60 degrees is provided at the corners of the parting surface 4 on the boss 3 2. The length of the base of the slope 2 is 1.5 mm.

[0015] In the present invention, a transition fillet of R1.5 is provided at the junction between the inclined surface 2 and the parting surface 4 . In this way, the processing of the model is facilitated, the integrity of the model structure is ensured, and the integrity of the sand mold is guaranteed; the formation of sticky sand and sharp-edged sand tires in the model can be eliminated during casting. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com