Method and system for erecting steel trusses by stay cable auxiliary complete cantilever

A technology of stay cable and steel truss girder, applied in the field of steel truss girder construction, can solve problems such as increased investment and increased load, and achieve the effects of short construction period, small investment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

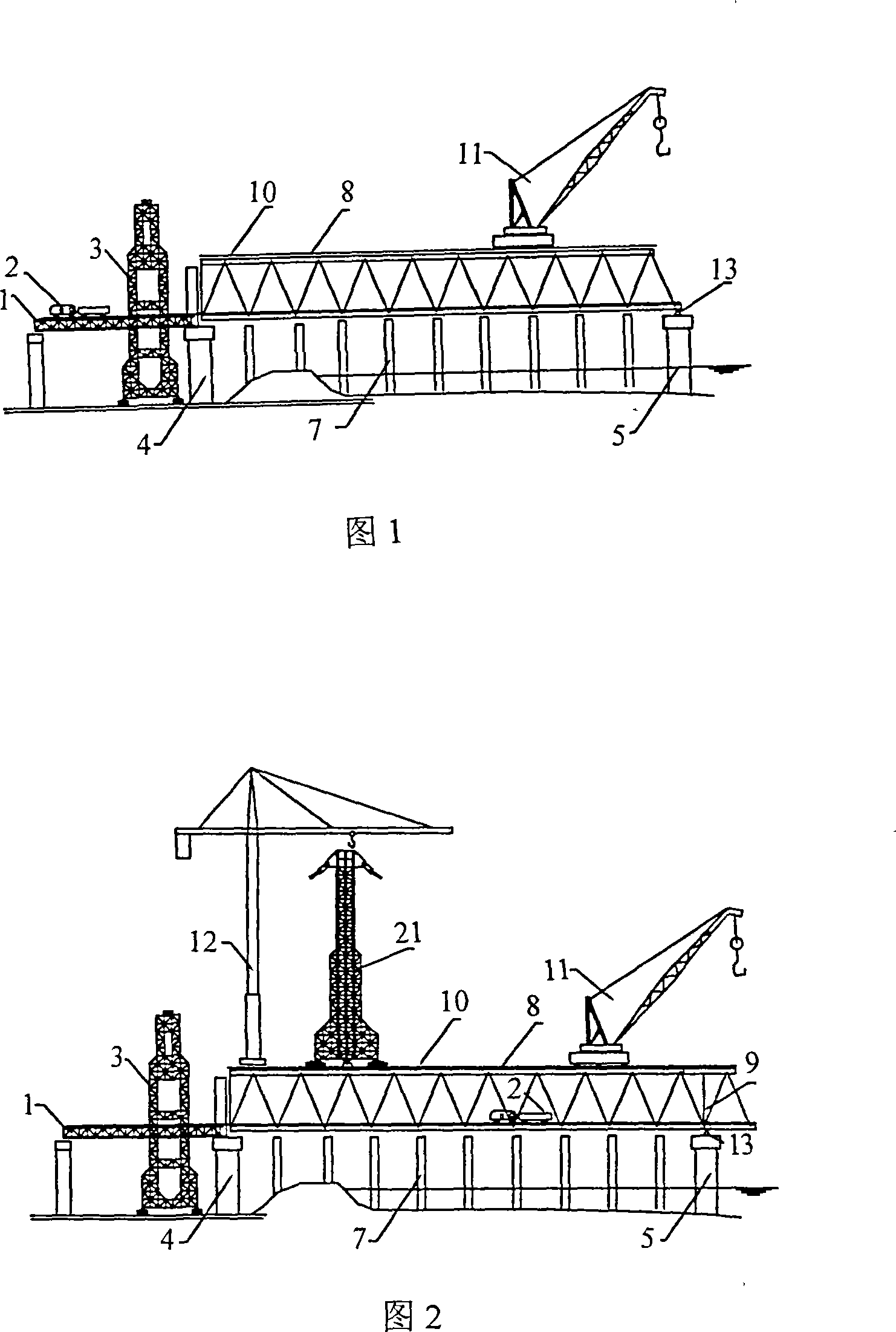

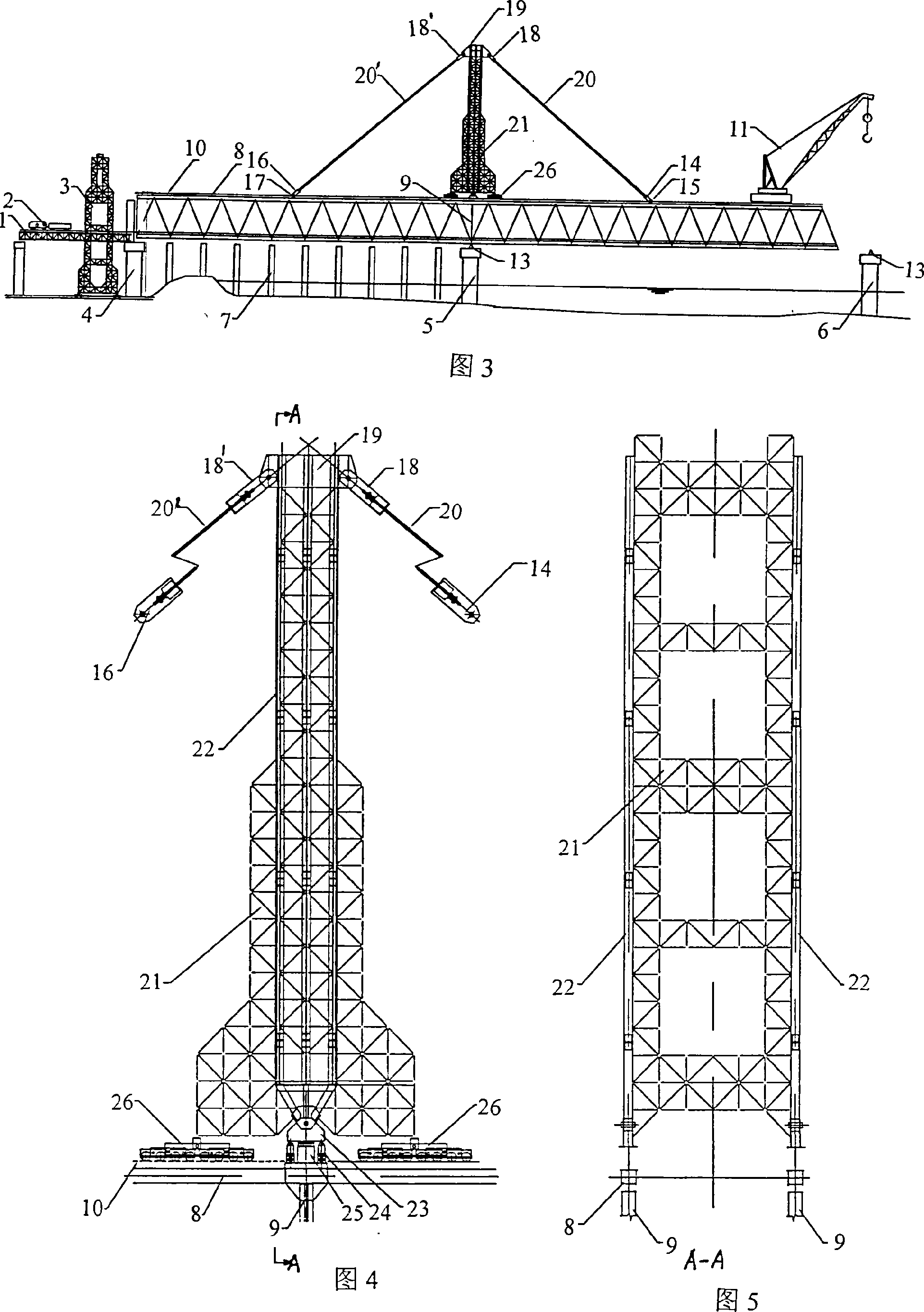

[0027] A method for erecting steel truss girders assisted by cable-stayed full cantilever, the specific steps of the method are as follows:

[0028] (1) Use a sling tower that combines a steel structure central tower column with stay cables. When applied to the erection of multi-span beams, the sling tower can be dragged and moved from one span to the next span by using the running structure installed at its lower part to erect steel truss girders. The stay cables are multi-cable group cables of one or more layers system.

[0029] (2) After the steel truss girder of the first hole is assembled on the frame, use the elevated gantry crane at the ground lifting station to install the large tower crane located on the top surface of the steel truss beam end of the first hole, and then assemble it with the tower crane Suspend the upper and lower supporting bases of the tower, the central column, the auxiliary truss and the anchor beam at the top of the tower, and then anchor the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com