Positive/negative pressure vacuum film covering machine

A vacuum laminating machine, positive and negative pressure technology, applied in the direction of press, lamination, lamination device, etc., can solve the problems of poor product consistency, difficult to guarantee product quality stability, easy to be affected by the external environment, etc. Reliable performance, low cost, and intuitive action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

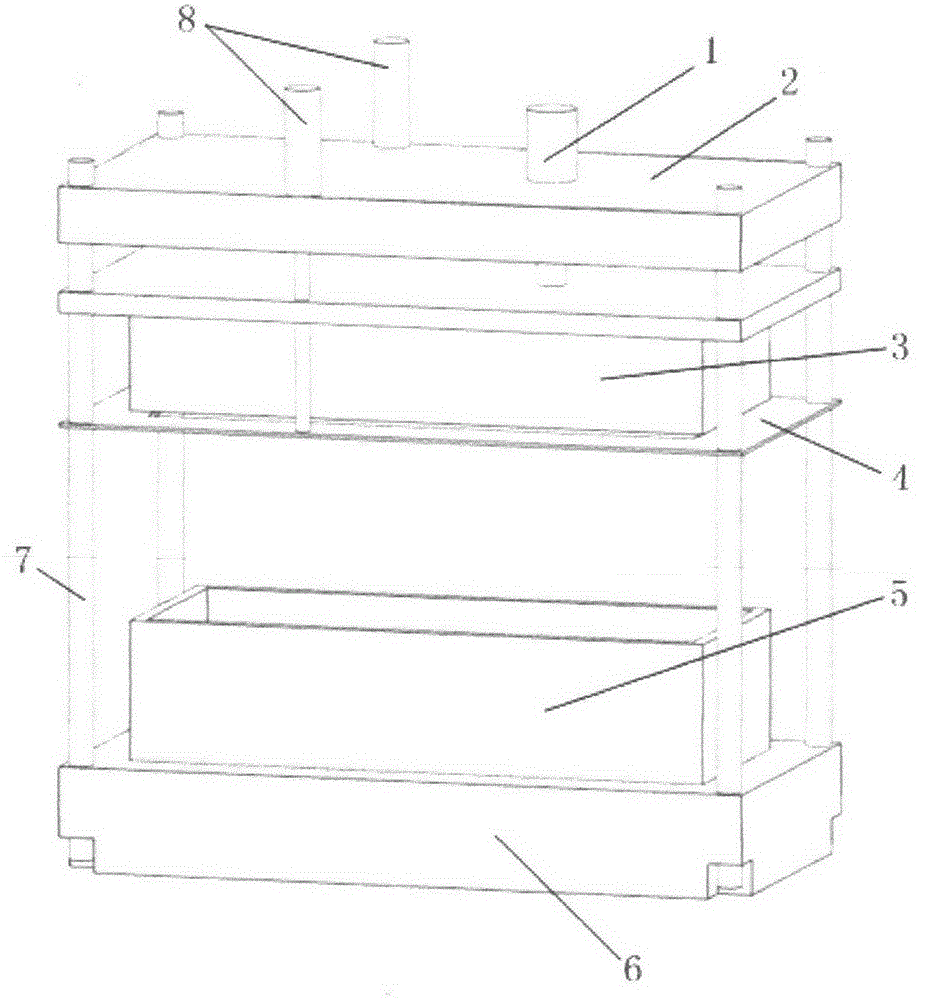

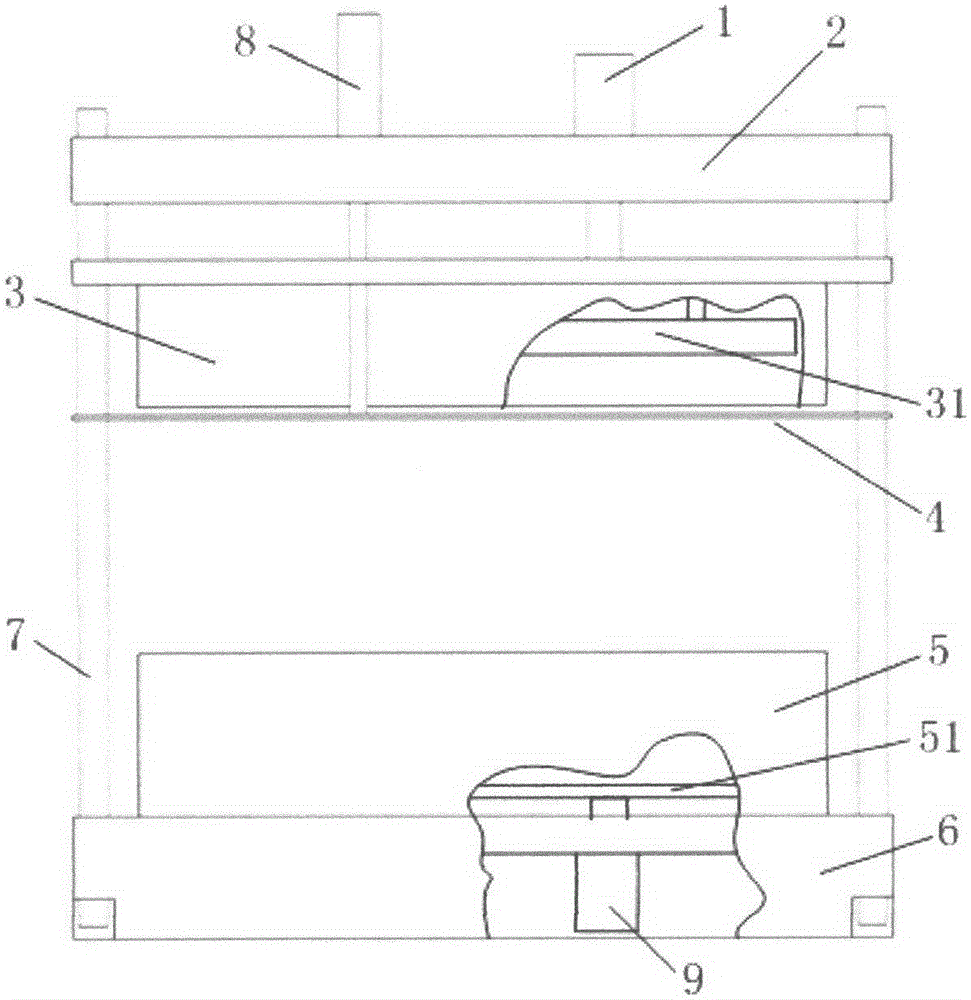

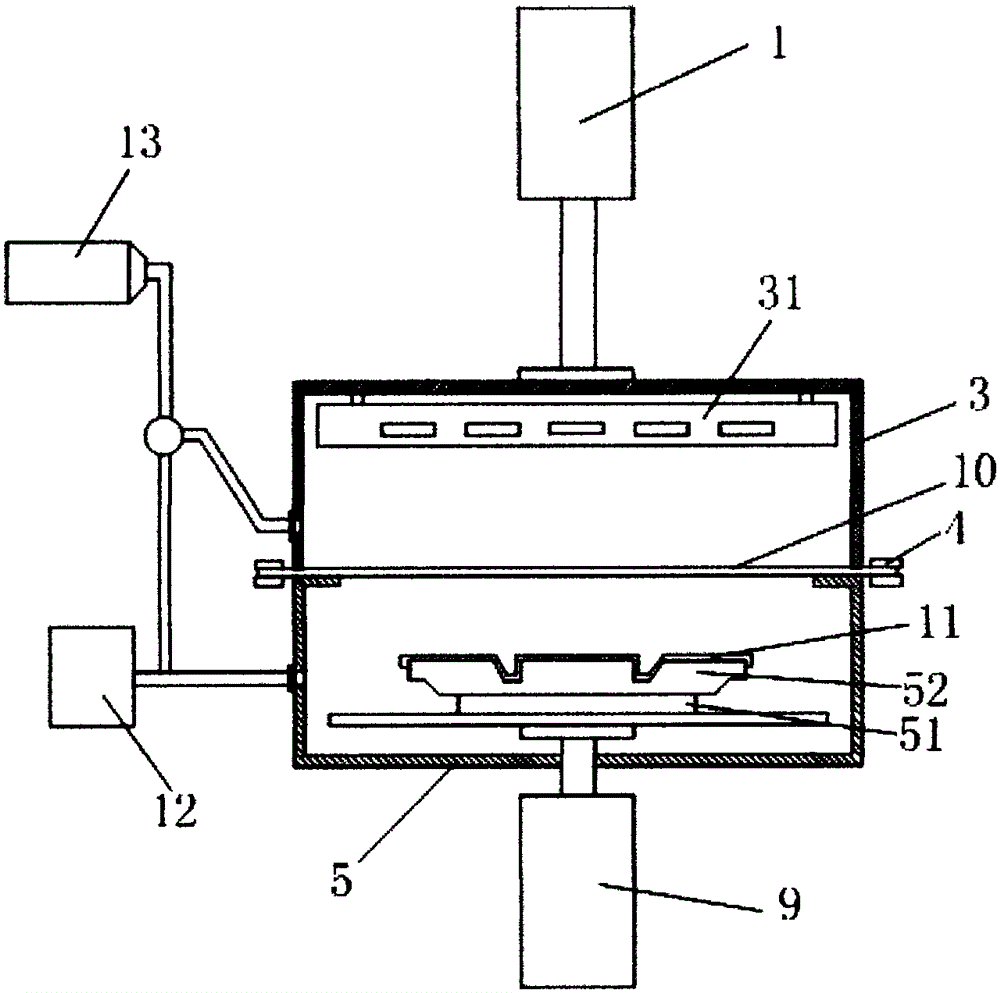

[0026] A positive and negative pressure vacuum laminating machine is composed of five parts: a main machine, a hydraulic system, a heating system, an electrical system, and a positive and negative pressure system. The host is as attached to the manual Figure 1~3 As shown, it includes an upper cylinder 1, an upper beam 2, an upper vacuum chamber 3, a film pressing plate 4, a lower vacuum chamber 5, a lower beam 6, a column 7, a film pressing cylinder 8 and a lower cylinder 9, etc., and the upper vacuum chamber 3 A heating system 31 is fixed inside, a carrying platform 51 is installed inside the lower vacuum chamber 5 , and a carrying jig 52 is installed on the carryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com