Semiactive piezoelectric friction damper

A friction damper, semi-active technology, applied in the direction of spring/shock absorber, vibration suppression adjustment, building components, etc., can solve the problem of unable to adjust the sliding friction force, etc., to achieve the effect of ensuring stability and ensuring the safety of people's lives and property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

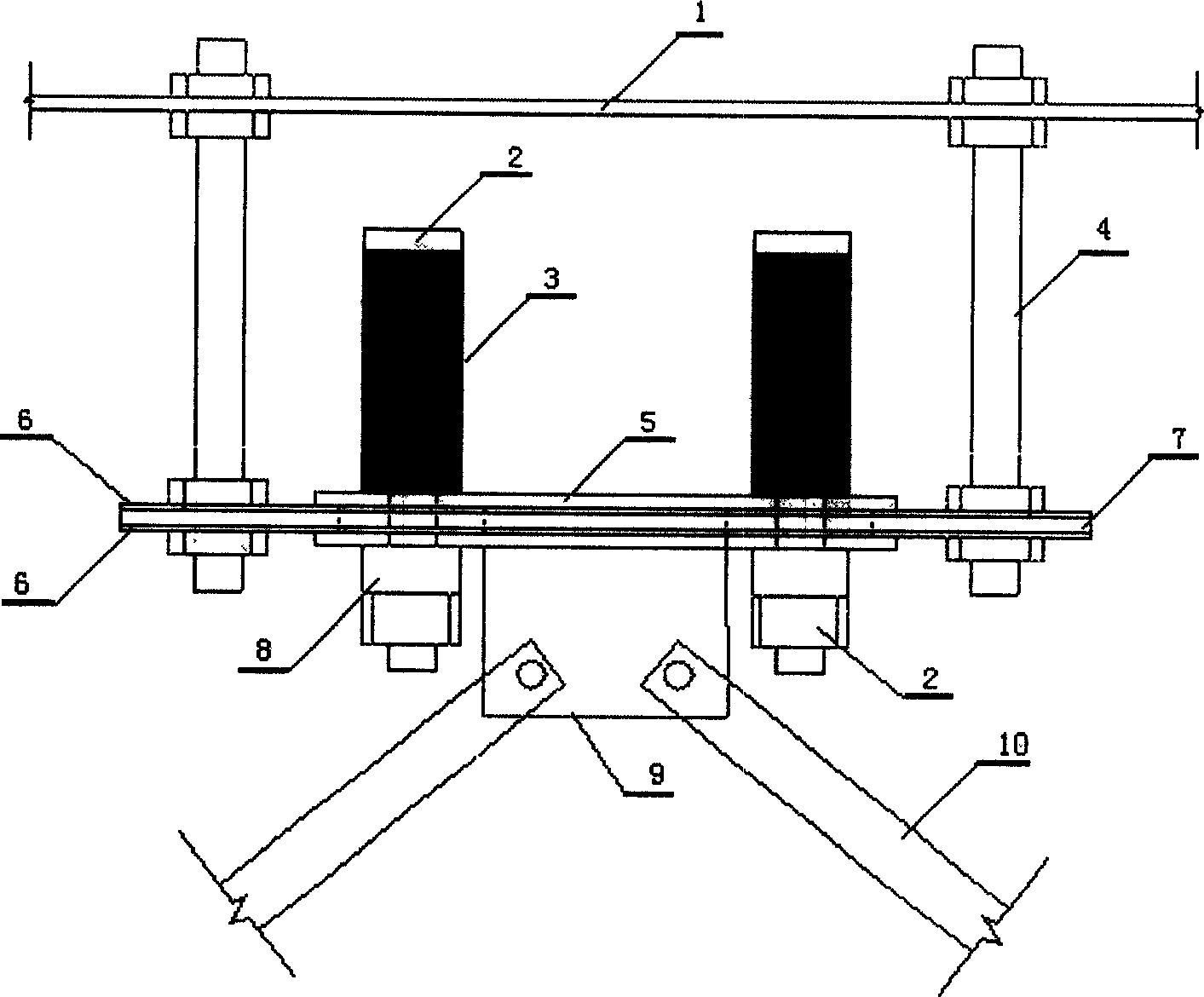

[0017] The implementation steps of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

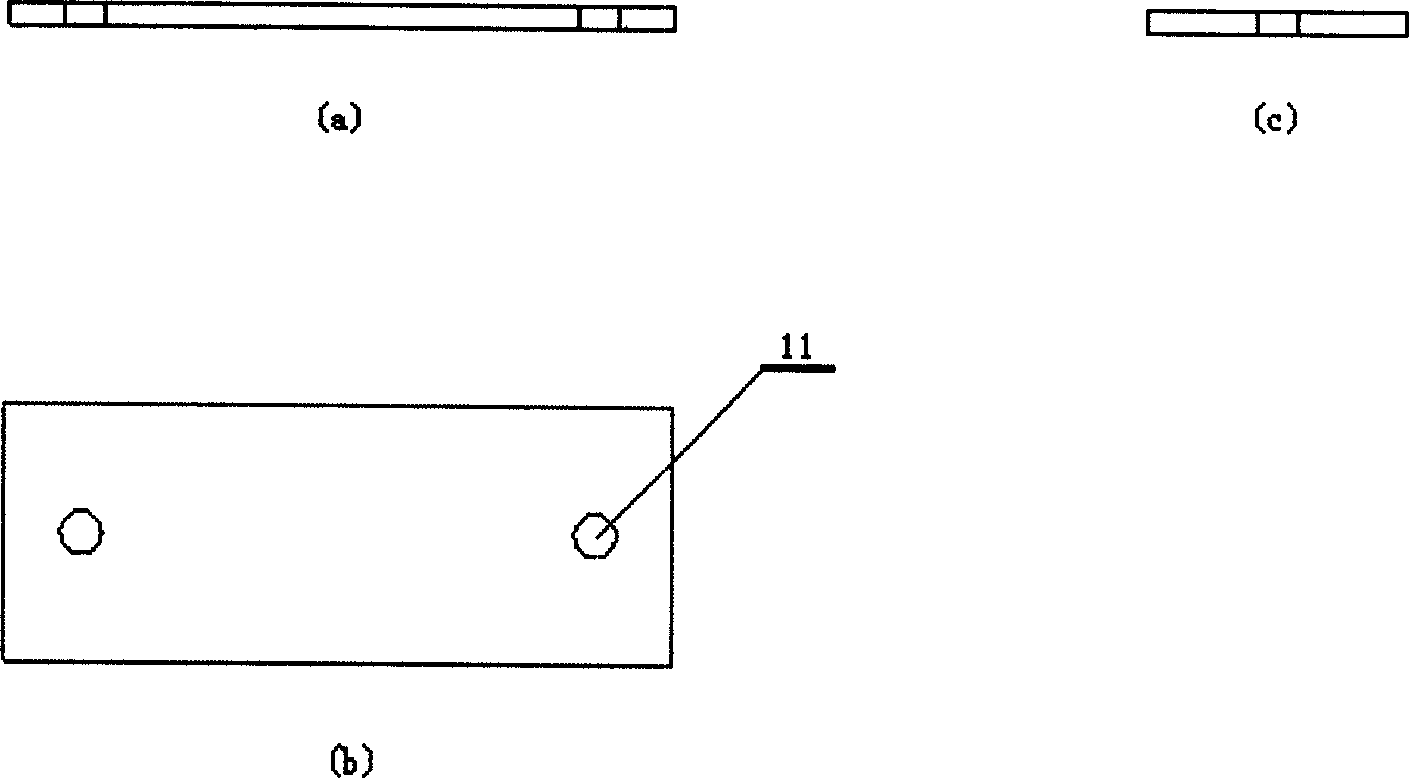

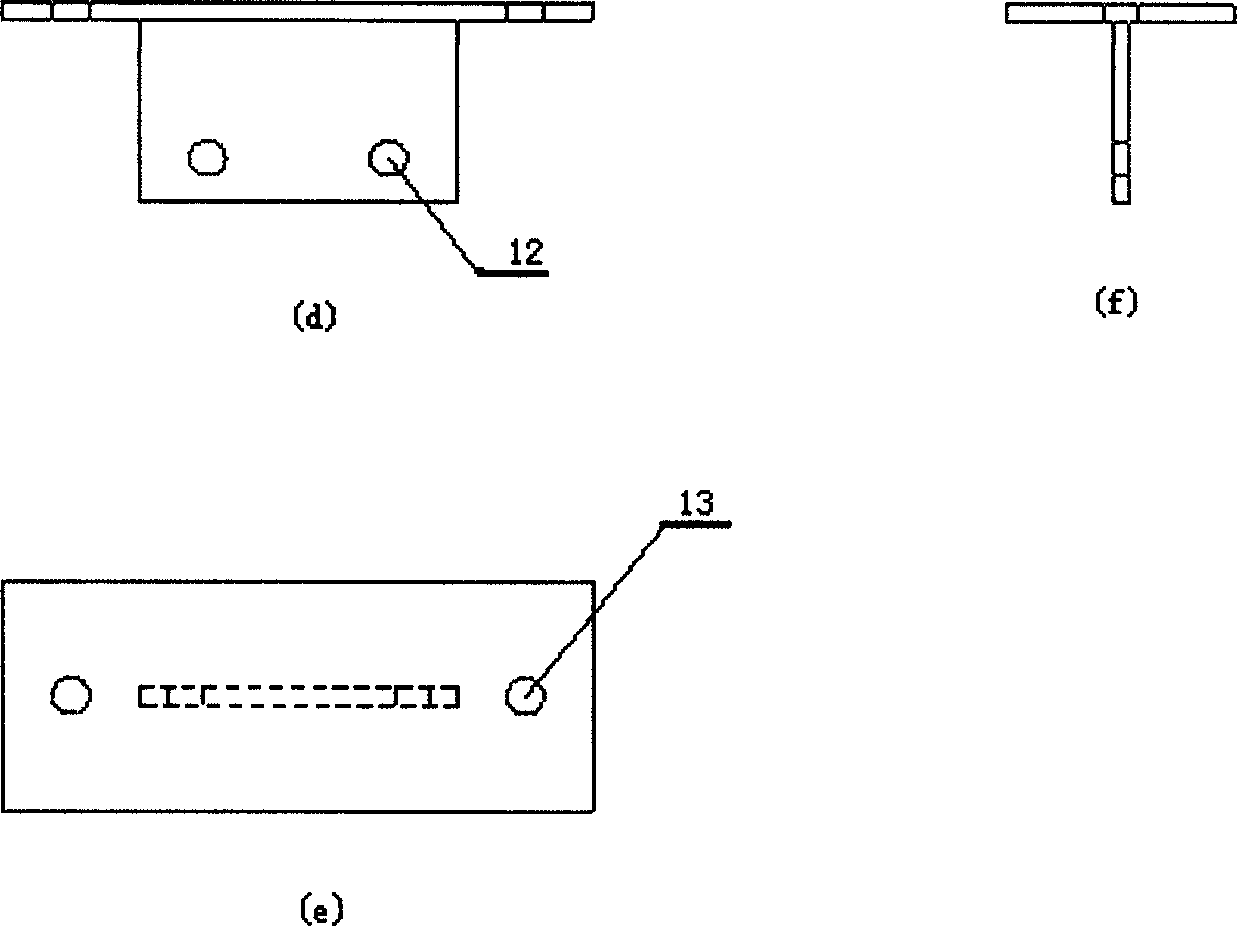

[0018] During the implementation, firstly, the engineering structure is analyzed under the action of small and large earthquakes, and according to the adopted control algorithm, the minimum sliding friction force and the maximum sliding friction force to be provided by the semi-active piezoelectric friction damper are respectively determined, and the design Dimensions and parameters of the semi-active piezoelectric friction damper; secondly, process the required upper steel plate 5, lower steel plate 9, sliding plate 7 and friction plate 6, and design or purchase the piezoelectric ceramic driver 3 and force sensor 8 that meet the design requirements ; Again, the positive pressure corresponding to the minimum sliding friction force is used as the pre-tightening force, which is applied to the piezoelectric ceramic driver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com