Footwear Sole Structure with Suspended Elastomeric Web or Mesh Support

a technology of elastomeric web and shoe sole, which is applied in the field of shoe sole structure with suspended elastomeric web or mesh support, to achieve the effects of reducing the energy exerted by the wearer, accentuating the comfort of the shoe, and softening the pressure applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

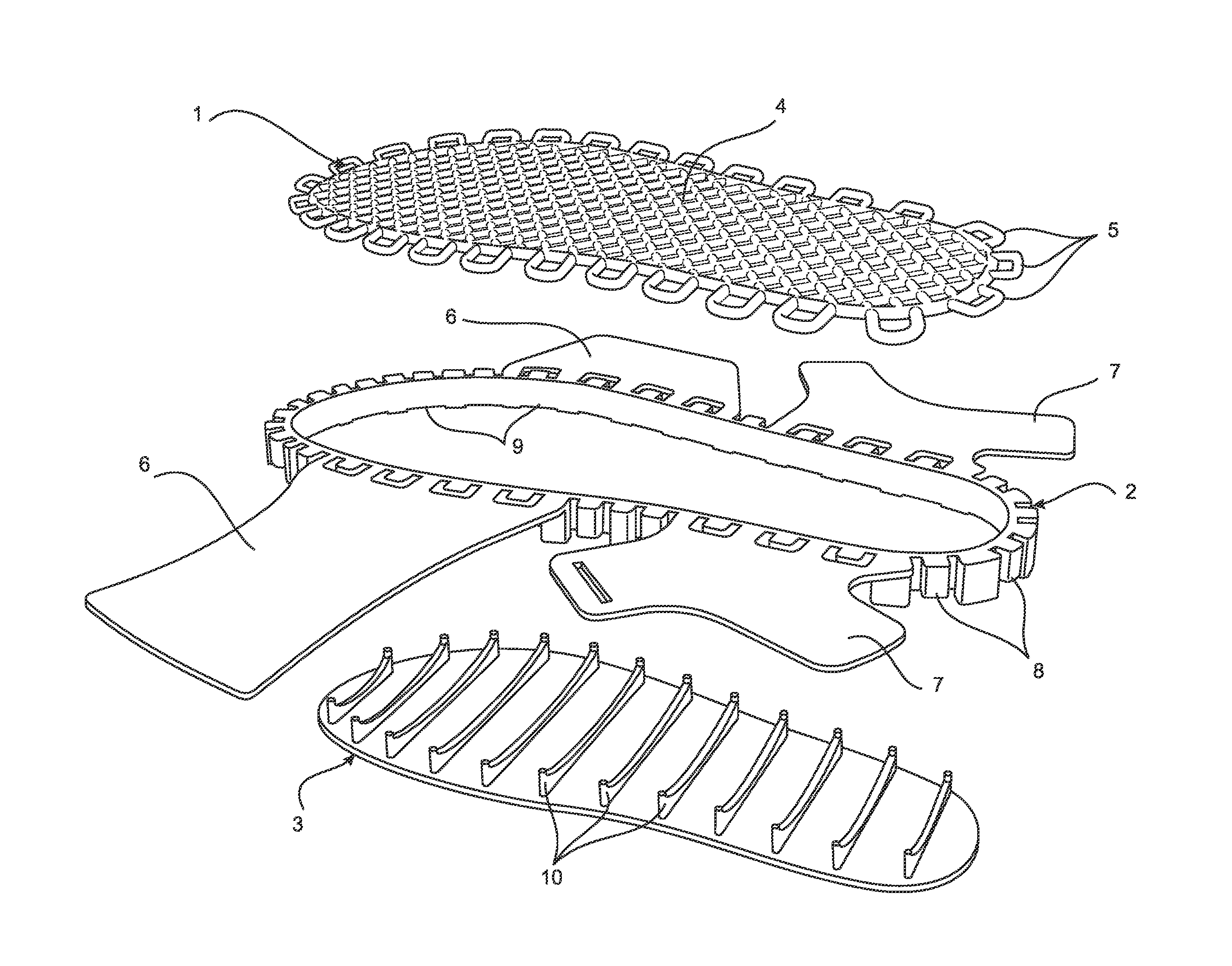

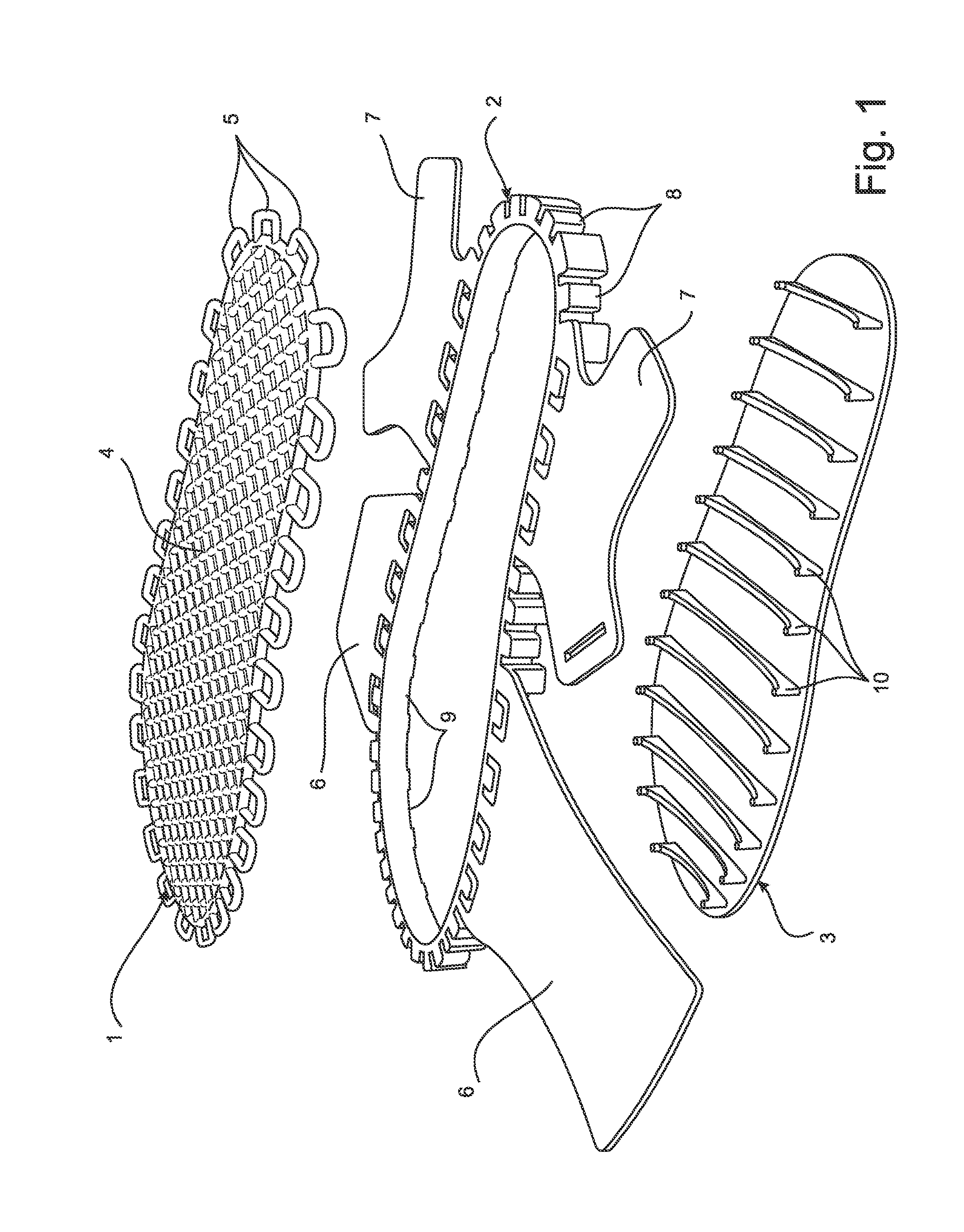

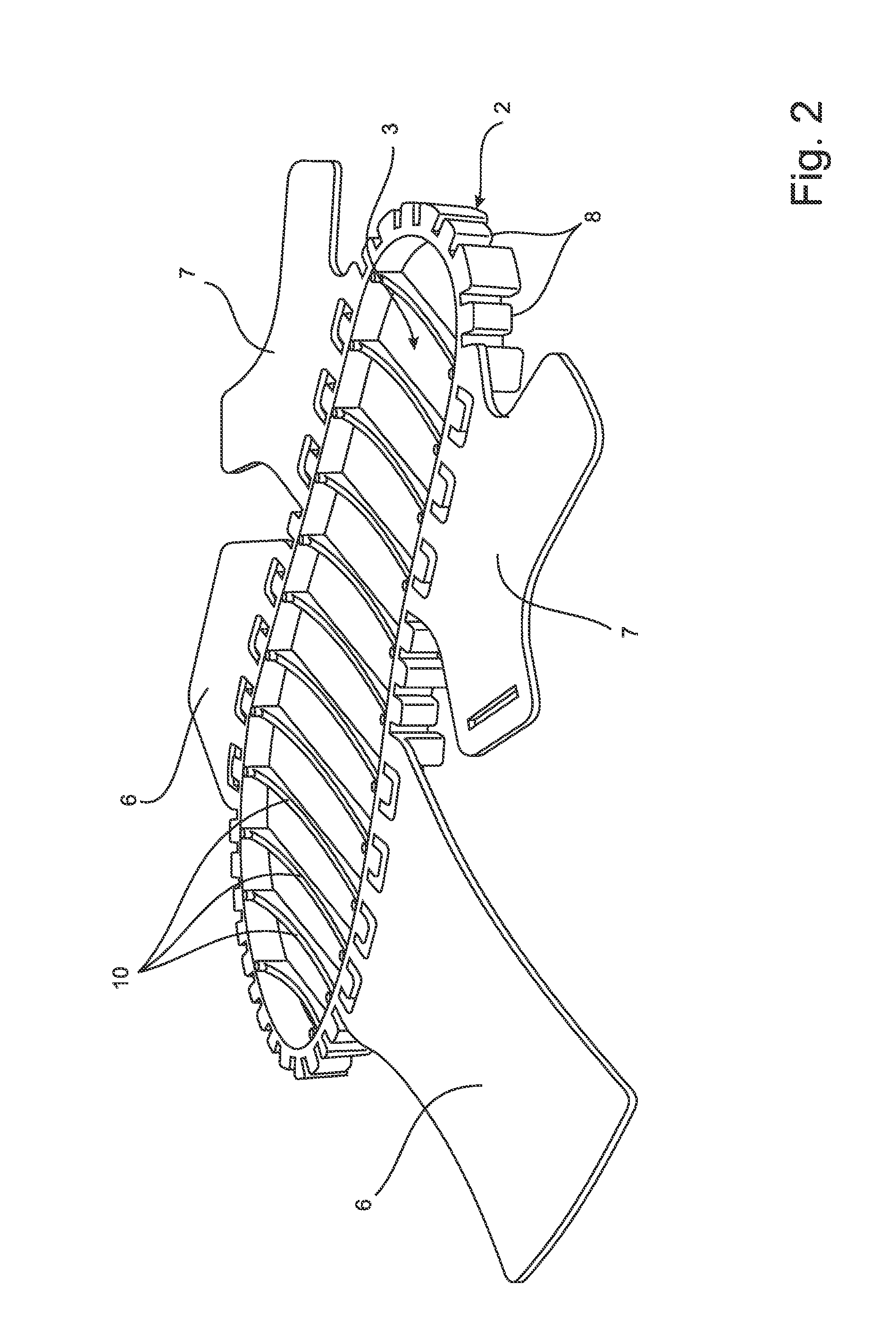

[0062]FIG. 1 is an example of the footwear embodying the present invention as described above, being a rear angled perspective view of the three main components:[0063](a) at the top, a typical elastomer web / mesh 1 in a diagonal grid style pattern 4 and with outer connection loops 5,[0064](b) in the middle, the central body 2 being a single part moulding incorporating a front strap pair6, rear strap pair 7, lugs 8 and inner lip 9, and[0065](c) at the bottom, the higher density elastomer sole 3 featuring curved cross-brace supports 10; wherein the higher density sole 3 fits up and is bonded (or even moulded together as one part) into a matching lip 9 in the base of the central body 2 (see upwards direction arrows) and the elastomer web 1 fits down over the central body 2 such that the web loops 5 stretch around corresponding lugs 8 on the central body 2 (see downward direction arrows) such that the web / mesh 1 is largely held in pre-tension via the supports 10 and there is still space ...

second embodiment

[0072]FIG. 5 is an example of the structure described, being a side view of a structure showing a higher density elastomer cover / outer 30 fitted with a web or mesh supporting system consisting of (on each side of the shoe) ‘comb’ structures 28, the bottom sections of which incorporate ‘teeth’24 which insert into matching slots in the cover / outer 30 and the top sections of which hold the web or mesh 20 end loops 22. When the comb 28 teeth 24 are inserted into the cover / outer 30 the web or mesh 20 is stretched across from side to side and held in position and under pre-tension via the end loops 22 hooked over the top lugs of the comb 28 supports.

[0073]FIG. 6 is an example of the same second embodiment of the Web-Shoe described in FIG. 5, being three exploded cross-sectional explanatory views of the structure in FIG. 5 showing a higher density elastomer cover / outer 30 fitted with a Web supporting system on each side of the cover / outer 30 consisting of ‘comb’ structures 28, the bottom s...

third embodiment

[0074]FIG. 7 is an example of the structure described, being three side views and two cross-sections of a system 40. The top side view shows the complete system 40 and the two side views below that show detailed section side views of an H-Section mid-section 48 incorporating mesh 20 throughout the middle with vertical edge sections around the periphery that incorporate peg holes 42. Also shown is the higher density elastomer sole 44 that incorporates the U-shaped metal or stiff wire pegs 46. The horizontal sections of the pegs 46 provide lateral stiffness to permit the web or mesh 20 to be pre-stretched and the vertical sections of the pegs 46 slot into matching recess peg holes 42 in the H-section 48 above it.

[0075]FIGS. 8 and 8A show an example of a fourth and simplest embodiment of the structure described, being an exploded perspective view (FIG. 8) and top / plan view (FIG. 8A) of the two main parts of the lower shoe section of a Web-Shoe. The section 90 is the single piece moulde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com