Well lid structure for reducing and avoiding vertical draining well blowout and response method thereof

A technology for manhole covers and shafts, applied in drainage structures, underwater structures, infrastructure engineering, etc., can solve the problems of less research and achieve the effects of increasing the channel area, weakening the blowout intensity, and inhibiting the occurrence of blowouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

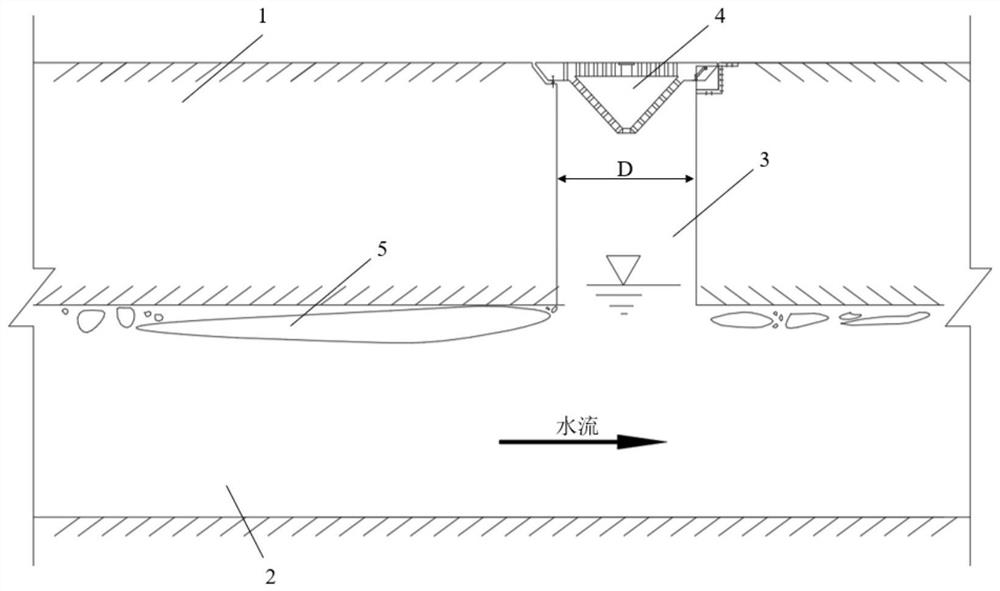

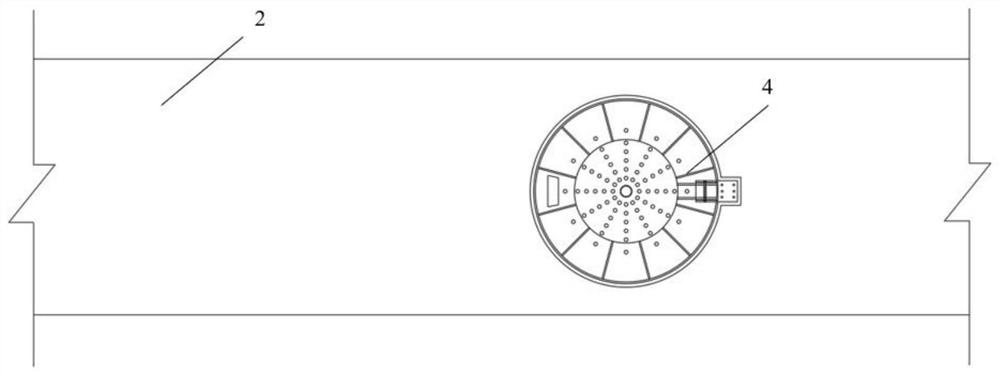

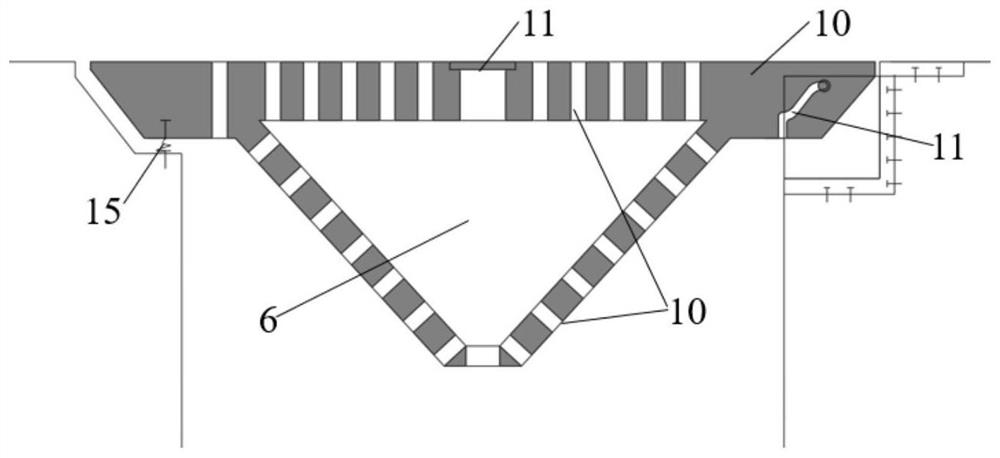

[0034] A schematic diagram of the manhole cover structure for reducing blowout in the drainage shaft is shown in figure 1 and figure 2 , the shaft 3 communicates with the atmosphere on the ground 1 and the underground pipeline 2 , and the well cover 4 assembly is arranged on the top of the shaft 3 . The structure of manhole cover 4 components is as follows Figure 3 to Figure 5 As shown, it mainly includes the following components: well cover 4 cavities, well cover 4 bases, well cover 4 supports, well cover 4 hinges, well cover 4 ribs, rib track 11, air hole 12, middle hole 13, well cover 4 handles, Limit soft rope 15, hook, cushion 17. The well cover 4 is a conical body with a circular (or square) flat plate. When in use, the flat plate is placed horizontally and flush with the ground 1. The manufacturing material is generally cast iron, plastic, concrete or synthetic material, and the gravity is G.

[0035] The shape of the cavity of the well cover 4 is an inverted cone,...

Embodiment 2

[0041] Embodiment two: if Figure 6 , the well cover structure can also include a well cover base 18, a rib that is symmetrically welded on the two side walls of the well cover, and two flaps 21 that are rotated inside the well cover base 18; It is used to connect the driving part 19 of the driving link and the driven part 20 for connecting the turning plate 21; the turning plate 21 includes a rotating shaft 22 and a semicircular plate body, and the two semicircular plate bodies are completely covered when closed. Inside the well cover base 18, a plurality of reinforcing plates 23 that are mutually symmetrical to each other at 90° to the axis of the rotating shaft 22 are arranged between the rotating shaft 22 and the plate body; The first connecting rod 24 and the second connecting rod 25 connected by the interference fit of the rotating shaft 22, and the third connecting rod 26 hinged between the first connecting rod 24 and the second connecting rod 25, the first connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com