Buffering equipment of logistics carrying platform

A technology of buffer equipment and logistics handling, which is applied in the directions of transportation and packaging, loading/unloading, packaging, etc. It can solve the problems that the handling platform does not have buffering and height adjustment functions, and achieve the effect of easy installation and disassembly, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

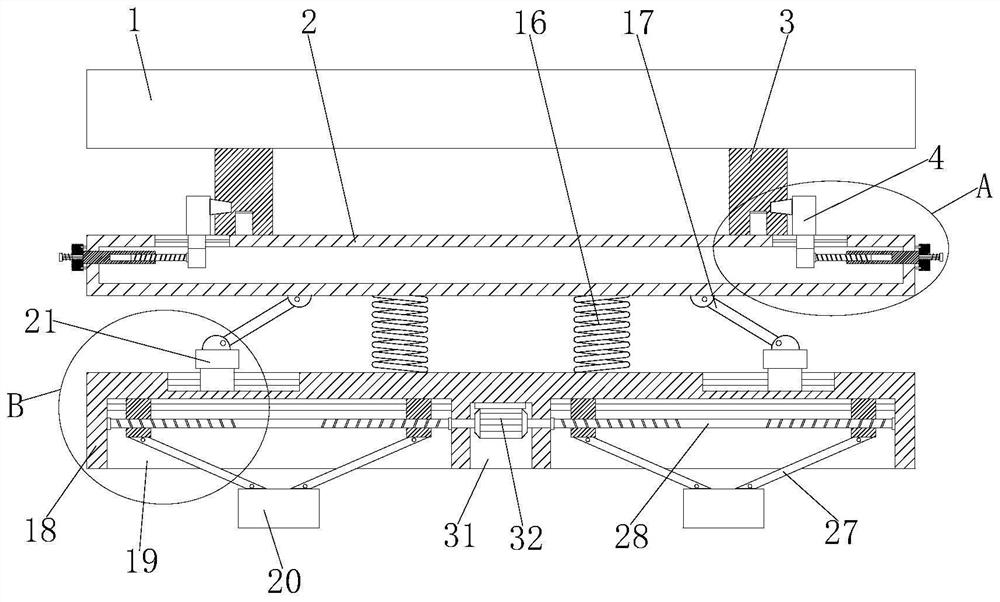

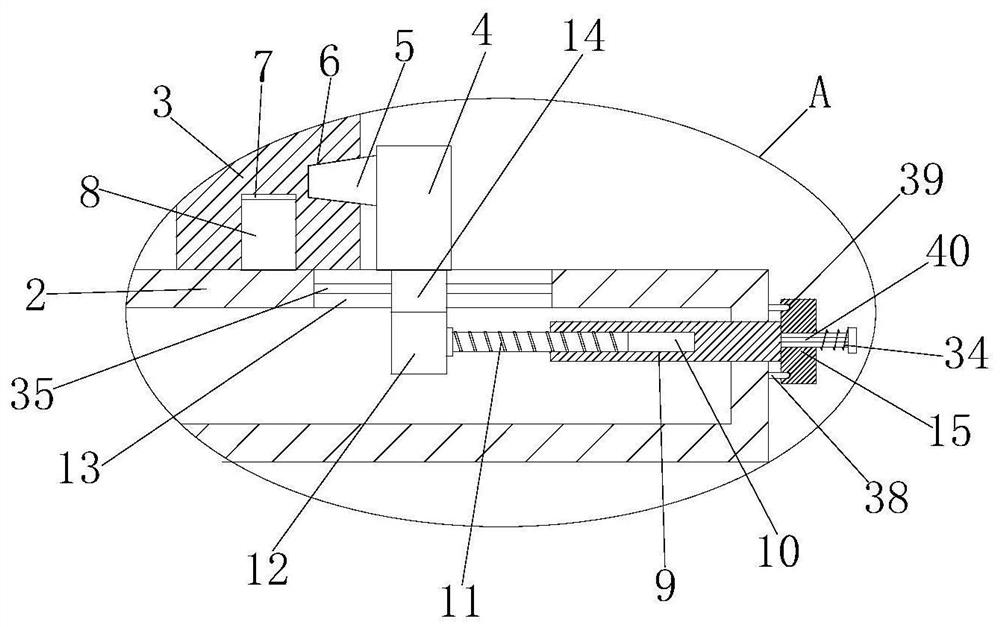

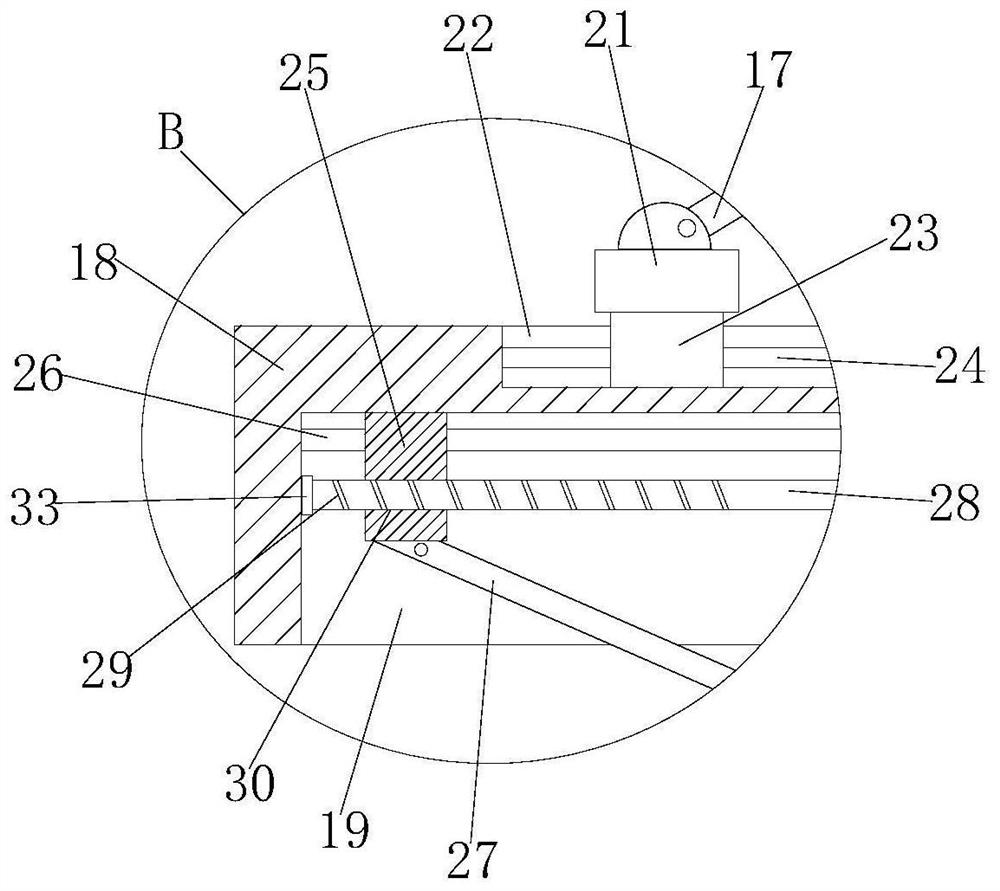

[0029] refer to Figure 1-5 , a buffer device for a logistics handling platform, comprising a handling platform 1, four mounting legs 3 are fixedly connected to the bottom of the handling platform 1, the bottom of the four mounting legs 3 is provided with the same rectangular box body 2, and the rectangular box body 2 Both sides are equipped with circular rods 9, and the ends of the two circular rods 9 are provided with spiral grooves 10, and the two spiral grooves 10 are threaded with screw rods 11, and the two screw rods 11 are close to each other. Push bars 12 are installed on one end, and the tops of the two push bars 12 are fixedly equipped with two hole blocks 14. The top of the rectangular box body 2 is provided with four sliding holes 13, and the hole blocks 14 are connected with the corresponding slide holes. 13 Sliding connection, the top of the rectangular box body 2 is symmetrically slidably installed with two push plates 4, the push plates 4 are fixedly installed ...

Embodiment 2

[0040] refer to Figure 1-5 , a buffer device for a logistics handling platform, comprising a handling platform 1, the bottom of the handling platform 1 is fixedly connected with four mounting legs 3 by screws, the bottom of the four mounting legs 3 is provided with the same rectangular box body 2, the rectangular box body Both sides of 2 are equipped with circular rods 9 for rotation, and one end of the two circular rods 9 close to each other is provided with a spiral groove 10, and the two spiral grooves 10 are internally threaded with a screw rod 11, and the two screw rods 11 are connected to each other. Push bar 12 is all rotated and installed near one end, and the tops of two push bars 12 are fixedly installed with two hole blocks 14 by welding, and the top of rectangular box body 2 is provided with four sliding holes 13, and hole block 14 and The corresponding sliding holes 13 are slidingly connected, and the top of the rectangular box 2 is slidably installed with two pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com