Reinforcing system and reinforcing method of wind power generation tower foundation ring foundation

A foundation ring and foundation technology, which is applied in the field of wind power tower foundation reinforcement, can solve problems such as foundation ring foundation cracking and damage, and achieve the effect of solving cracking, fatigue damage, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

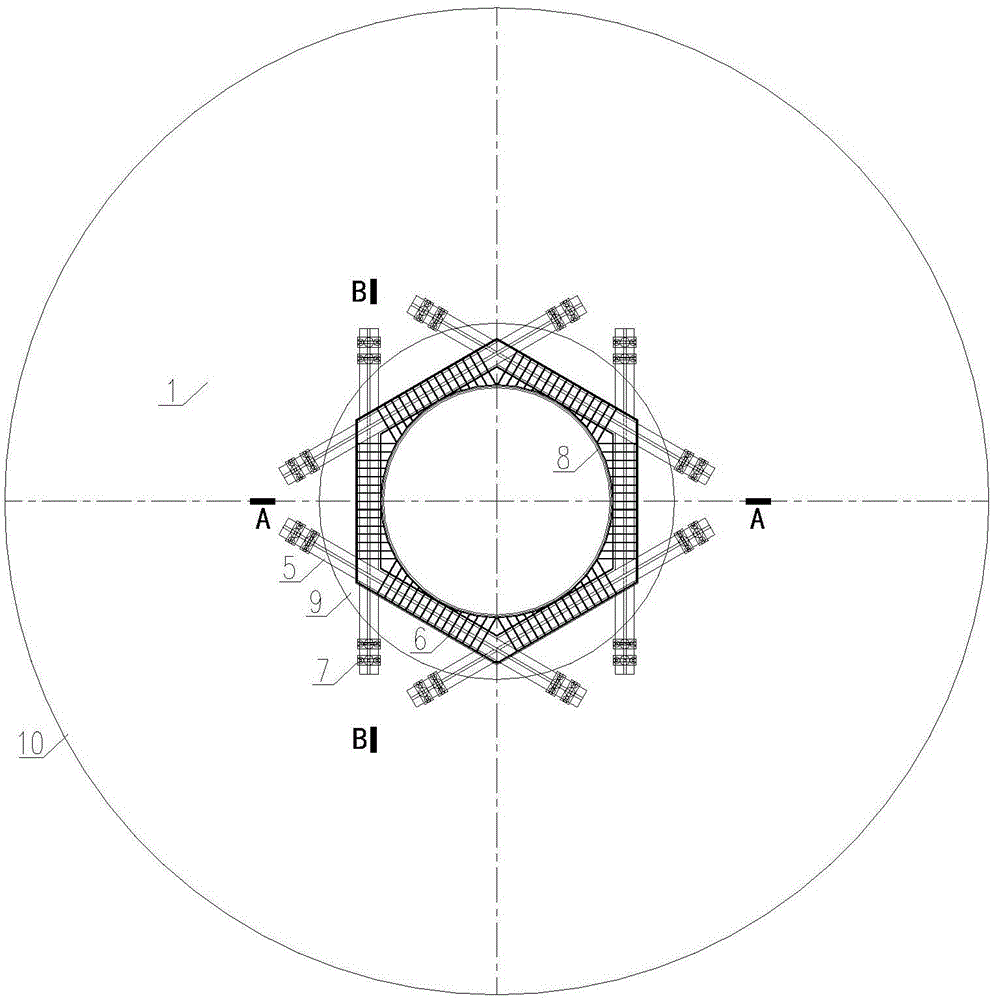

[0033] Such as Figure 1 to Figure 5 Shown, a kind of reinforcing system of foundation ring foundation of wind power generation tower, its this system comprises:

[0034] The foundation ring foundation (1) and the fan tower (2), the foundation ring foundation (1) includes the foundation bottom plate (10), the concrete column pier (9) connected to the foundation bottom plate (10), the lower end is embedded in The foundation ring (8) inside the concrete pier (9), the upper end of the foundation ring (8) is connected to the fan tower (2) through a flange;

[0035] There are 6 steel beams (5) arranged symmetrically on the outside of the foundation ring (8) and the top of the concrete pier (9), the intersections of two adjacent steel beams (5) are welded, and bolts are used in the middle of the steel beams (5) Splicing; 6 steel beams (5) form a regular hexagonal area around the foundation ring (8), and steel reinforced concrete beams (6) are poured around the regular hexagonal ste...

Embodiment 2

[0040] Such as Figure 1 to Figure 5 Shown, a kind of wind power generation tower foundation ring foundation reinforcement method is characterized in that, comprises the following steps:

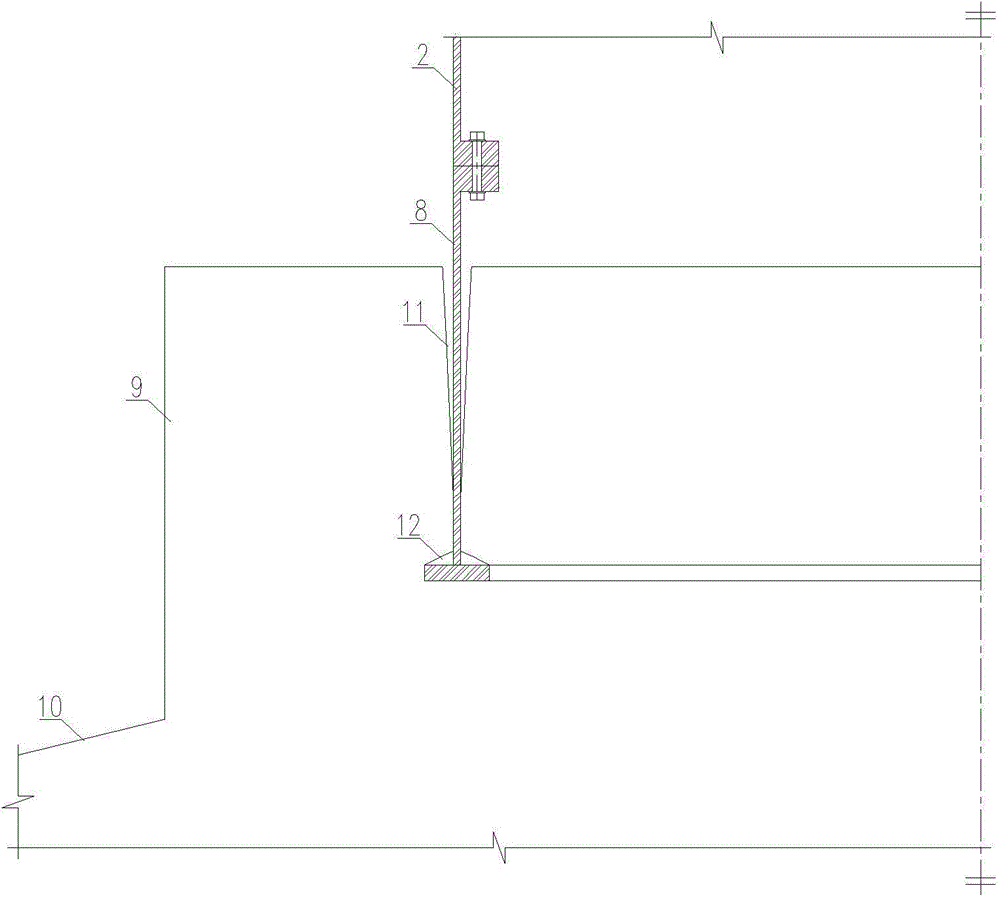

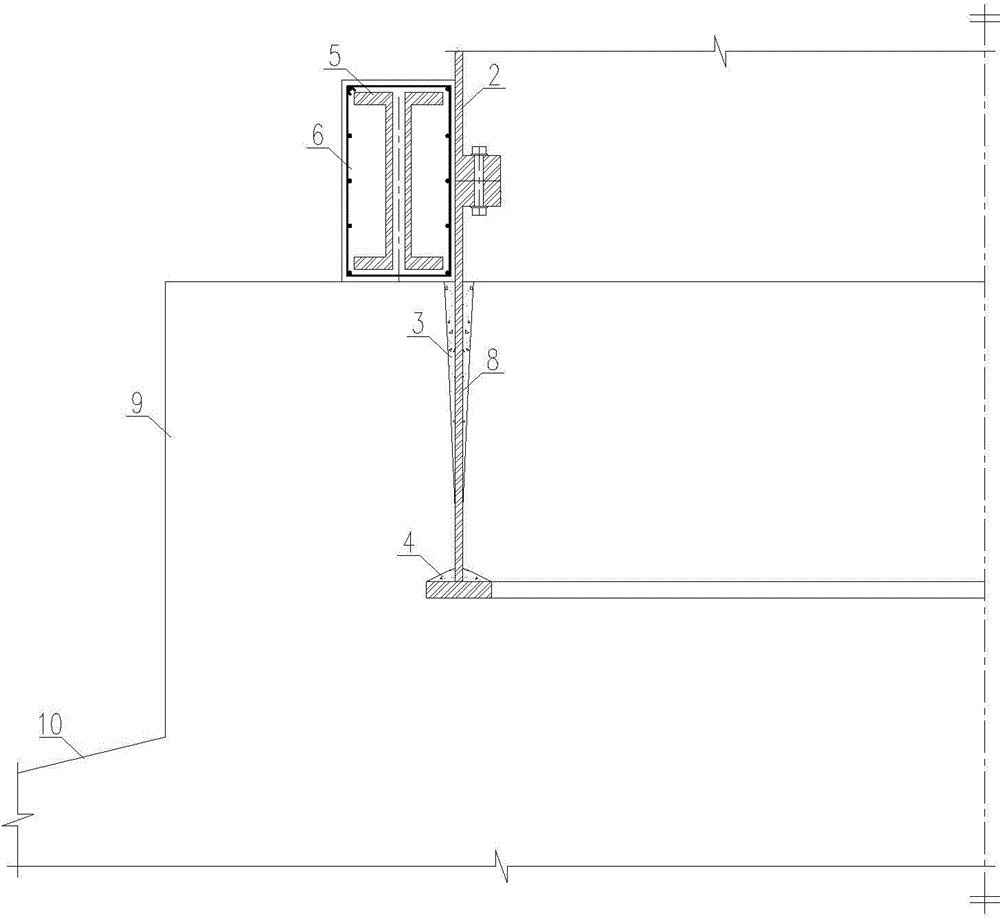

[0041] a. Inject the high-strength grouting material into the damaged cavity (12) above the bottom flange of the foundation ring (8) to form a high-strength grouting material (4);

[0042] b. Inject epoxy resin into the crack (11) between the foundation ring (8) and the pier (9) to form epoxy resin caulking (3);

[0043] c. Drill a hole on the base plate (10), insert the lower anchor rod (15), inject epoxy resin (16) into the outer periphery of the lower part of the lower anchor rod (15), and put a PVC sleeve on the upper part of the lower anchor rod (15) ( 17), then pour the high-strength mortar block (18) on the top surface of the foundation base plate (10), then place the transfer beam (14) on the high-strength mortar block (18), tension the anchor rod (15) and place it Anchored on the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com