Noise source identifying and testing method for high speed train

A high-speed EMU and testing method technology, applied in the field of rail transit, can solve the problems of inability to identify the noise source of the high-speed EMU, inability to realize vibration and noise source control and path control in the vehicle, and inability to analyze the contribution of noise sources, etc., to achieve The effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

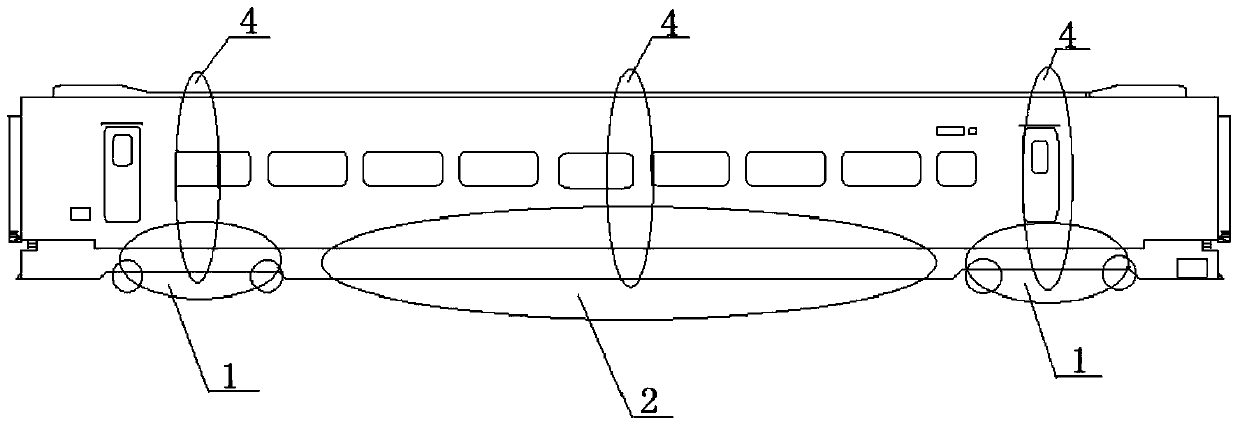

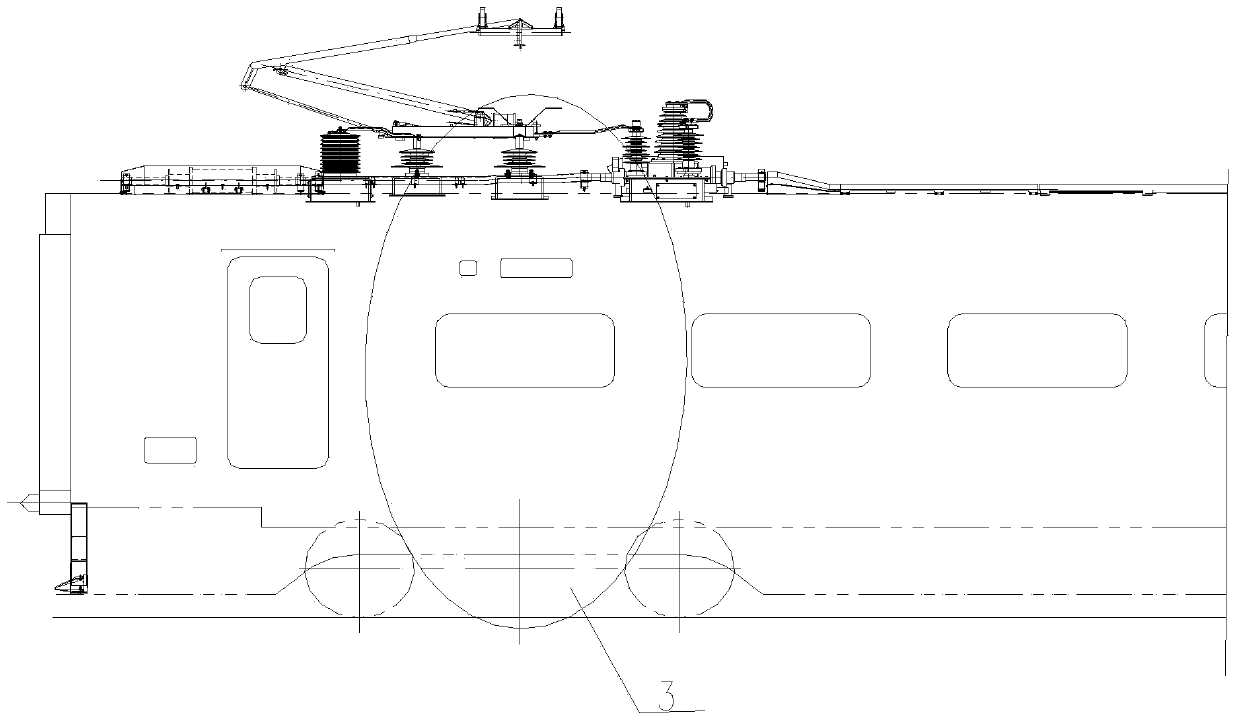

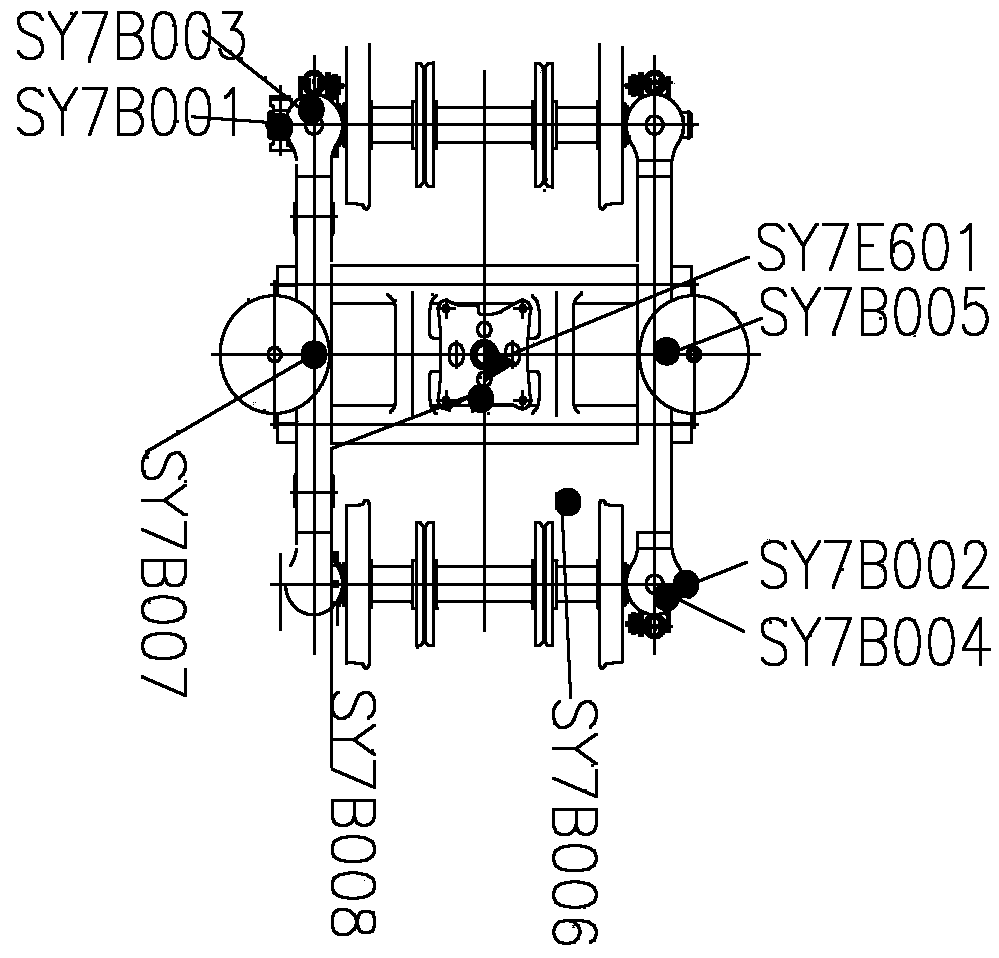

[0041] like figure 1 and figure 2 As shown, a kind of high-speed EMU noise source identification test method provided by the present invention is based on the noise source, and according to the distribution and propagation characteristics of the high-speed EMU noise source, the noise source identification test of the high-speed train is divided into four tests The areas are bogie wheel-rail noise test area 1, equipment room noise test area 2, pantograph noise test area 3 and aerodynamic noise test area 4.

[0042] Among them, for the test of aerodynamic noise test area 4, the aerodynamic noise mainly comes from the interaction between the air and the surface of the high-speed train body, which is distributed on the entire surface of the high-speed train body. Quantity limitation cannot cover the entire car body surface, and because the noise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com