A downhole light source drilling system

A light source and drilling technology, applied in the automatic control system of drilling, drilling equipment, application of thermal energy drilling, etc., can solve the problems of complex downhole environment adaptability of downhole light source, achieve compact structure, expand application scope, and improve the effect of output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

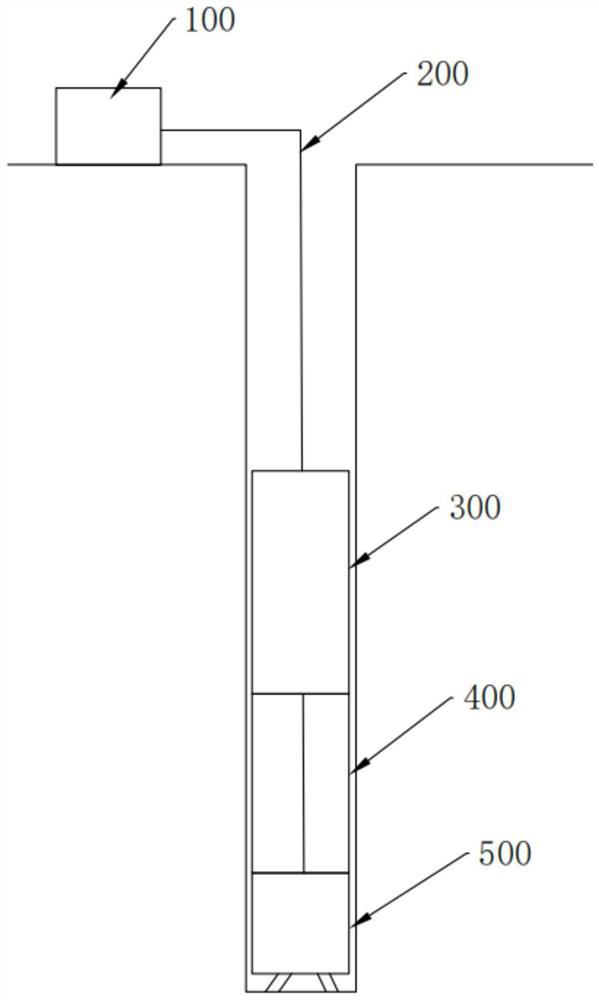

[0034] A downhole light source drilling system, such as figure 1 As shown, it includes an external power supply, a transmission cable 200, a downhole light source 300 arranged downhole for emitting laser beams to the downhole working face, a laser drill collar 400 and a laser drill bit 500 arranged in sequence along the laser beam emission direction, and the external power supply passes through The transmission cable 200 is connected with the downhole light source 300 , the laser drill collar 400 and the laser drill bit 500 .

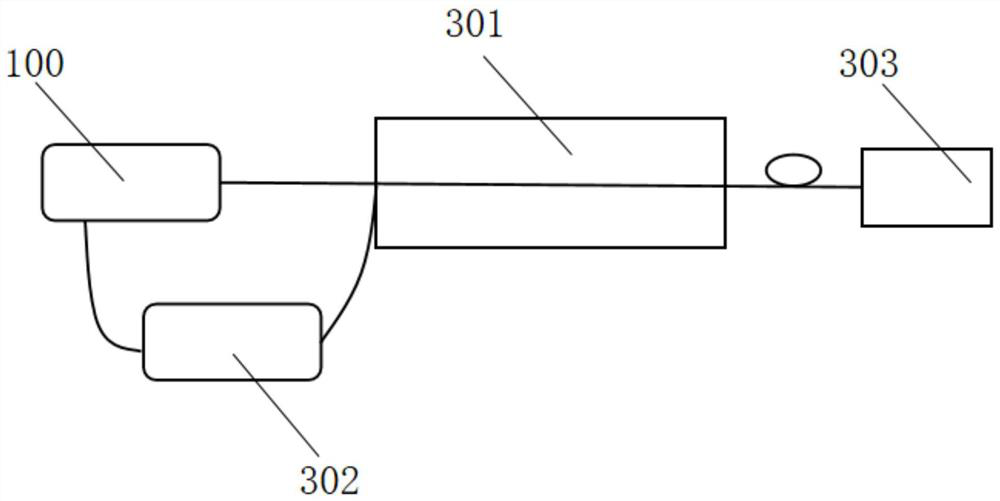

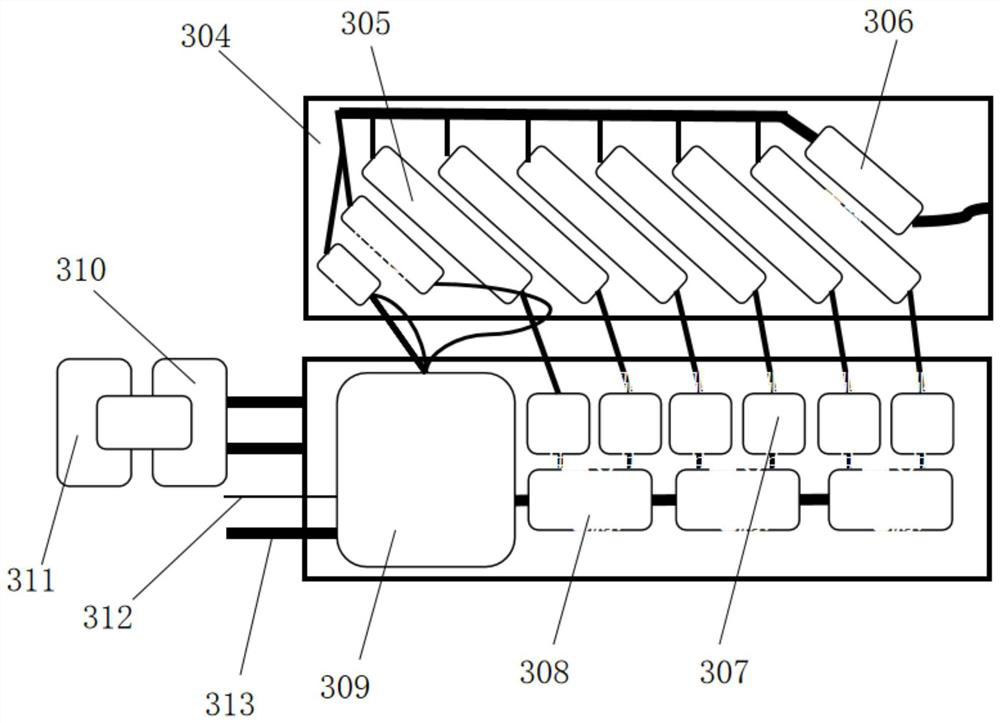

[0035] According to the miniaturization and high-efficiency requirements of the downhole light source, the downhole light source 300 adopts the method of optical fiber coupling and beam combining of semiconductor lasers, specifically, as figure 2 and image 3As shown, the downhole light source 300 includes an optical module, a driving module 307 and a temperature control module 302, wherein the optical module and the driving module 307 are packaged in...

Embodiment 2

[0044] like Figure 4 As shown, the same part of this embodiment and embodiment 1 will not be repeated, and the difference is:

[0045] In this embodiment, there are 3 groups of cascaded laser groups 314, and each group of cascaded laser groups 314 includes 5 sub-lasers 305 and 1 laser emitting indicating red light. The sub-lasers 305 located in the same group are combined through the first fiber combiner 306 to form the first combined laser beam, and the cascaded laser groups 314 are combined through the second fiber combiner 315 to form the second beam The second combined laser beam is used as an output beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com