Combinatorial testing accessory of vibration testing platform and static fatigue testing method

A vibration test bench and combined testing technology, which is applied in vibration testing, testing of material strength by applying repetitive force/pulsation force, testing of machine/structural components, etc., can solve the problem of low frequency of fatigue testing machine, single testing method and vibration fatigue And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

[0092] Embodiment (one): the combined test accessory for vibration test bench, such as Figure 1-18 shown.

[0093] Take the ET-10d-240 electric vibration test bench as an example, the span of the vibration test bench L=980mm, and the diameter of the vibration test bench D=240mm. According to this type of electric vibration test bench, the combined accessories are designed, and all accessories are made of 42CrMo steel, which is made by forging, quenching and tempering and machining.

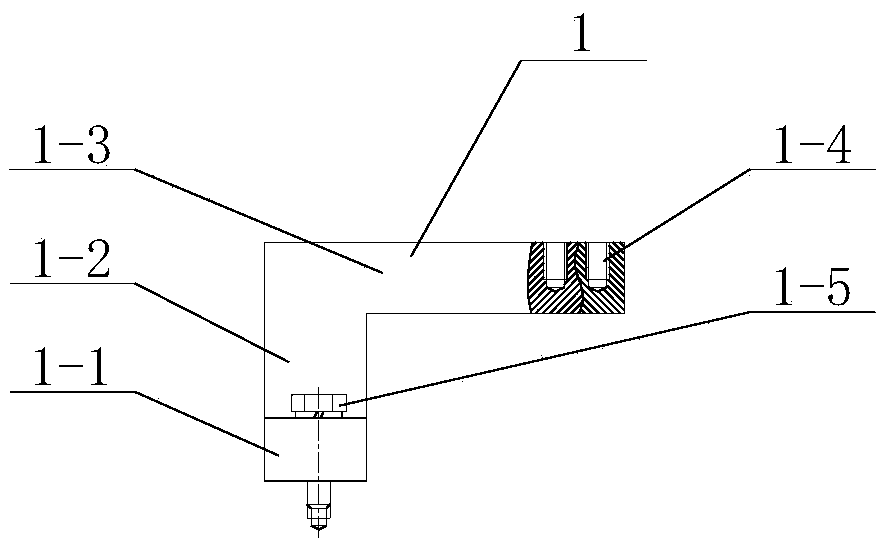

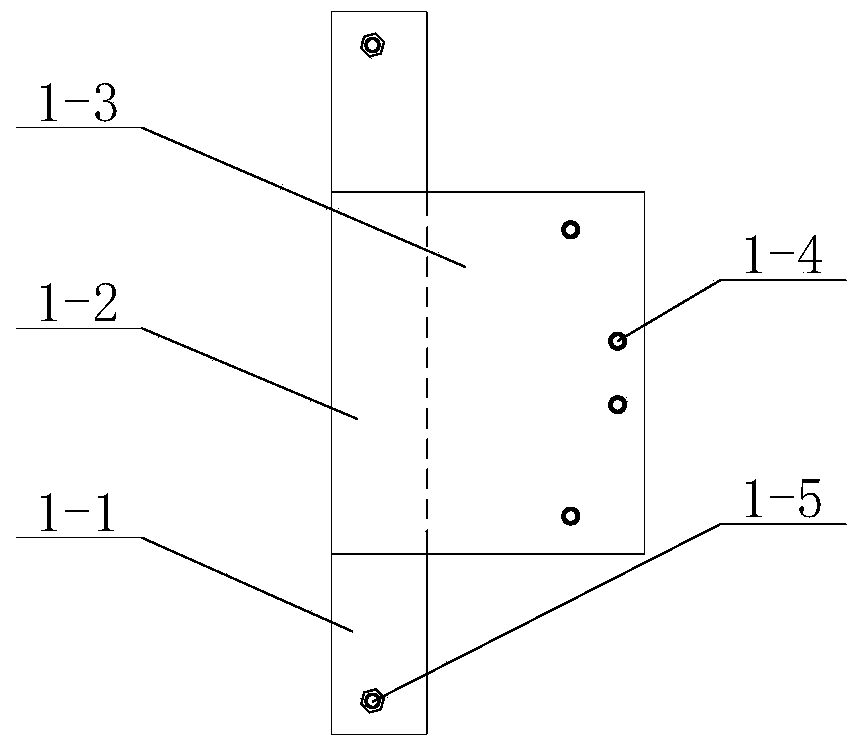

[0094] 1. Support bracket

[0095] Such as figure 1 , figure 2 As shown, the support bracket 1 is composed of a base 1-1, a bracket leg 1-2, a bracket arm 1-3, a threaded hole 1-4 and a fastening bolt 1-5; the bracket leg 1-2 is 300mm wide, 150mm high, The thickness is 20mm; the bracket arm 1-3 is 300mm long, 300mm wide, and 20mm thick, and the free end of the arm is symmetrically drilled with 4 M10 threaded holes 1-4 along the width direction; the base 1-1 is 600mm long, 100mm wide, and 20m...

Embodiment

[0107] Embodiment (two): bending fatigue test, such as Figure 19 ~ Figure 27 shown.

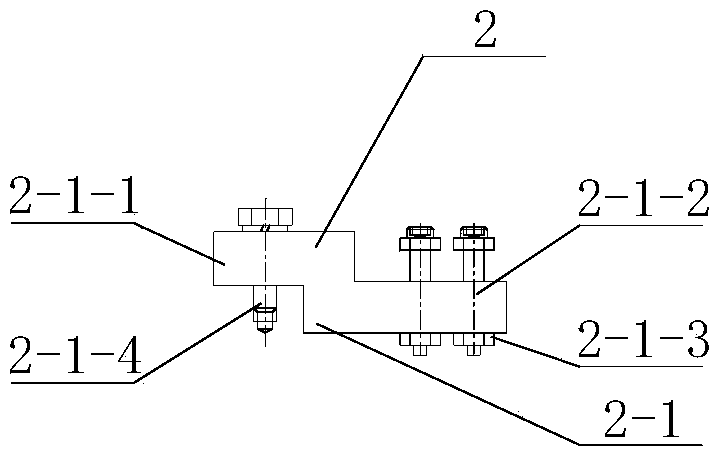

[0108] 1. If Figure 19 , Figure 20 As shown, the cantilever bending fatigue test consists of a support bracket 1, a fixed sample holder 2-1, a simply supported vibration sensor 3-1, a vibration test bench frame 5, and a vibration test bench table 6 , Sample 7; the sample is a strip plate, one end of which is a clamping end with a bolt hole, and the clamping end can be wider than the non-clamping part.

[0109] Before the test starts, the base 1-1 of the support bracket 1 is installed on the vibration test bench frame 5 through the fastening bolt 1-5; the connection end 2-1-1 of the fixed support sample holder 2-1 Install on the support arm 1-3 of the support bracket 1 through the fastening bolt 2-1-4; install the base 3-1-1 of the simply supported vibration sensor 3-1 on the support arm 1-3 through the fastening bolt 3-1-5 On the table 6 of the vibration test bench, and keep the three ...

Embodiment ( 4

[0125] Embodiment (four): tension-pull or tension-compression fatigue test, such as Figure 32 shown.

[0126] The tension-pull or tension-compression fatigue test consists of 2 support brackets 1, 1 follower sample holder 2-4, 1 fixed support vibration transmitter 3-3, 1 bridging bracket 4, vibration test bench Frame 5, vibration test bench top 6, and sample 7; the sample is a strip plate, and both ends of the strip plate are clamping ends with bolt holes.

[0127] Before the start of the test, install the bases 1-1 of the two supporting brackets 1 on the vibration test bench frame 5 on both sides through fastening bolts 1-5, and fasten the base 4-1 of the bridging bracket 4 through the fastening bolts 1-5. Bolts 4-6 are installed on the bracket arms 1-3 of the two supporting brackets 1, and the base 3-3-1 of the fixed-supported vibration transmitter 3-3 is installed on the vibration test bench by fastening the bolts 3-3-4 On the table top 6; the follow-up sample holder 2-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com