Patents

Literature

35 results about "Joint loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

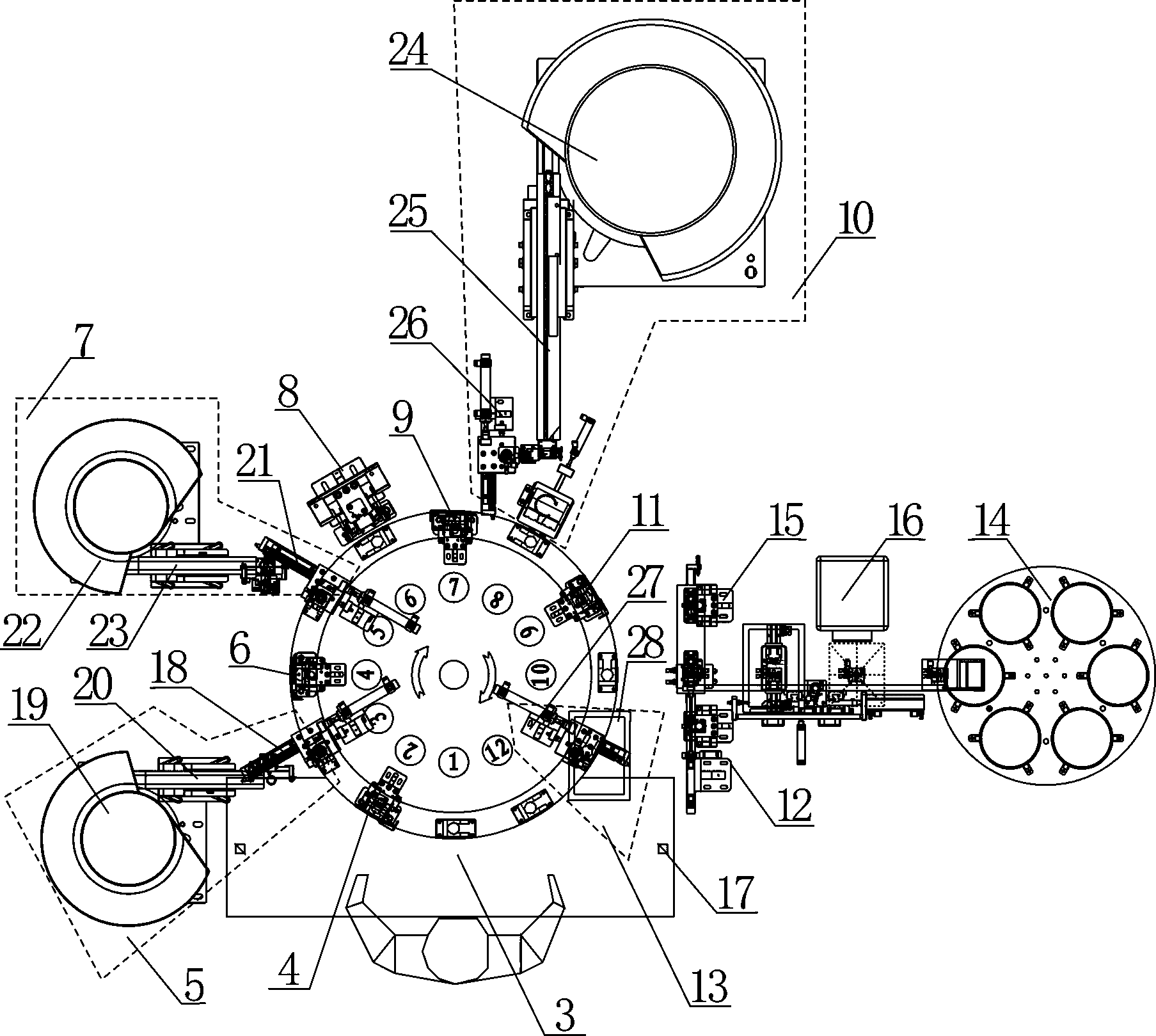

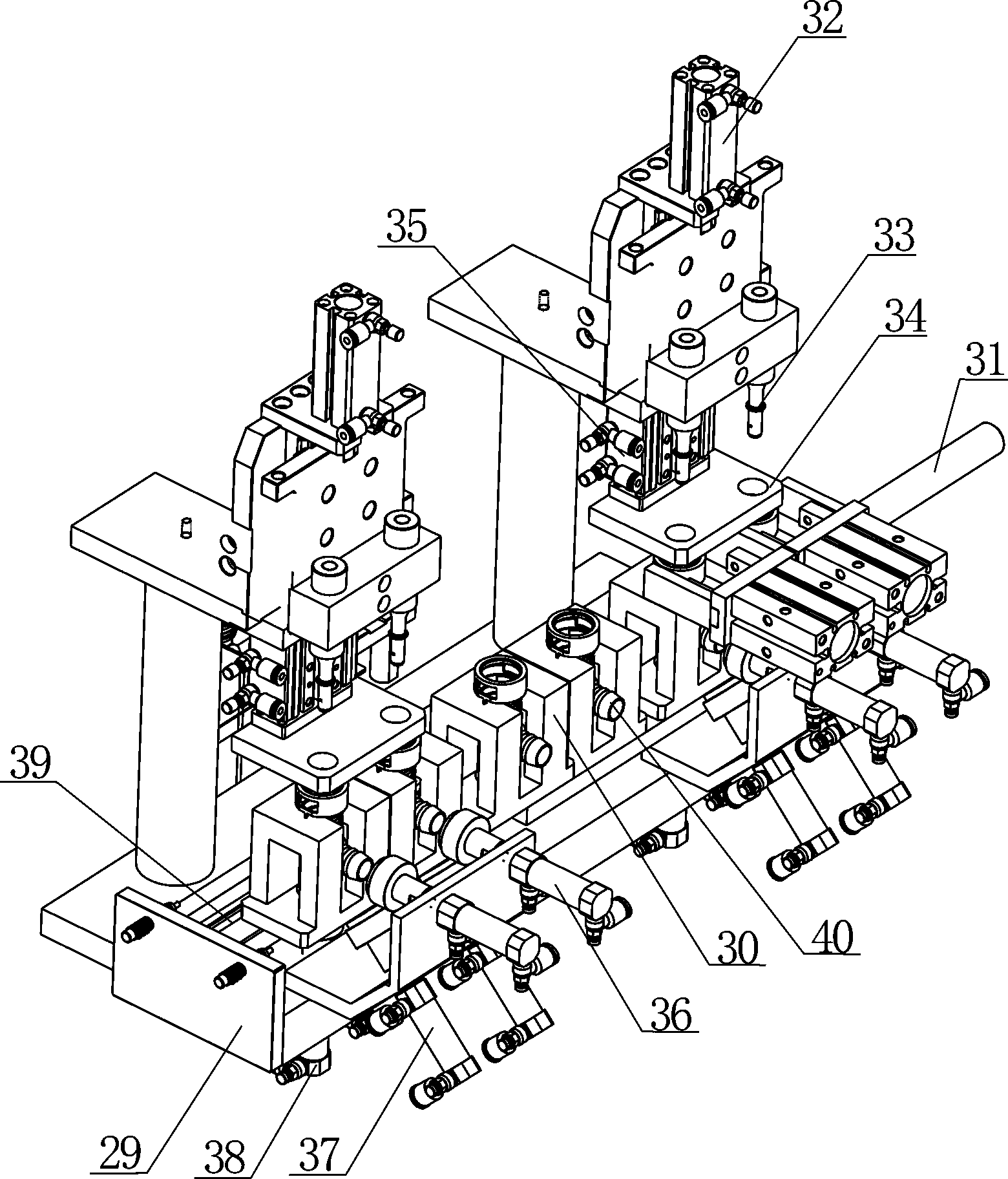

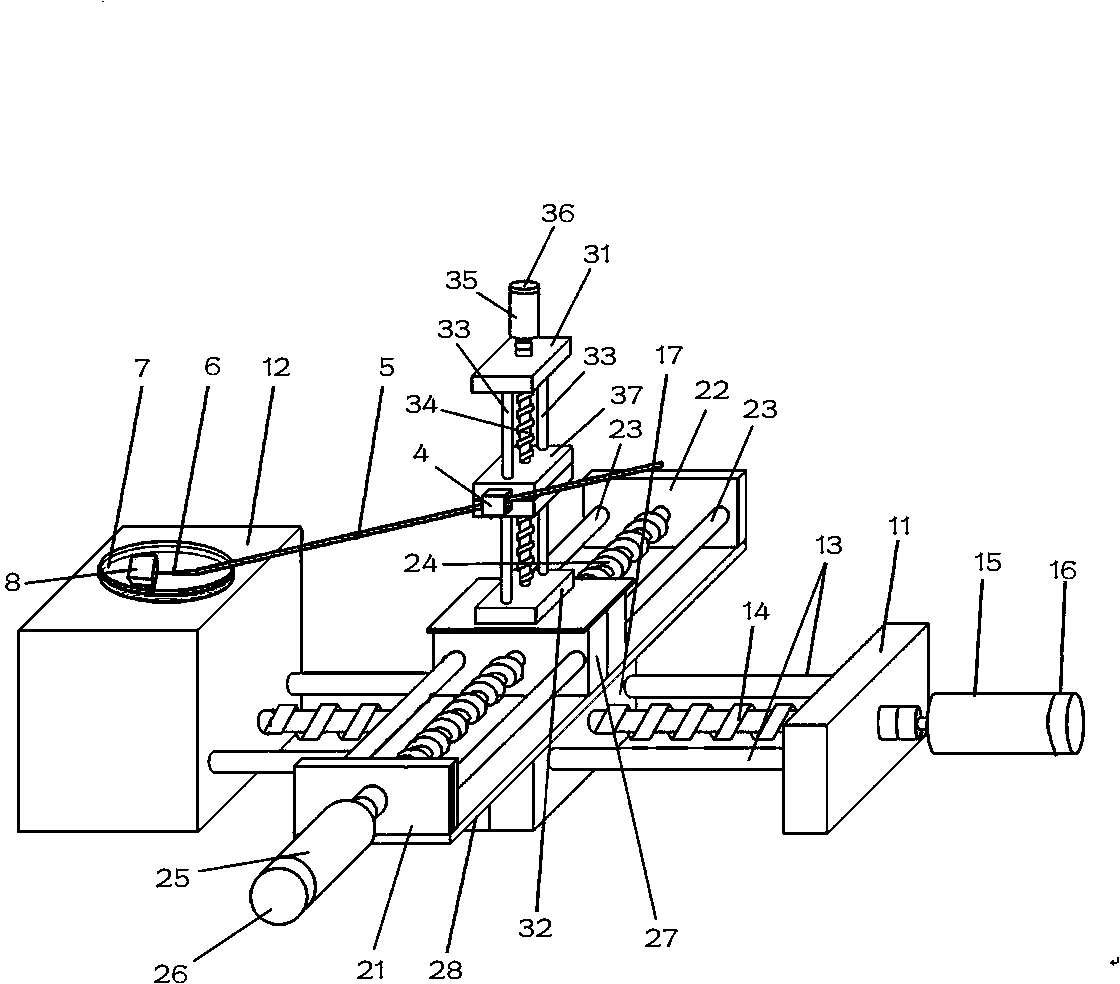

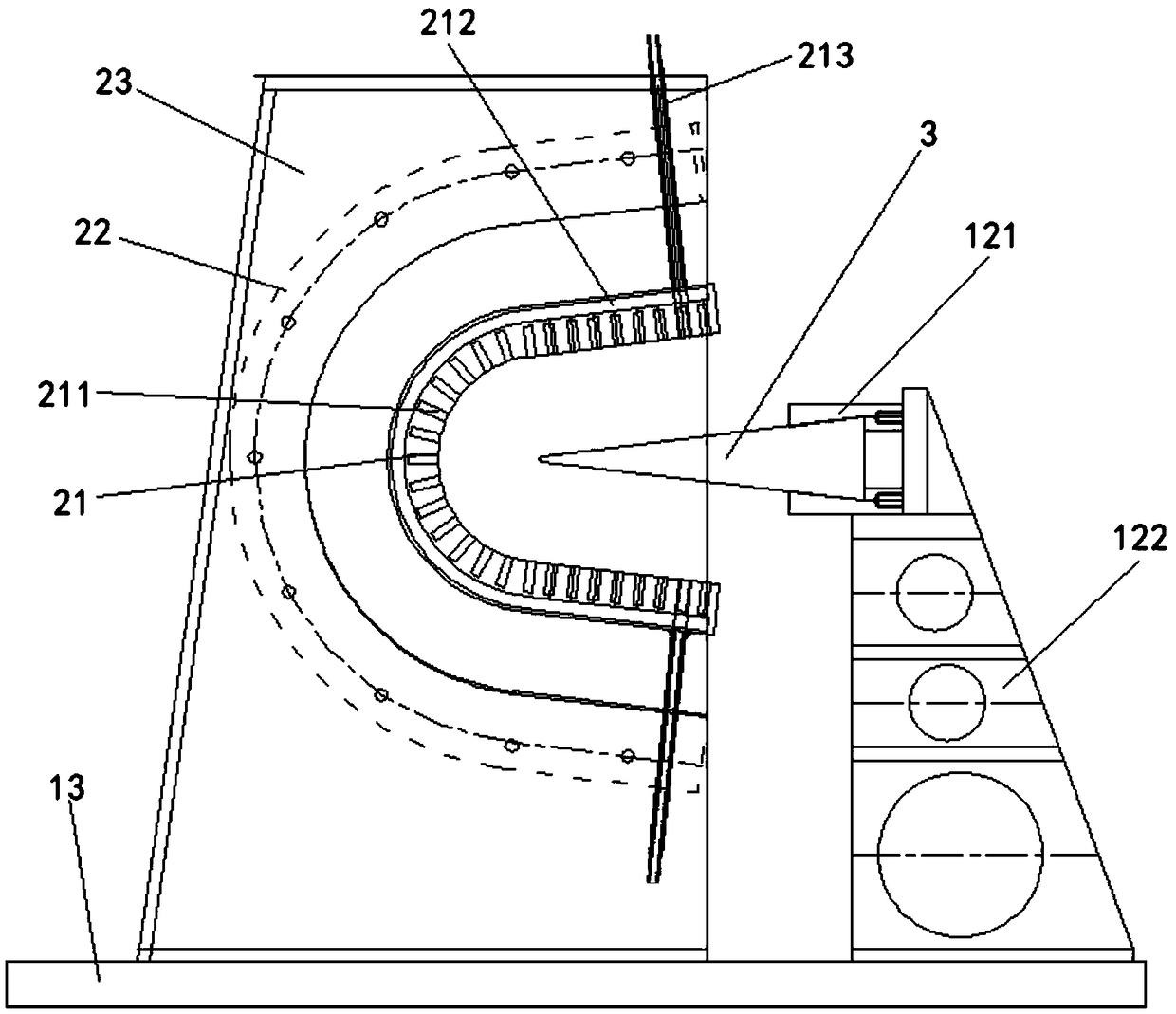

Assembling machine for multiple types of pipe joints

ActiveCN103753208ARealize the assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusForeign matterManipulator

The invention discloses an assembling machine for multiple types of pipe joints. The assembling machine comprises an intermittent rotating disc. Twelve jigs are evenly distributed on the intermittent rotating disc along the periphery thereof at intervals. A manual pipe-joint loading station, a foreign-matter detecting device, a seal-ring loading device, a seal-ring on-line measuring device, a safety-ring loading device, a safety-ring pressing device, a safety-ring pressing detecting device, a locking-spring loading device, a locking-spring loading detecting device, a multi-grasping manipulator and an assembled-rejects taking device are sequentially arranged around the intermittent rotating disc according to successive working procedures. An airtightness detecting device, a laser coding machine and a packing rotating disc are sequentially arranged on one side of the multi-grasping manipulator. As being provided with an 90-degree pipe-joint plugging air cylinder, a 135-degree pipe-joint plugging air cylinder and a straight-pipe-joint plugging air cylinder, the airtightness detecting device can detect 90-degree pipe joints, 135-degree pipe joints and straight pipe joints, so that the assembling machine can assemble various types of pipe joints.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

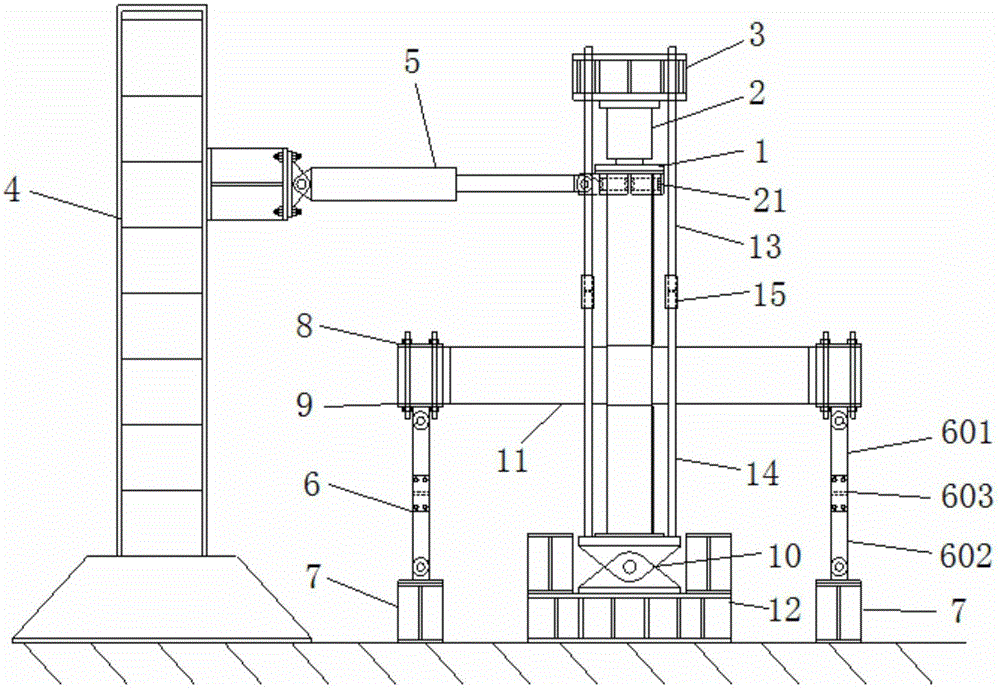

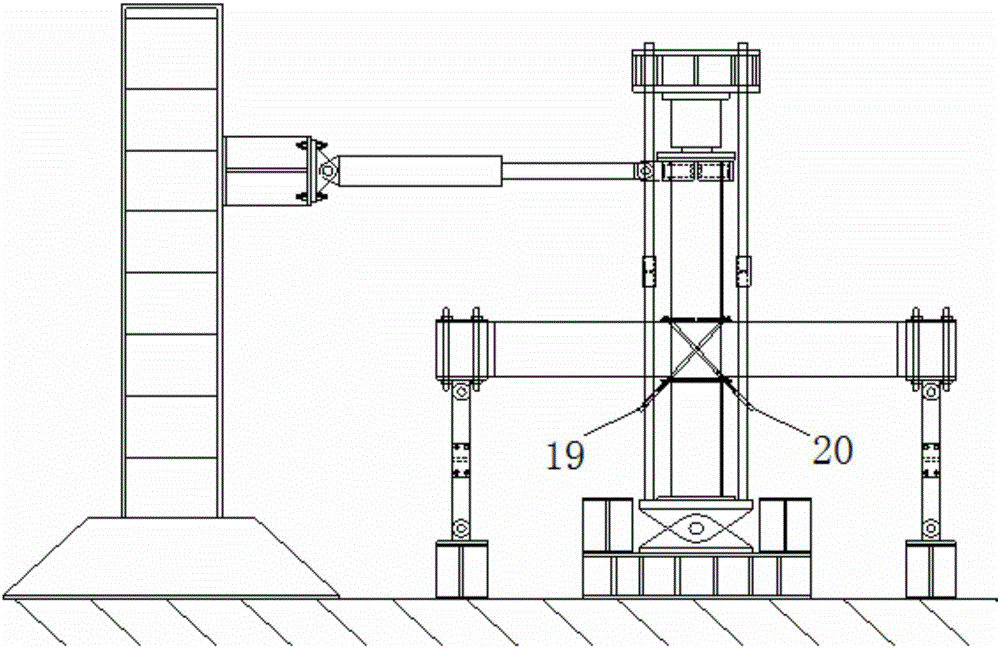

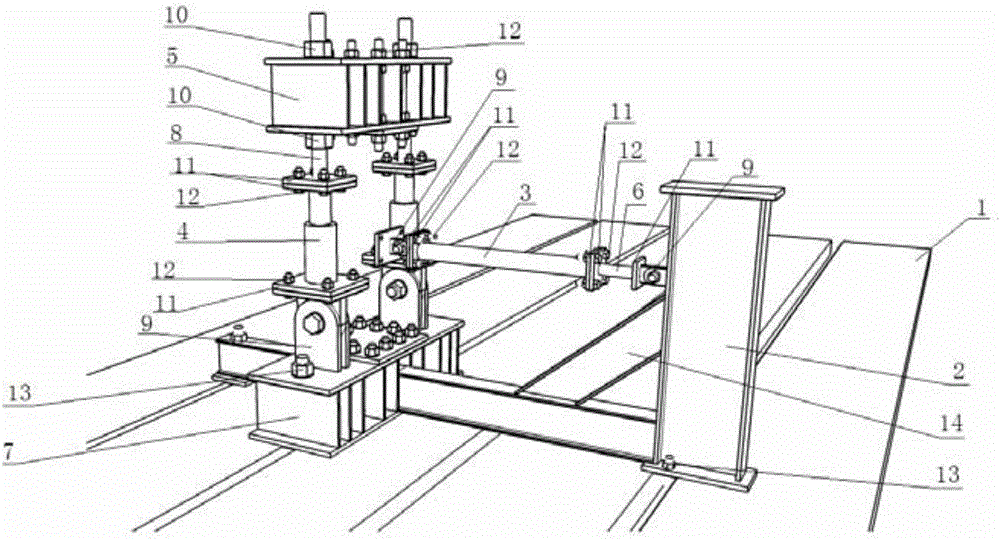

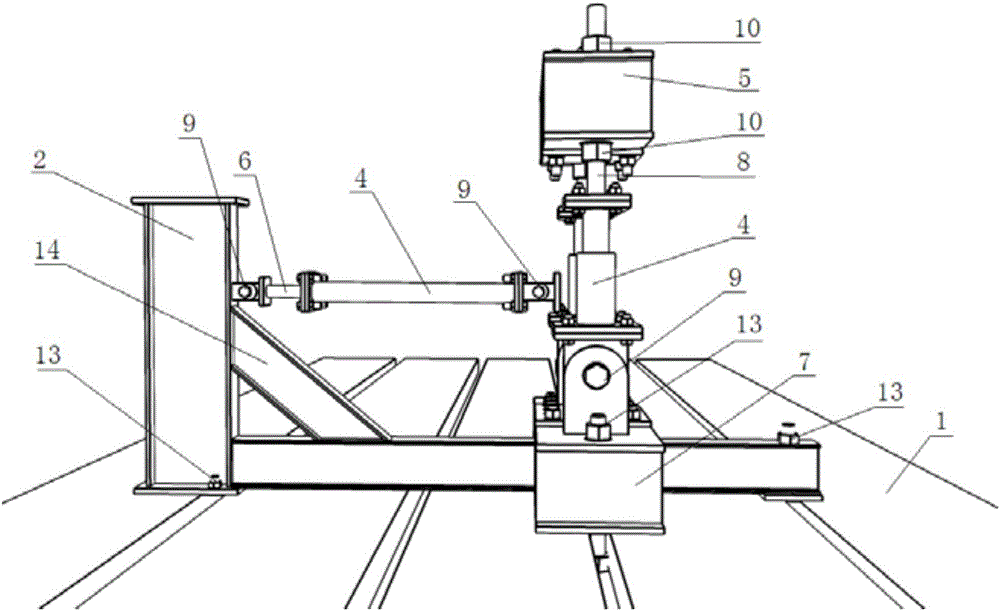

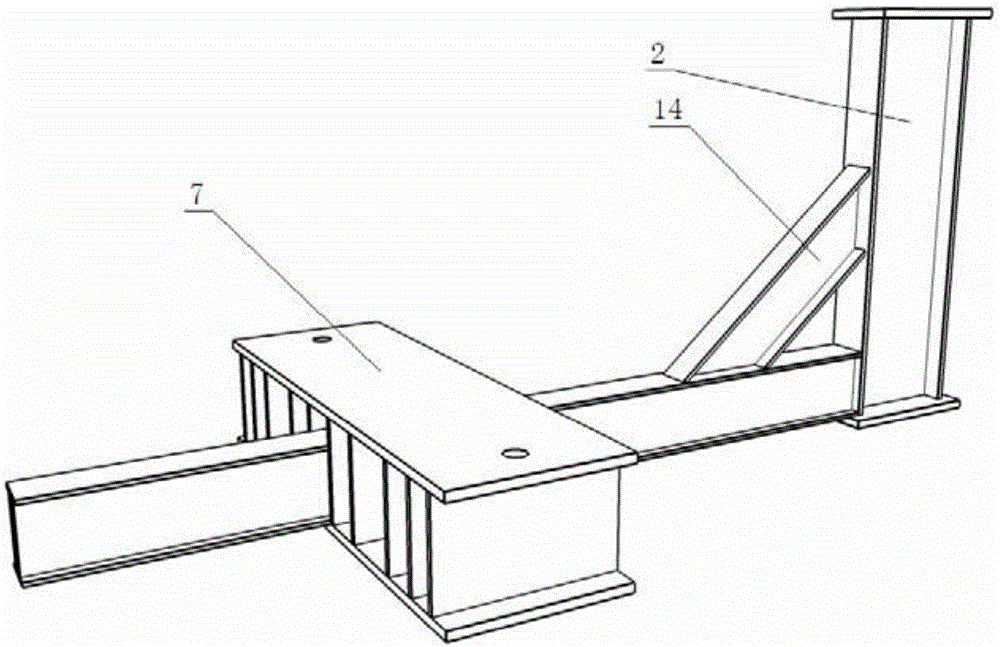

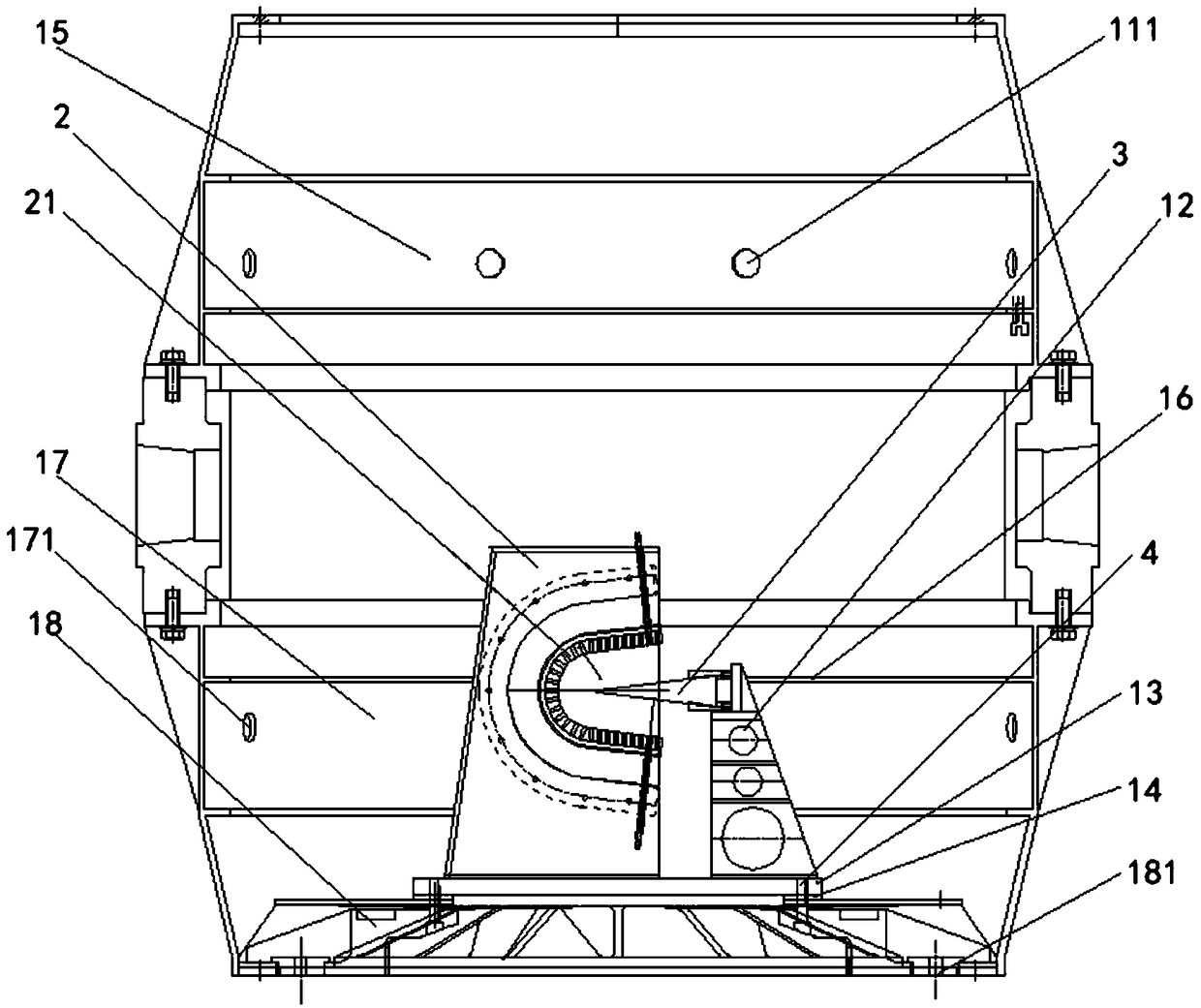

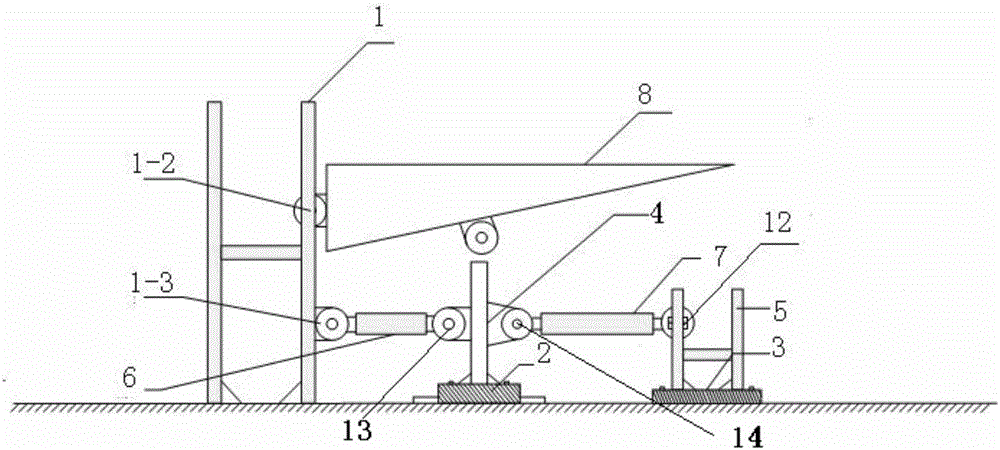

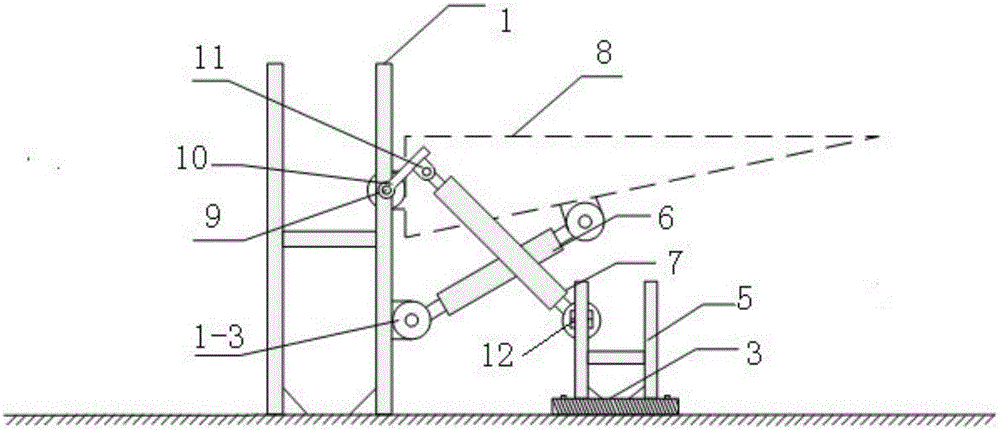

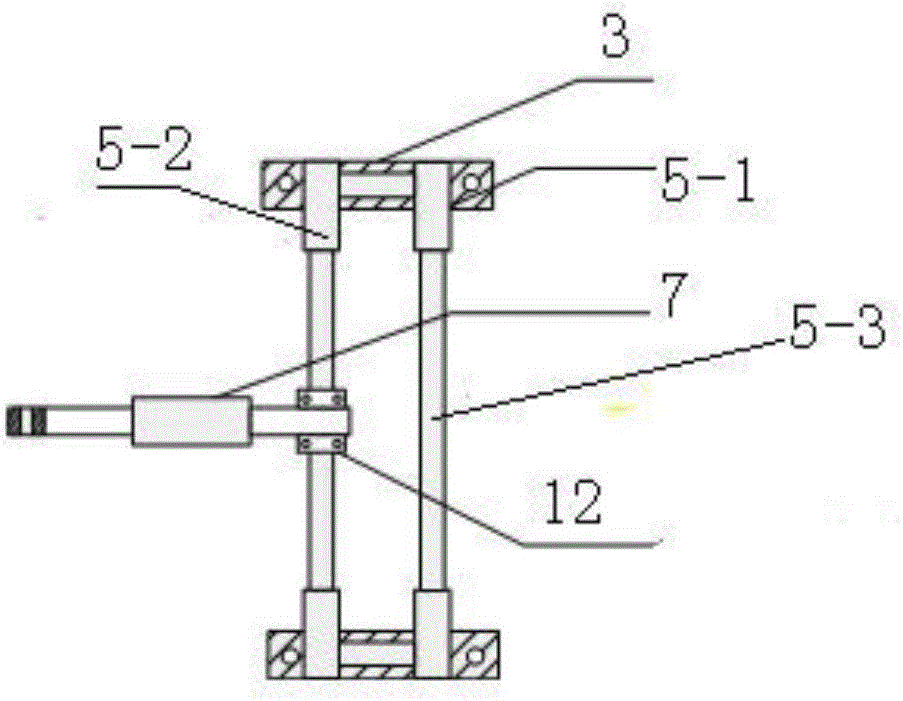

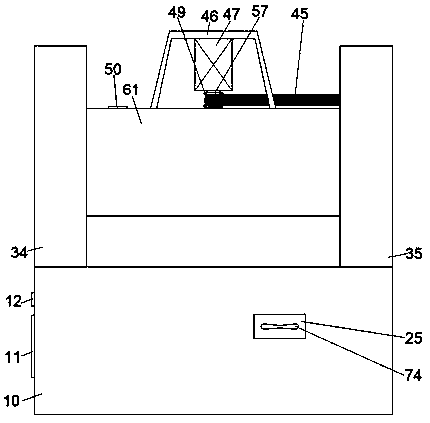

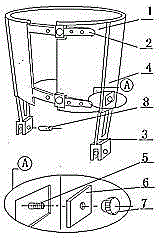

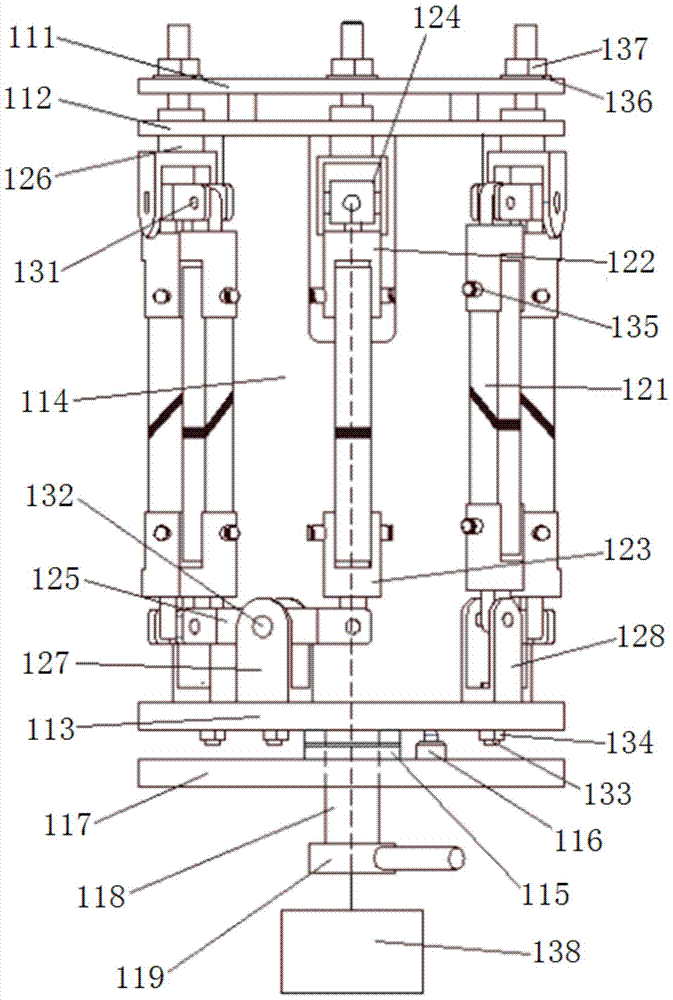

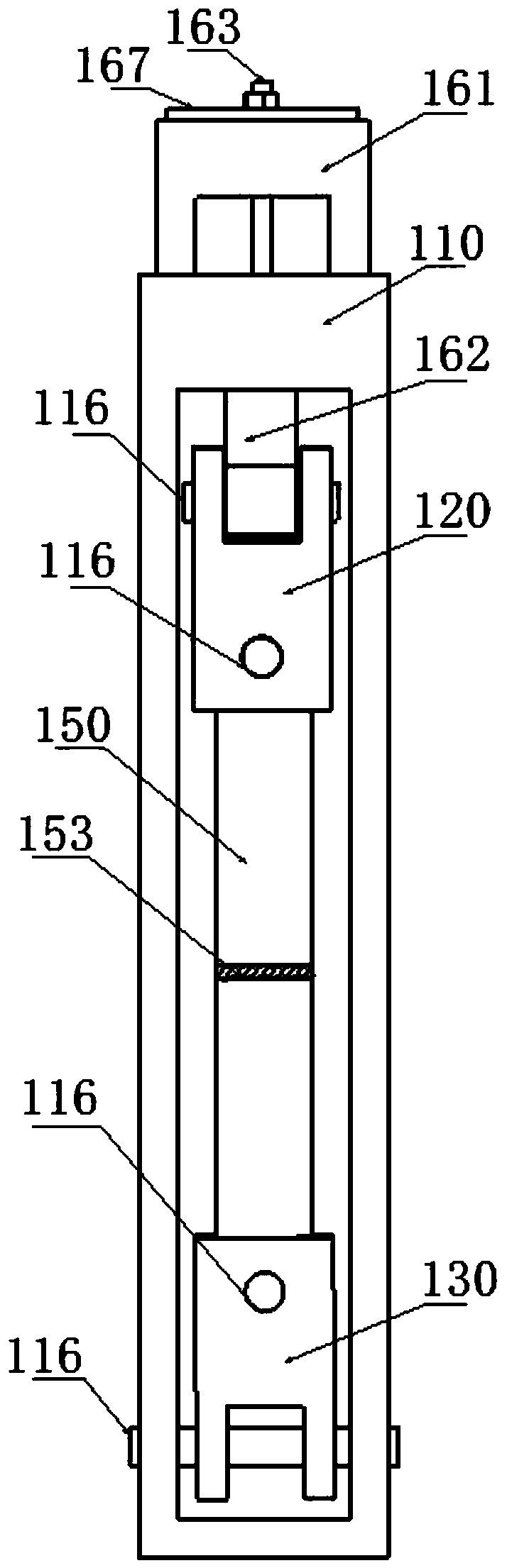

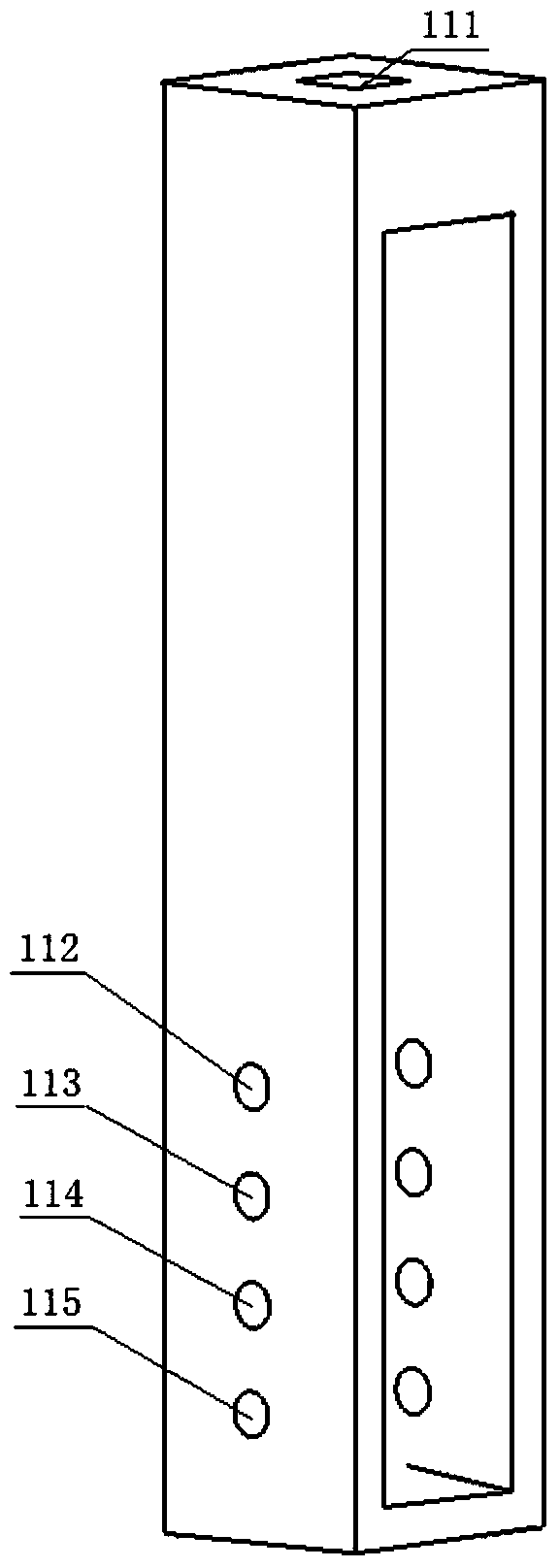

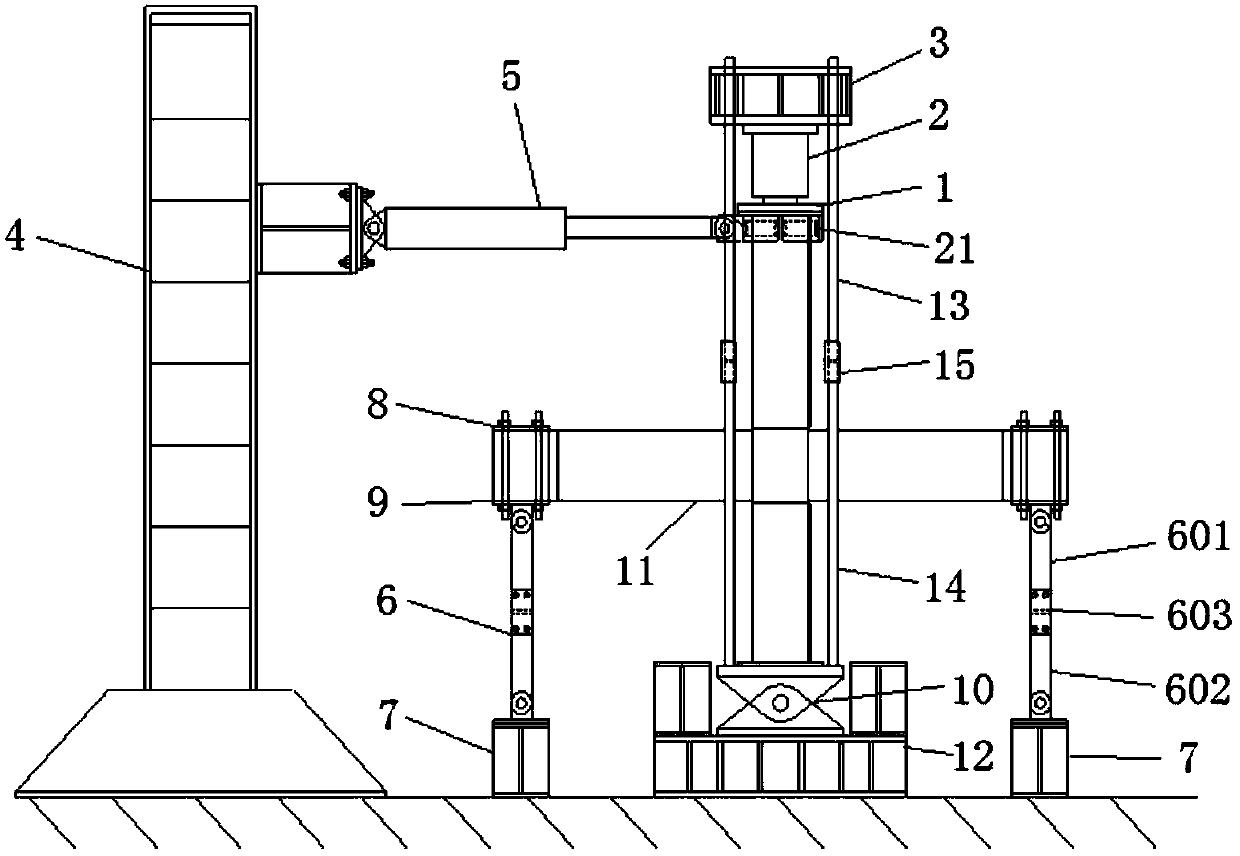

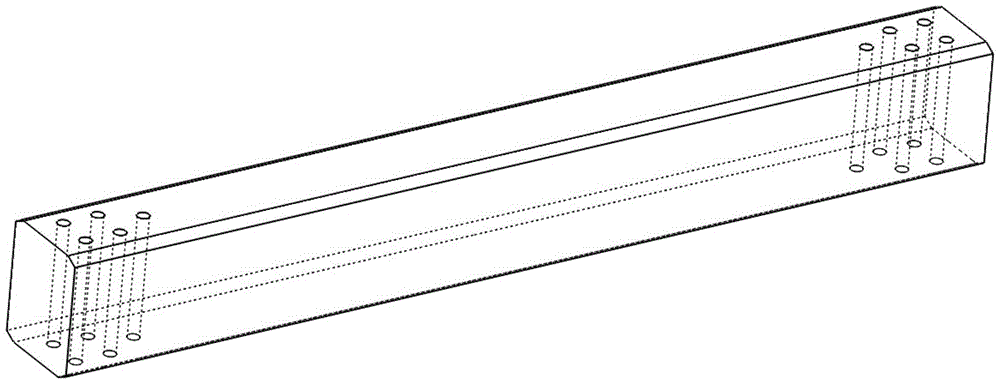

Planar frame joint loading and joint region shear deformation measuring device

ActiveCN106153314AEasy to installPrevent twistingMachine part testingEngineeringShearing deformation

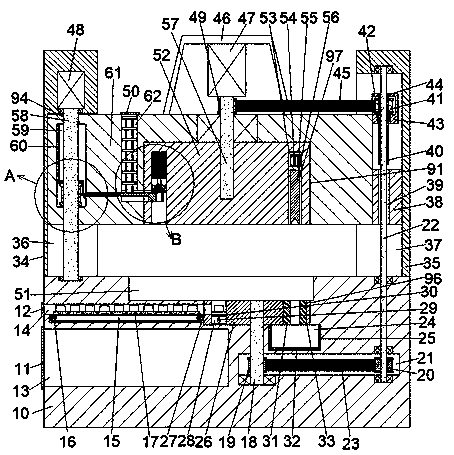

The invention provides a planar frame joint loading and joint region shear deformation measuring device. The planar frame joint loading and joint region shear deformation measuring device comprises an axial self-balancing reaction frame, a horizontal loading reaction frame and two-force pole supporting frames. An axial force is applied to a joint test-piece through the axial self-balancing reaction frame until the axial force achieves a preset value; the two-force pole supporting frames are symmetrically arranged at two ends of the cross beam of the joint test-piece and are hingedly connected with the cross beam and support the cross beam firmly; and the horizontal loading reaction frame, adopted as a loading device, provides a lateral loading force for the joint test-piece, so that the joint test-piece can go through shear deformation. According to the planar frame joint loading and the joint region shear deformation measuring device of the invention, the axial force is applied through a self-balancing manner, so that error caused by the application of a large axial force by adopting a traditional joint device or an MTS or a jack can be eliminated. Compared with a traditional joint loading device, the planar frame joint loading and joint region shear deformation measuring device has the advantages of easier implementation, convenience in the control of column end loading, high test precision and small occupied space, and can be used for performance testing of joints in a plane and edge joints, and is especially applicable to seismic performance testing of various kinds of joints of planar frames.

Owner:CHONGQING UNIV

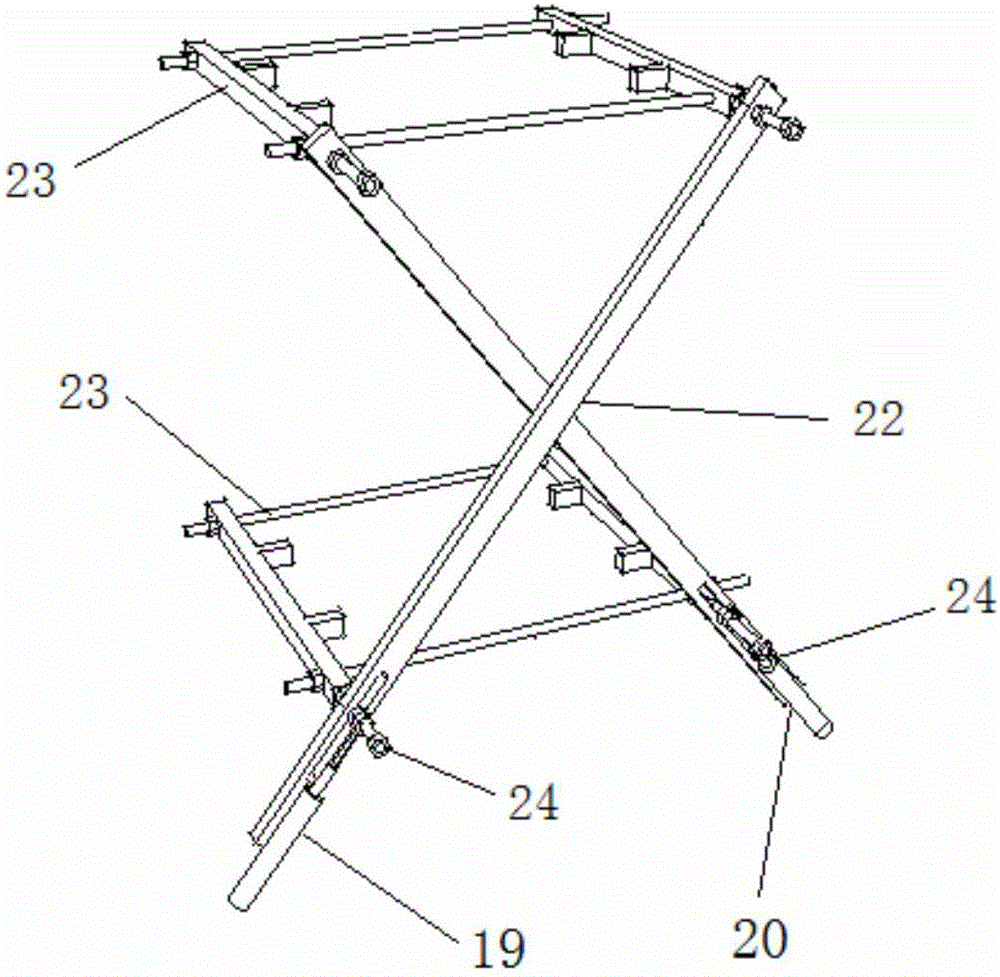

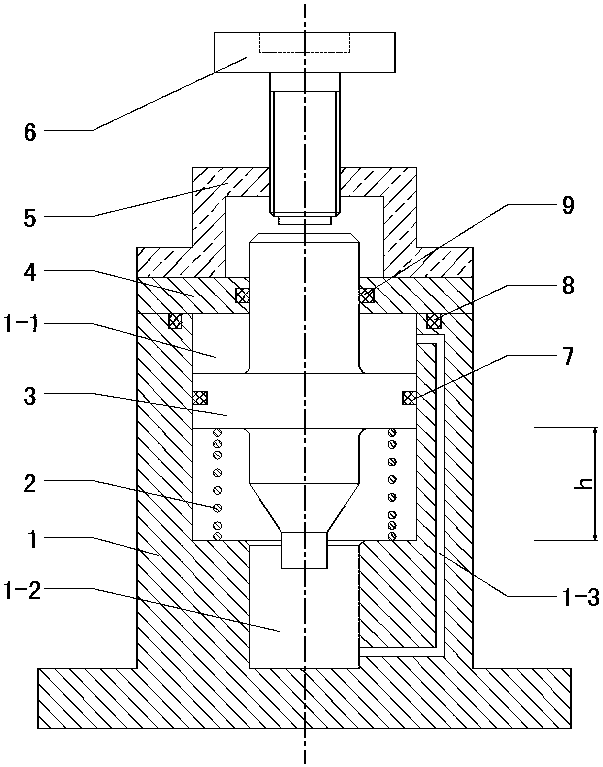

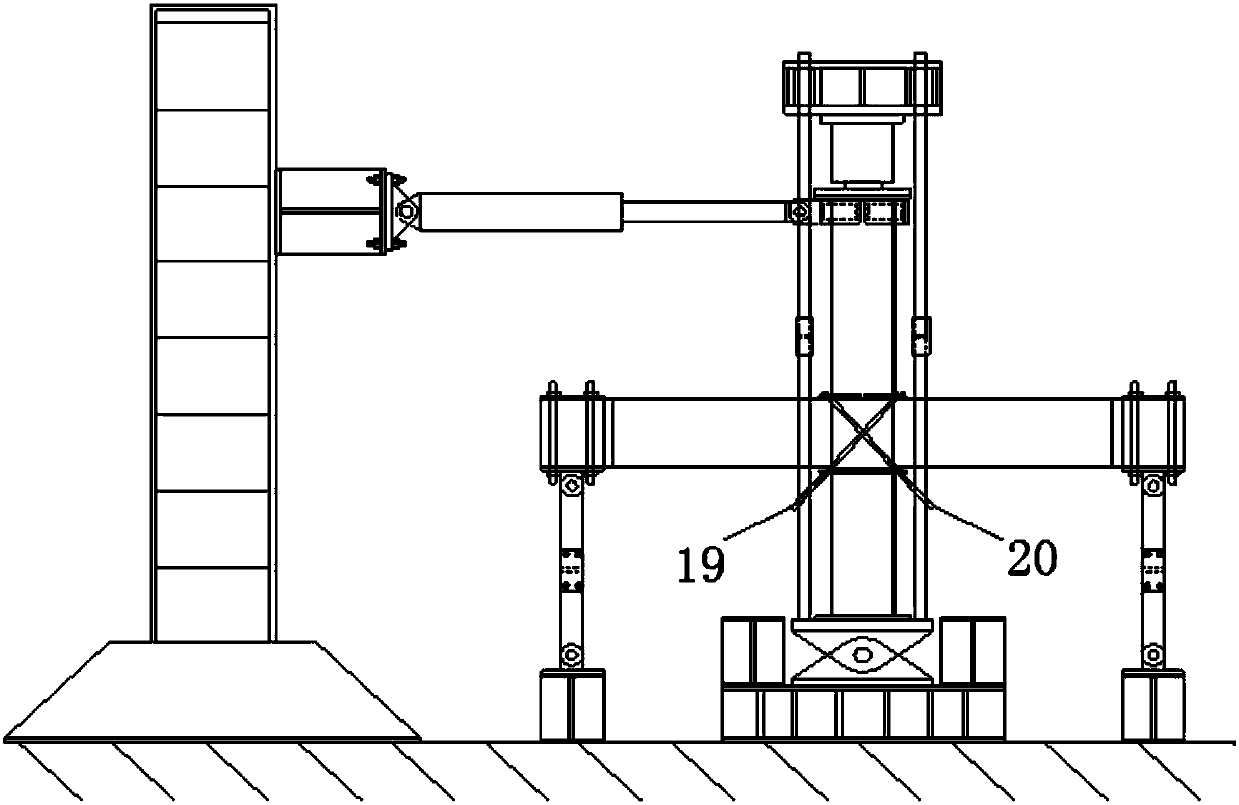

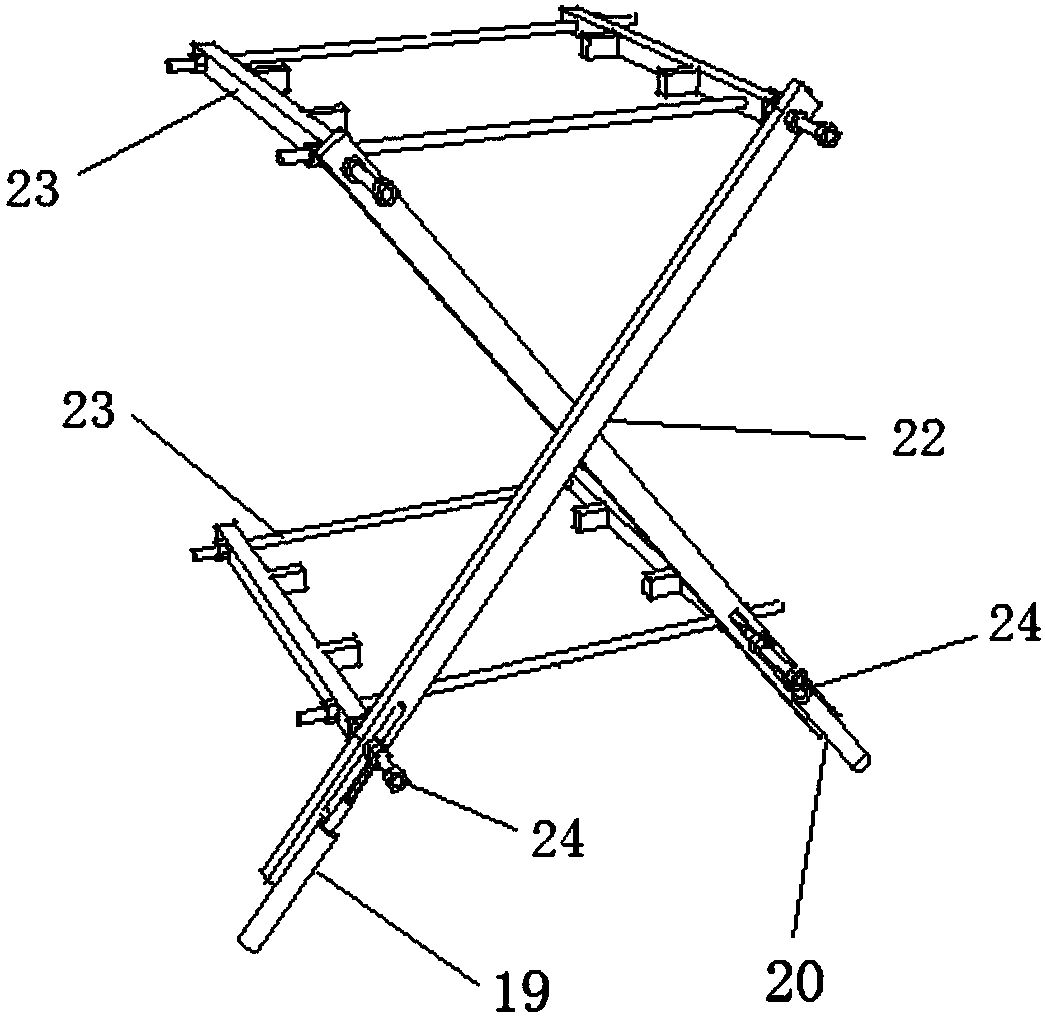

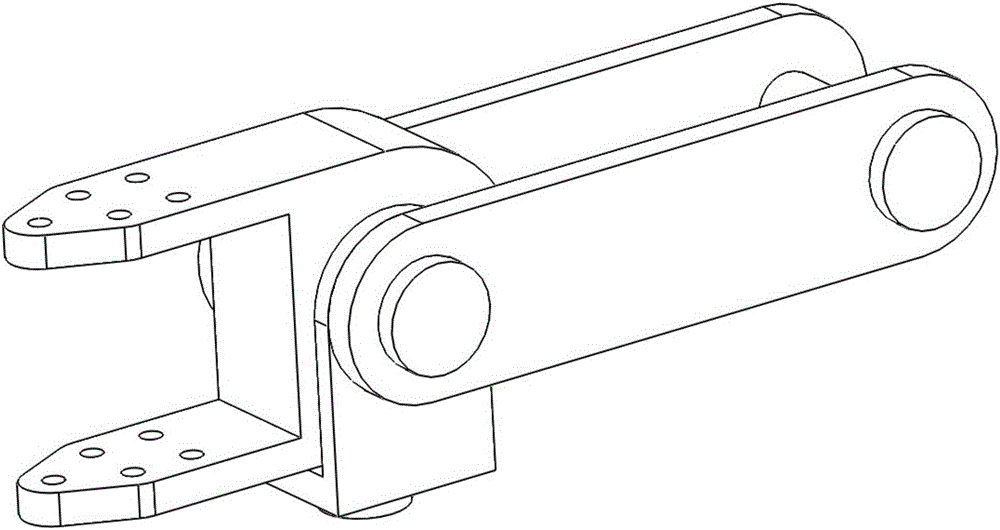

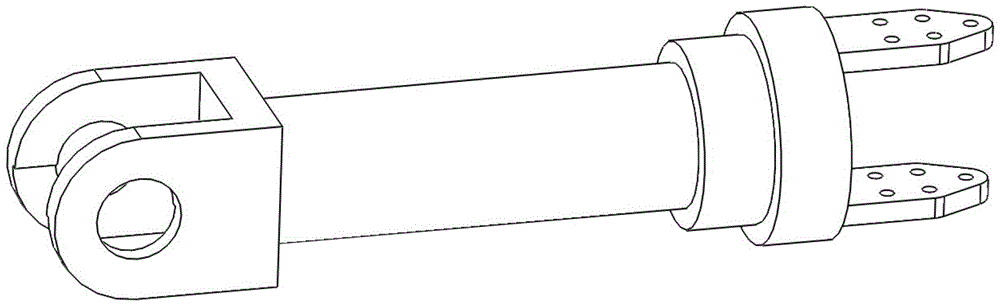

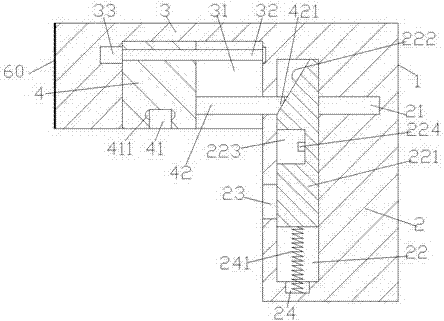

Loading device used for space fabricated type semi-rigid joint test

PendingCN106596251AUniform tensionAvoid constraintsMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesEngineeringAxial force

The invention discloses a loading device used for a space fabricated type semi-rigid joint test, and relates to test loading devices. The invention aims at solving the problems that an existing loading test can only be conducted through a traditional force loading machine and simultaneous loading of axial force and bending moment can not be achieved. The loading device for the space fabricated type semi-rigid joint test comprises an L-shaped counter-force support, a horizontal hydraulic jack, a fixed support, a counter-force beam and two vertical hydraulic jacks, wherein the fixed support is vertically and fixedly connected to a horizontal end of the L-shaped counter-force support, the upper end of the fixed support is provided with the counter-force beam, the two vertical hydraulic jacks are arranged between the fixed support and the counter-force beam in a parallel mode, the lower ends of the vertical hydraulic jacks are rotationally connected to the upper end face of the fixed support through an articulated mechanism, anchor bolts are fixedly connected to the upper ends of the vertical hydraulic jacks, and the upper ends of the anchor bolts are fixedly connected to the counter-force beam, the inner side of the vertical end of the L-shaped counter-force support is vertically provided with the horizontal hydraulic jack, and the front end of the horizontal hydraulic jack is rotationally connected to the L-shaped counter-force support through the articulated mechanism. The loading device used for the space fabricated type semi-rigid joint test is used for joint loading tests.

Owner:HARBIN INST OF TECH

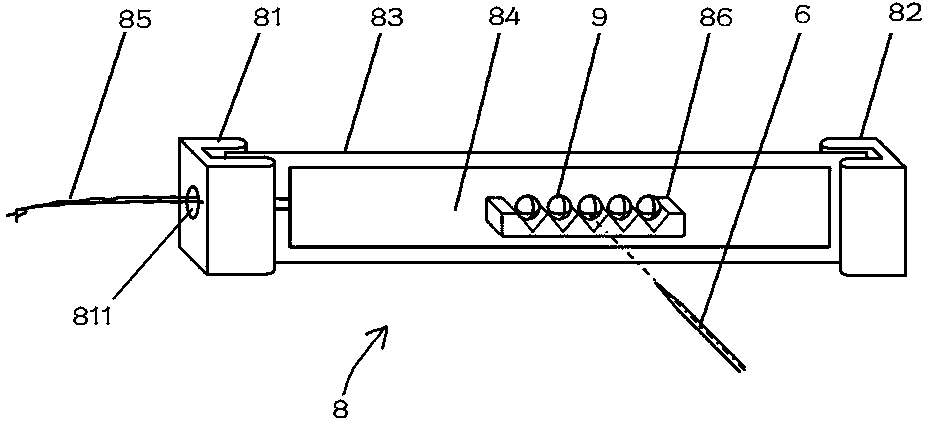

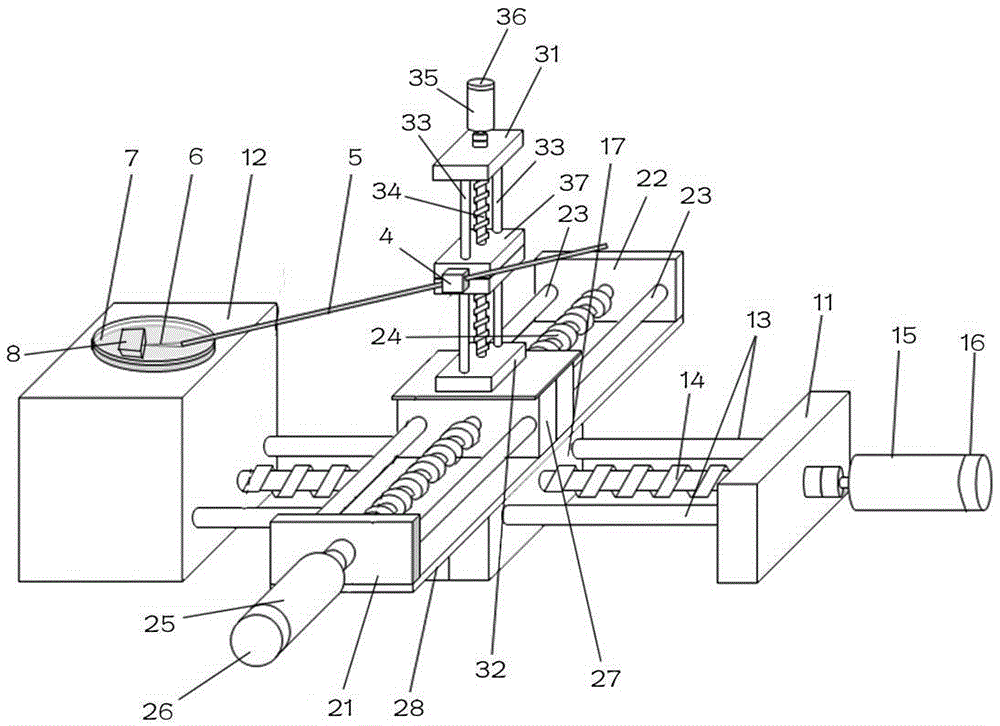

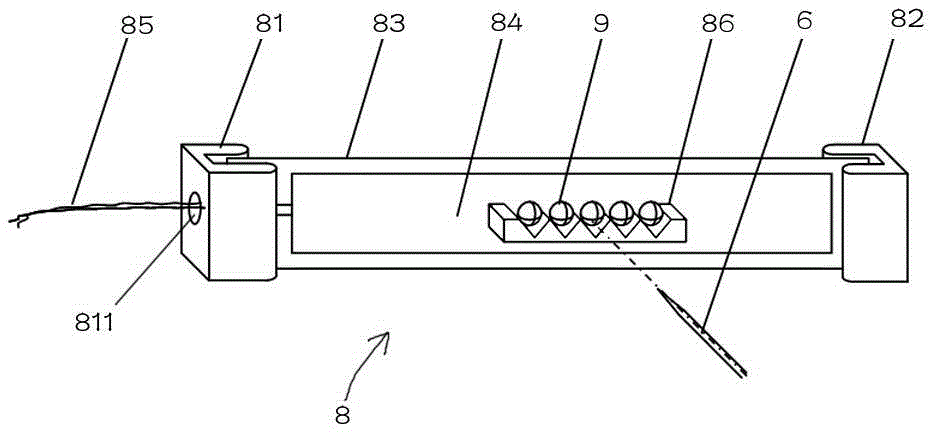

Devices for cell composite force-electric load measurement

InactiveCN103966091AImplement continuous loadingRealize the loadStress based microorganism growth stimulationElectricityControl system

The invention belongs to the technical field of cell engineering, and particularly relates to a cytomechanic-electrical joint loading and analyzing device in a biomedical experimental instrument. The invention discloses a device for cell composite force-electric load measurement. The device comprises a mechanical drive system, a mechanical drive control system, an electrode probe, a cell placement platform, an electric signal generation system and a piezoelectric measurement system. The invention also discloses a device for cell composite force-electric load measurement. The device for cell composite force-electric load measurement comprises a mechanical drive system, a mechanical drive control system, an electrode probe, a cell placement platform, an electric signal measuring system and a piezoelectric measurement system. The devices disclosed by the invention are applied to an application prospect for cytomechanic-electrical load measurement on cells.

Owner:XIAMEN UNIV

Overload environment thermal centrifugal test device

InactiveCN108760360AImprove reliabilityImplement federated loadingStructural/machines measurementTest chamberEngineering

The invention belongs to the simulation test technological field and relates to an overload environment thermal centrifugal test device. The device comprises a centrifuge body and a heater; the centrifuge body comprises a test chamber; a test piece fixing device for fixing a test piece is arranged in the test chamber; the heater is arranged in the test chamber; the heater comprises a quartz lamp heating component; and the quartz lamp heating component is used for simulating a thermal load borne by the test piece. According to the overload environment thermal centrifugal test device of the invention, a centrifuge is adopted to simulate an overload load, a corresponding loading curve is set according to test requirements, and therefore, the overload load can be accurately loaded, long-term operation can be realized; the quartz lamp heating component is adopted to apply the thermal load, so that the joint loading of the overload load and the thermal load can be realized; the heater is installed in the test chamber of the centrifuge body, so that the simultaneous application of heating and centrifugal overload can be realized; the applied thermal load and overload can be accurately controlled; the reliability of the heater in a centrifugal environment can be increased, and therefore, it can be ensured that long-term and high-power heating can be performed in the overload environment of the centrifuge.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

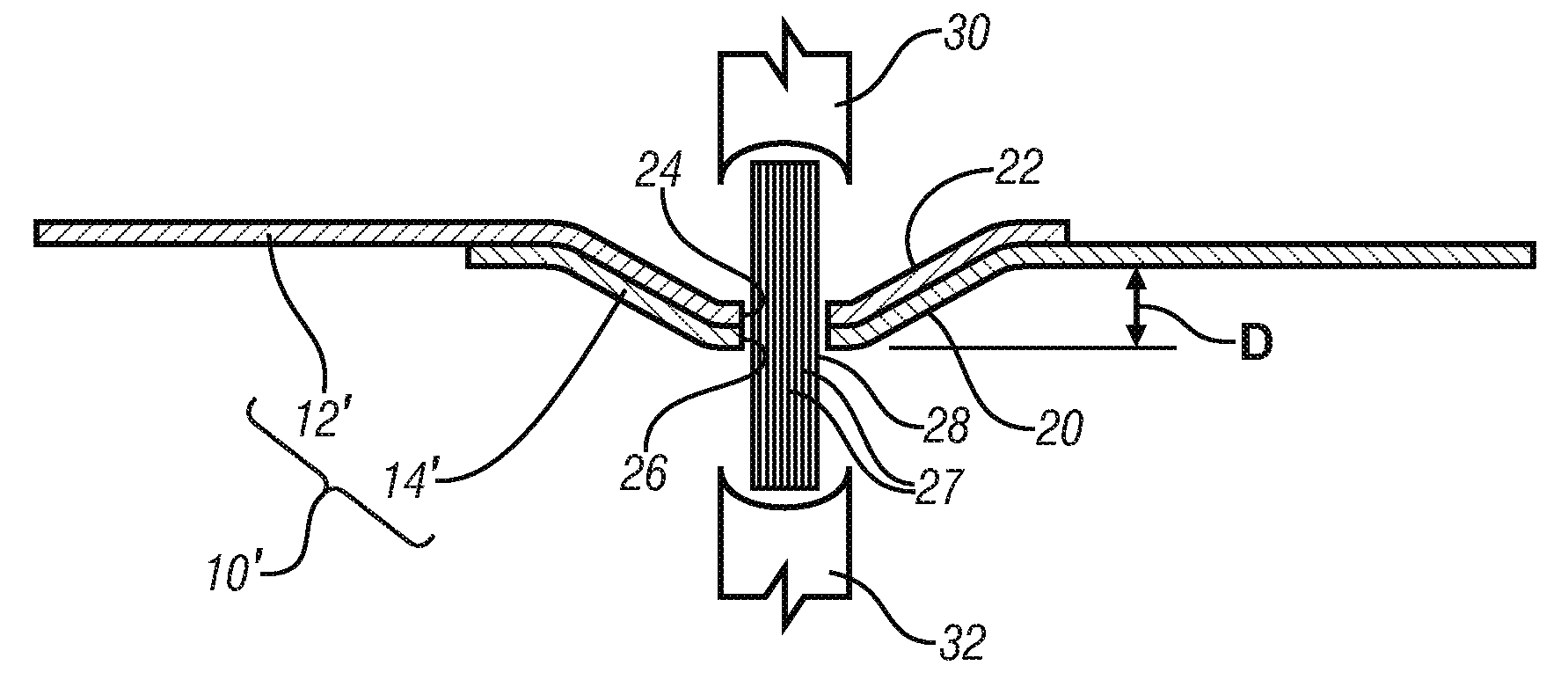

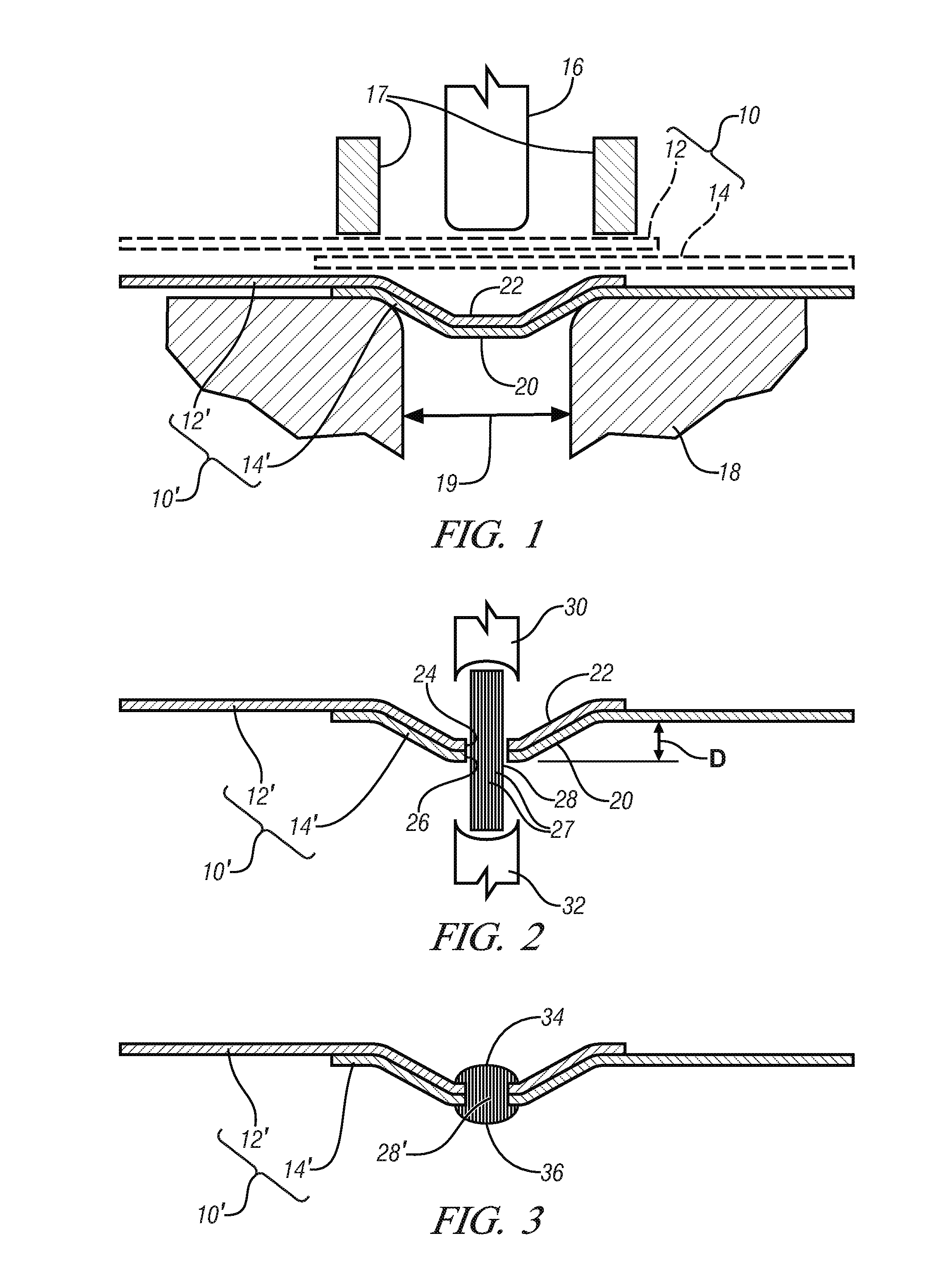

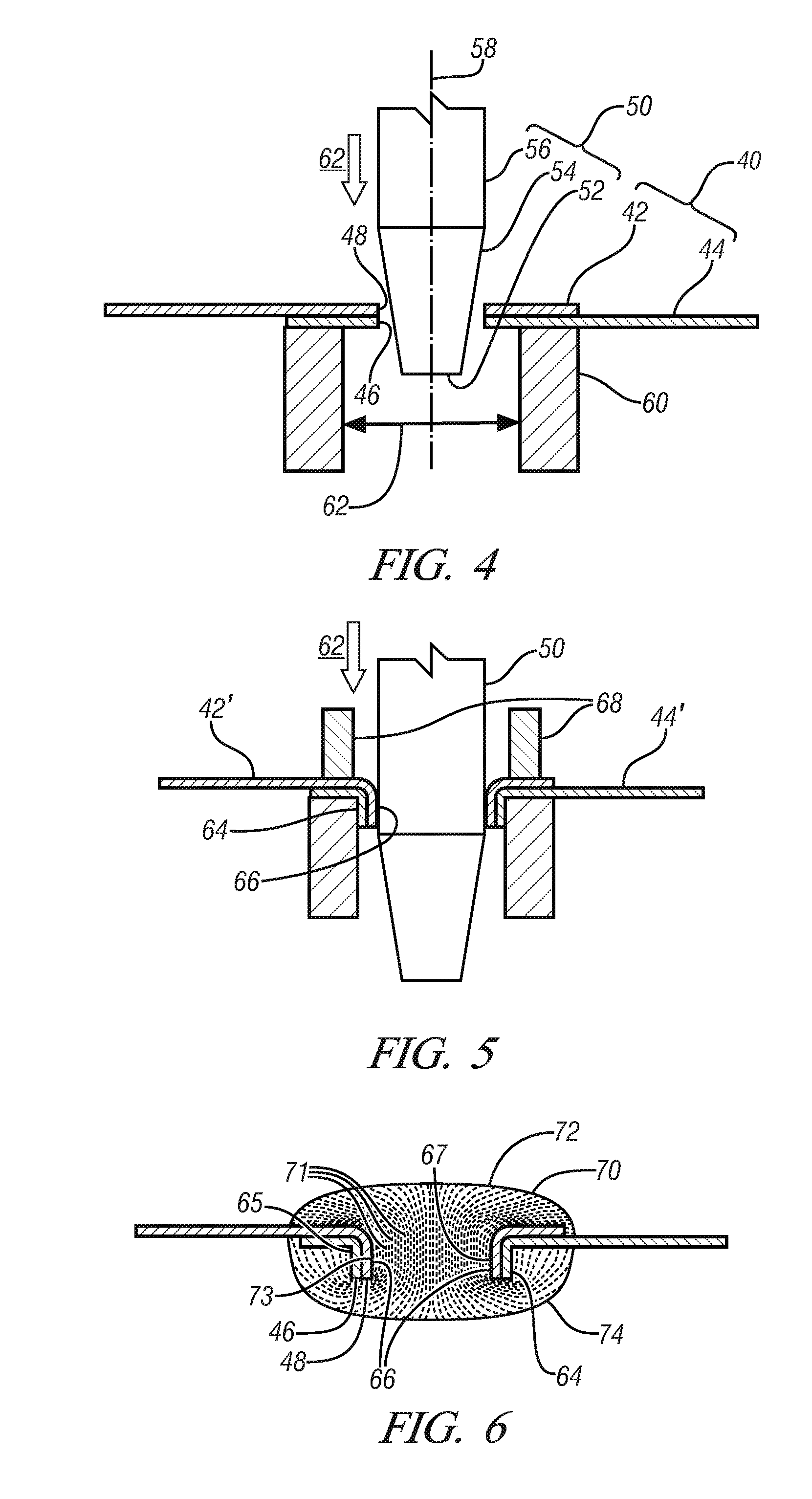

Joining magnesium with reinforced polymer composite fasteners

ActiveUS20120124816A1Superior creep resistance and dimensional stabilityImprove deformationSheet joiningMetal working apparatusPolymer compositesUltimate tensile strength

A method is disclosed for forming corrosion-resistant joints in a plurality of overlapping thin metal sheet workpieces, at least one of which comprises at least 85% by weight of magnesium sheets. The fastener is a fiber-reinforced polymer rod shaped and sized for insertion into a coaxial opening formed in each sheet and subsequently upset on each end to form a head. The workpiece sheets are deformed to form mechanically-interfering features which cooperatively complement the strength of the fastener, under at least some joint loading patterns. The method may be used for other workpiece and fastener compositions.

Owner:GM GLOBAL TECH OPERATIONS LLC

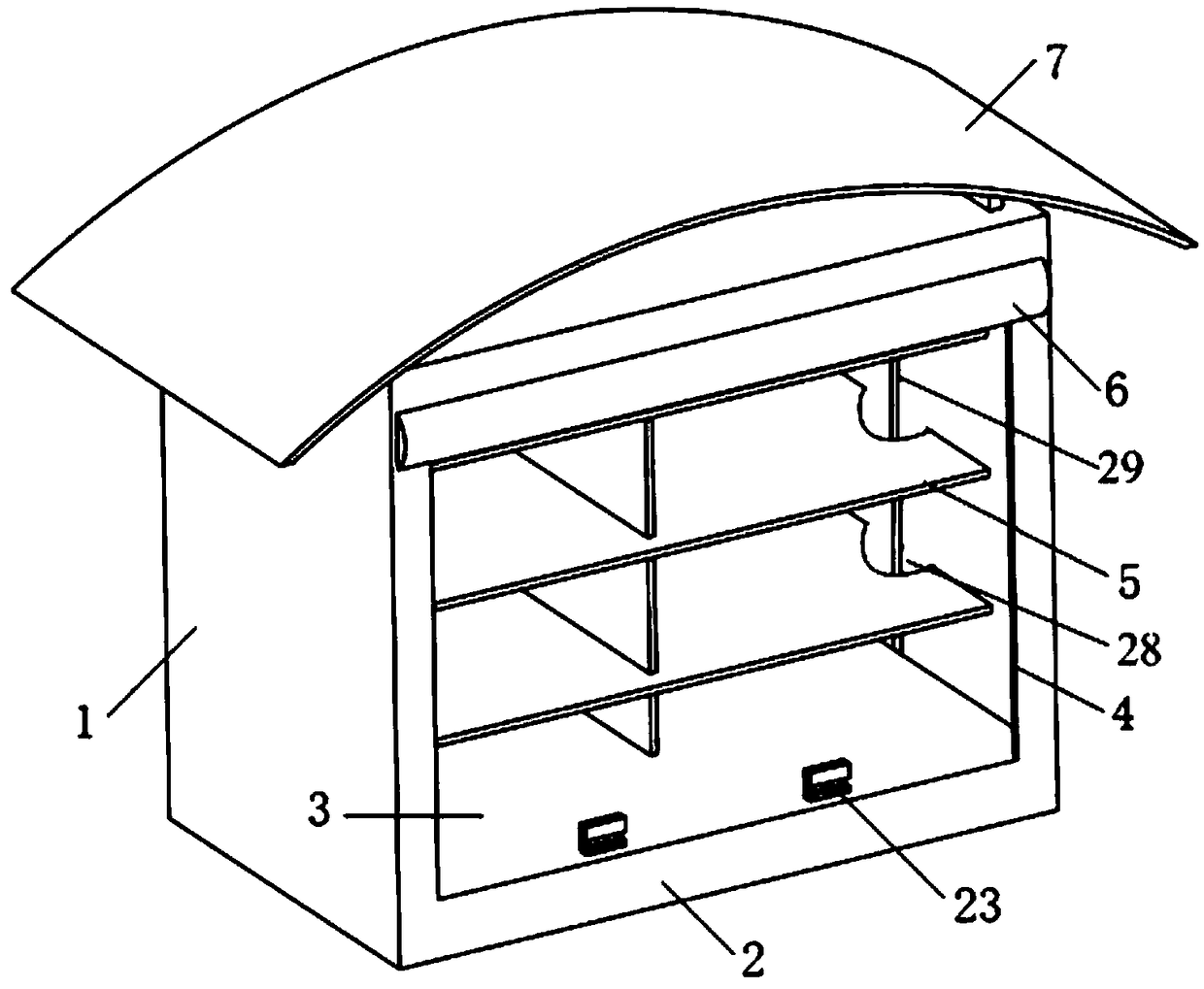

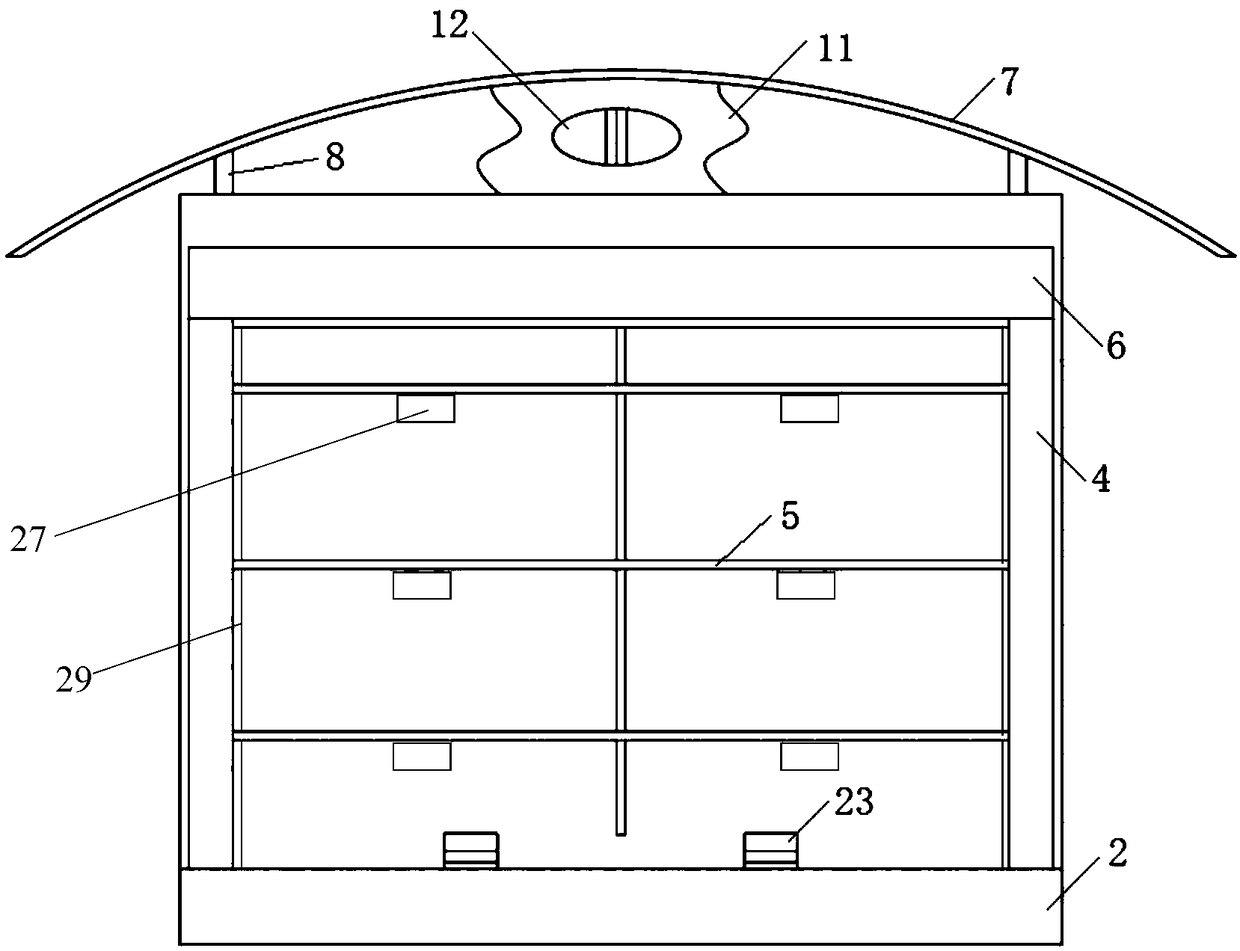

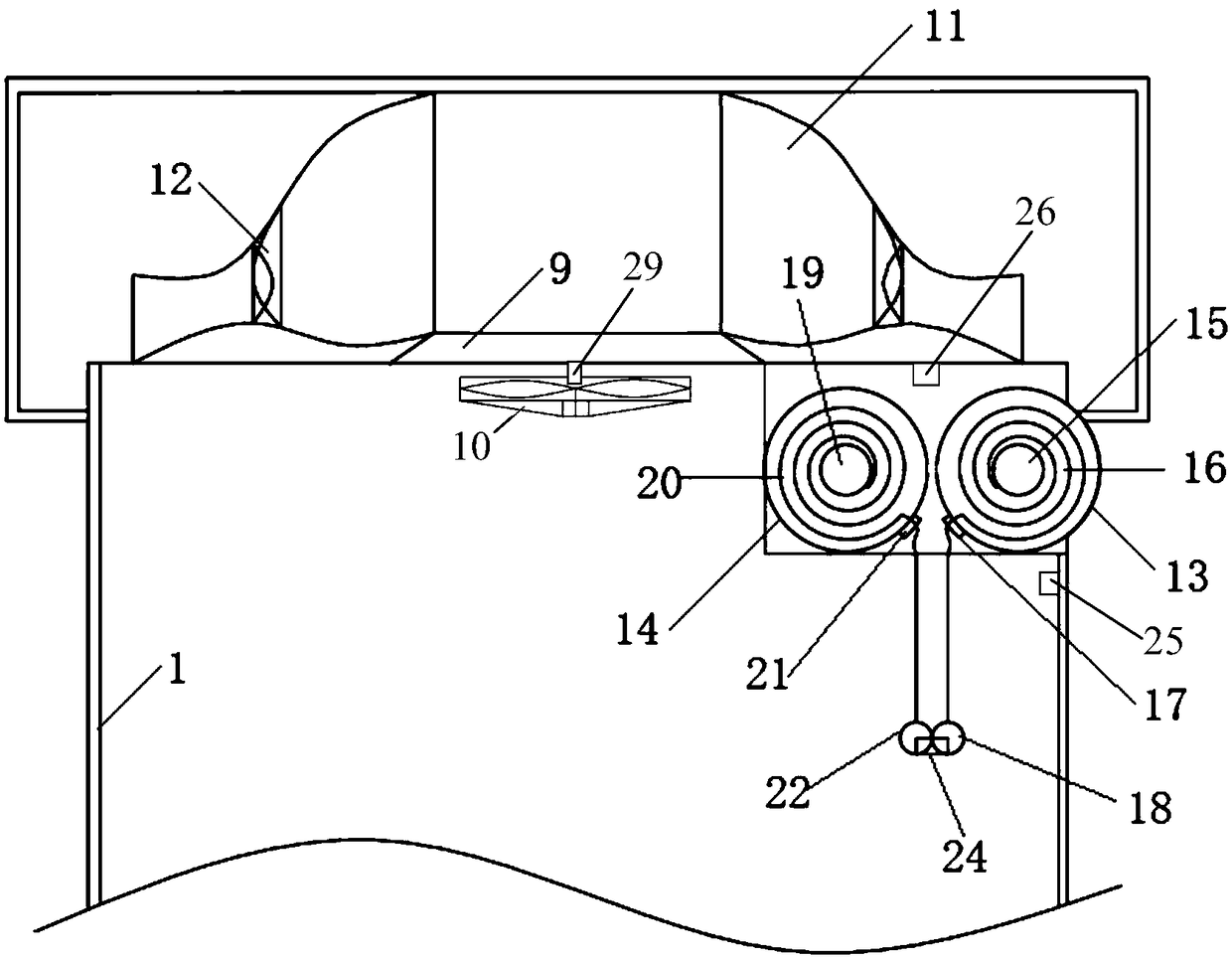

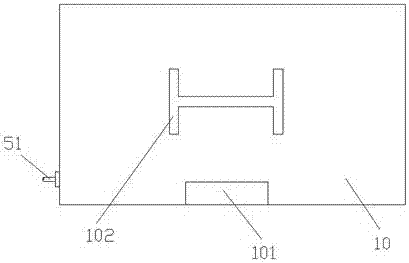

An intelligent waterproof and heat dissipation electric cabinet suitable for outdoors

ActiveCN109193425ASolve the waterproof problemAvoid troubleSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringMoisture sensor

The invention discloses an intelligent waterproof and heat dissipation power cabinet suitable for outdoors, including a power cabinet house, the bottom of the power cabinet shell is provided with a power cabinet base which is integrally spliced. The front side of the power cabinet shell is provided with a power cabinet inlet with an open structure, the two sides of the power cabinet inlet are provided with sealing plates welded on the power cabinet shell, the inner cavity of the power cabinet shell is provided with a partition plate distributed crosswise, and the top end of the power cabinet inlet is provided with a double-joint loading drum installed on the power cabinet shell. The power cabinet comprises a controller, a temperature sensor, a humidity sensor and a fan sliding along a track. The invention adopts a double-joint loading drum to integrate the anti-theft roller curtain and the waterproof cloth, and the waterproof cloth and the sealing plate are matched to block the rain water from the waterproof cloth. Through the pre-judgment and early operation of the controller, the waterproof cloth can be operated ahead of time before the arrival of the rain and snow weather, and the reliability of the waterproof device can be increased. Movable fan to improve heat dissipation efficiency by setting temperature sensors.

Owner:青岛启超微信息科技有限公司

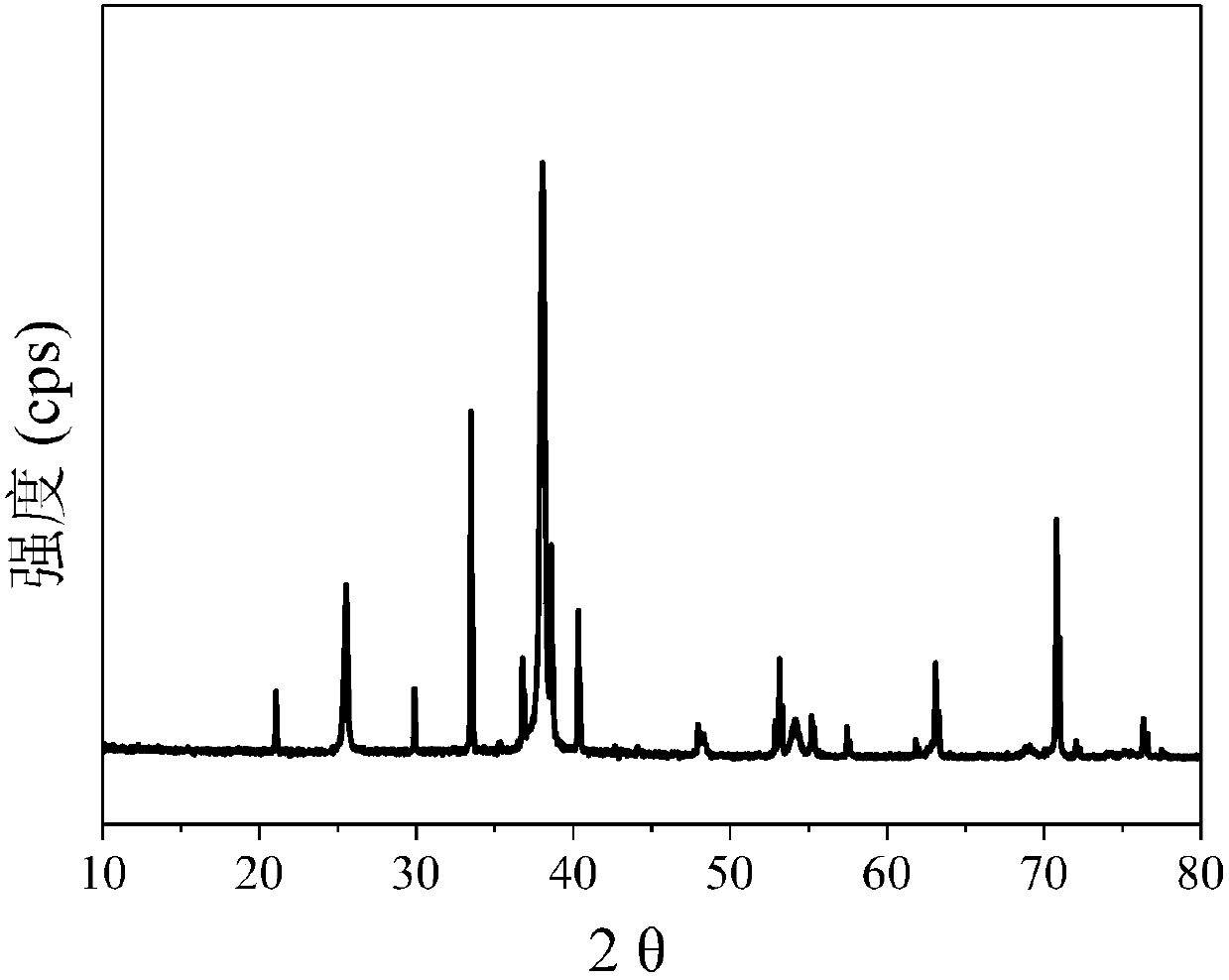

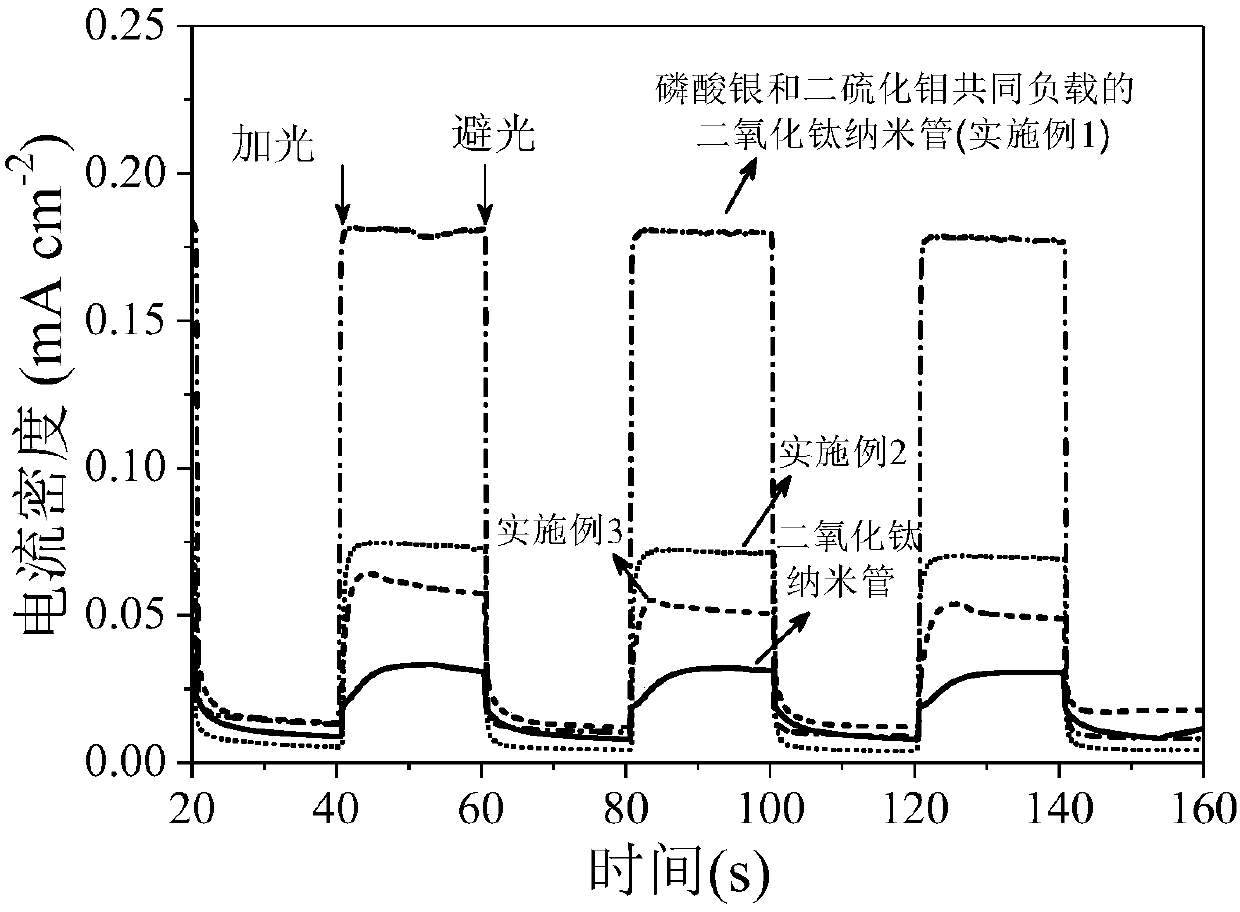

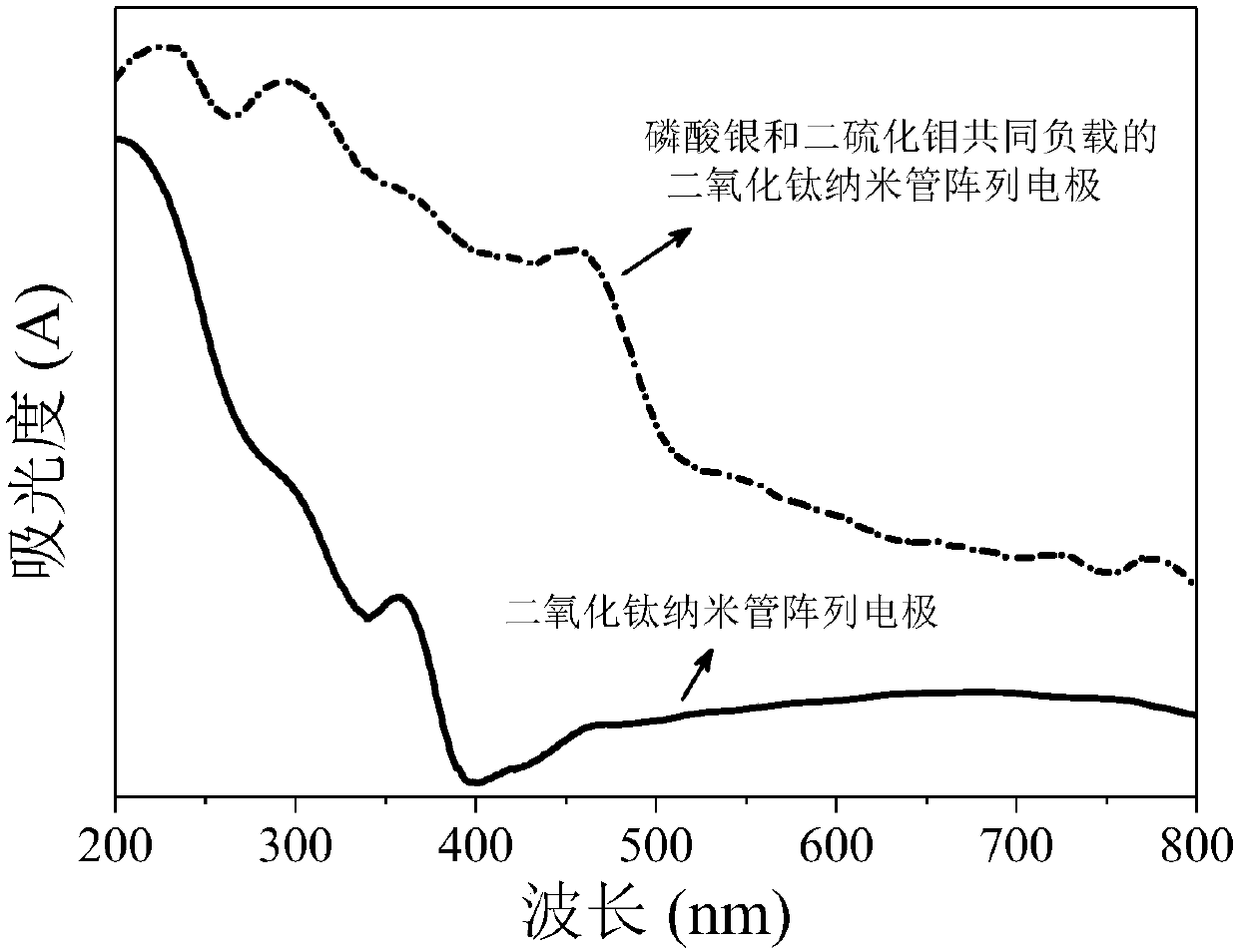

Visible light photocatalyst loading titanium dioxide nanotube electrode as well as preparation method and application thereof

ActiveCN107649154ASimple preparation processImprove visible light absorptionWater/sewage treatment by irradiationWater treatment compoundsTio2 nanotubeWastewater

The invention discloses a visible light photocatalyst silver phosphate and molybdenum disulfide joint loading titanium dioxide nanotube electrode as well as a preparation method and application thereof. The visible light photocatalyst silver phosphate and molybdenum disulfide joint loading titanium dioxide nanotube electrode prepared by the invention has obvious visible light absorption performance and simultaneously has an obvious light current response. The visible light photocatalyst silver phosphate and molybdenum disulfide joint loading titanium dioxide nanotube electrode prepared by thepreparation method disclosed by the invention is capable of degrading waste water containing antibiotics and shows good visible light photoelectrocatalysis activity. The visible light photocatalyst silver phosphate and molybdenum disulfide joint loading titanium dioxide nanotube electrode has the beneficial effects of simple technology, high degradation efficiency for waste water containing antibiotics in a visible light range, high practical value and good application prospect and can be used for large-scale industrial production, and the catalyst can be easily recovered.

Owner:JIANGSU UNIV OF SCI & TECH

Aircraft actuation system load loading device

ActiveCN106347635ASave space resourcesSave resourcesMachine part testingAircraft controlAviationActuator

The invention belongs to the technical field of aviation and particularly relates to an aircraft actuation system load loading device applicable to an aircraft actuation system loading project. According to the device, a single-actuator loading device and an aircraft airfoil loading device are improved, double effects of applying one device to single-actuator performance parameter index evaluation and aircraft airfoil actuator joint loading are realized, and a novel loading device is provided for the aircraft actuation system. The loading device provided by the invention is simple and convenient, and meets two loading needs for top loading and airfoil loading in the field of aircraft actuation system load loading through a connecting mechanism, a slider mechanism and a bracket mechanism. The resources are saved; and two processes in the aircraft loading project are realized by one mechanism, thus the equipment resources as well as the space resources of a laboratory are saved. The workflow is accelerated; and through the technical scheme, the time period of original two processes can be effectively shortened, and the process of applying an actuator to the aircraft airfoil is accelerated.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

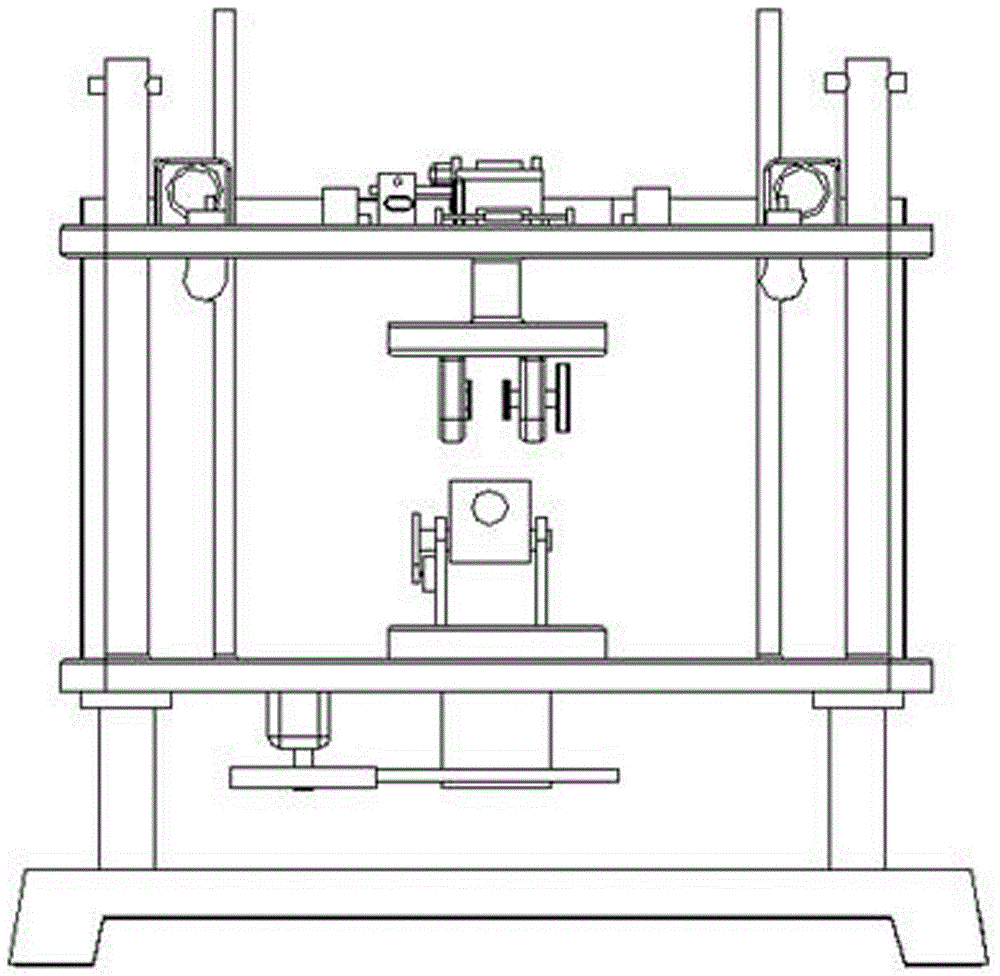

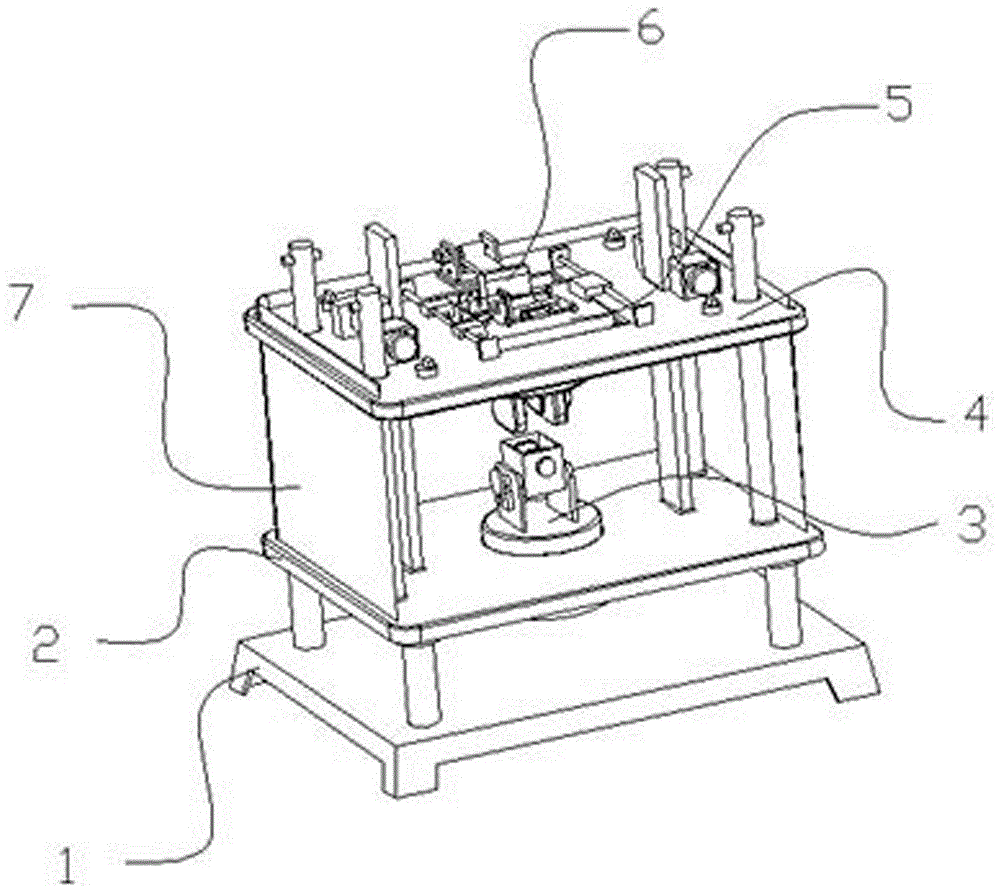

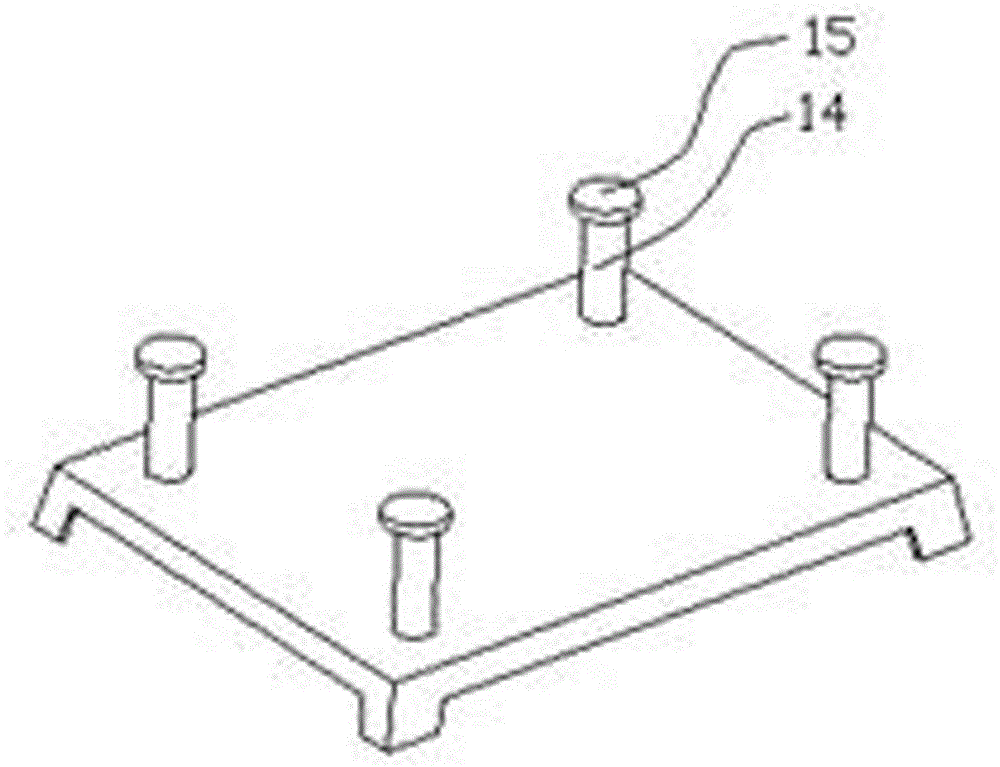

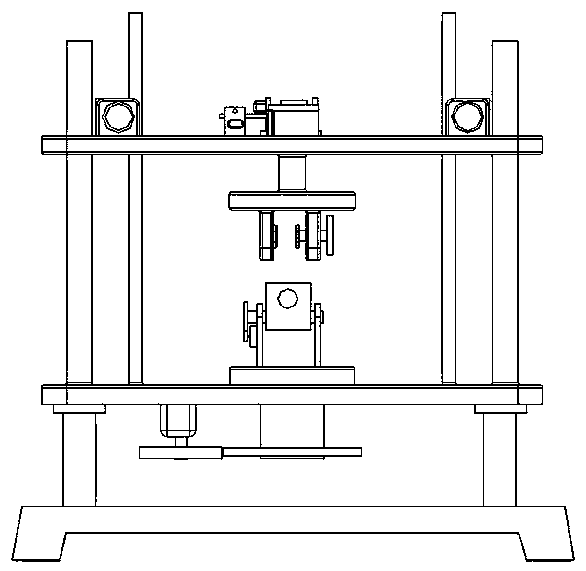

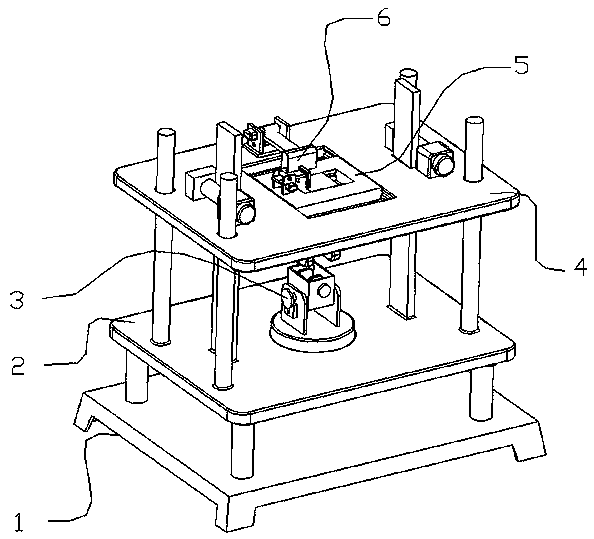

Multi-angle spinal biomechanical loading measurement device

InactiveCN106404536AEasy to operateLighting elementsMaterial strength using tensile/compressive forcesMeasurement deviceMedical equipment

The invention discloses a multi-angle spinal biomechanical loading measurement device. The device comprises a base, an experiment table, a rotating and bending loader, a vertical loader, a front-back loader and a left-right loader, wherein the rotating and bending loader and the left-right loader have a clamping function and can fix biological spines effectively, and each loader performs loading under driving of the corresponding motor. The biological spines can be loaded with force at six angles, independent loading and joint loading can be realized, basis is provided for research of spinal biomechanics, and the operation is simple. The device is suitable for being widely applied in the technical field of medical equipment.

Owner:ZHEJIANG RIBON INTELLIGENT EQUIP CO LTD

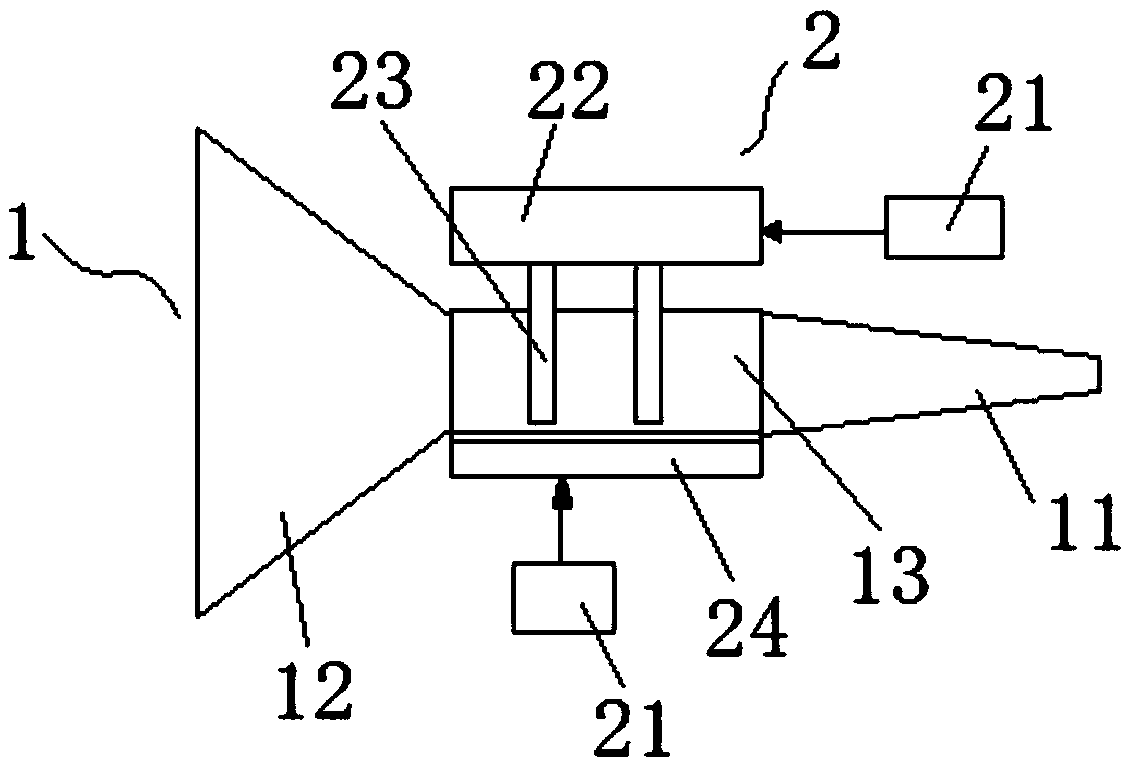

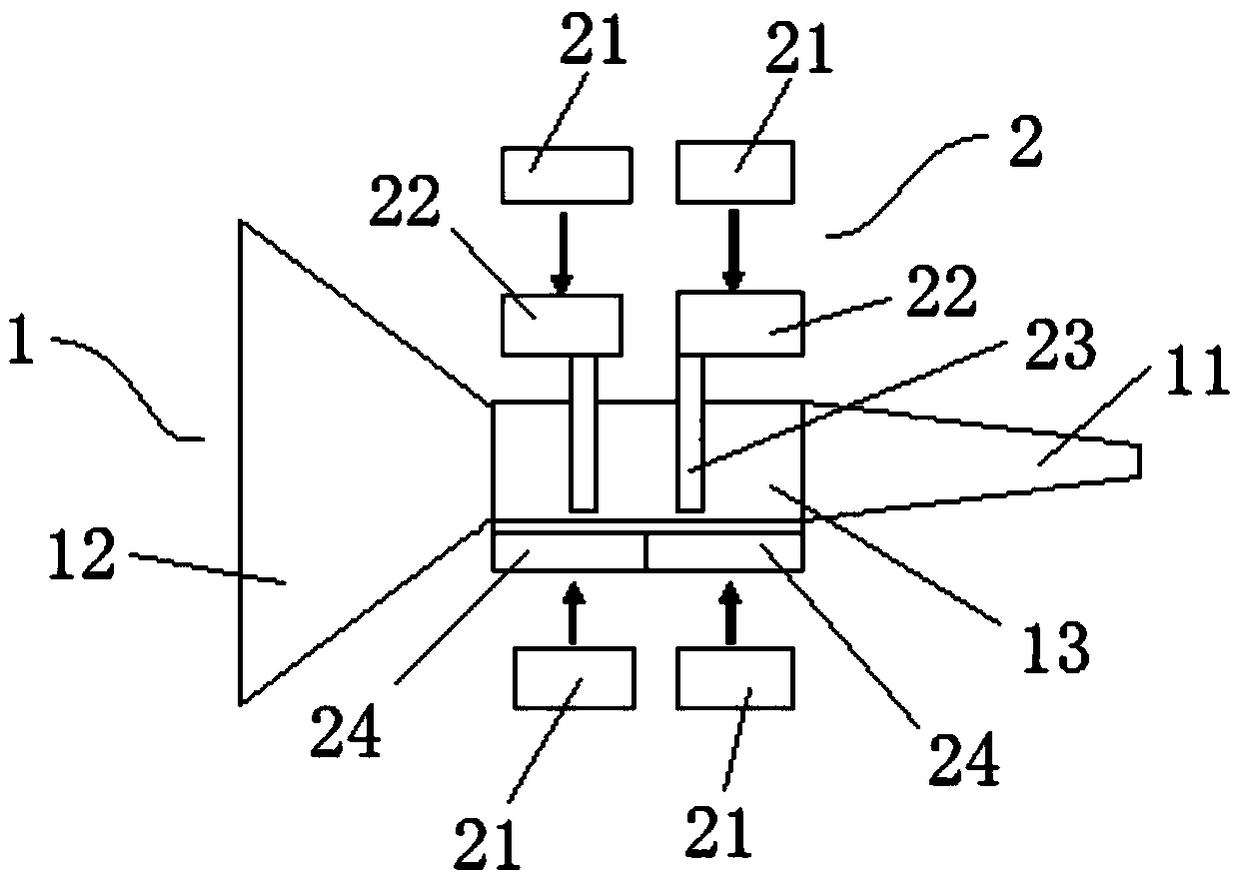

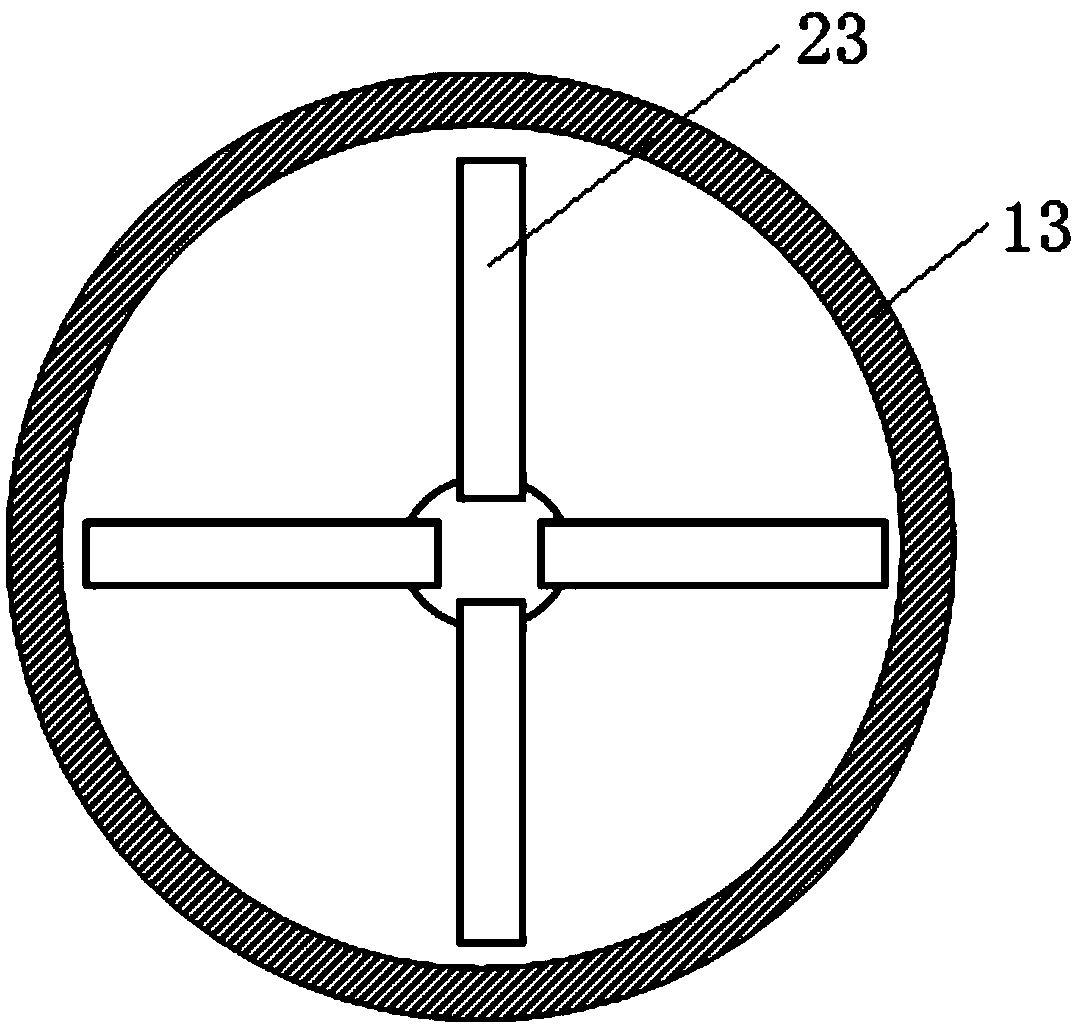

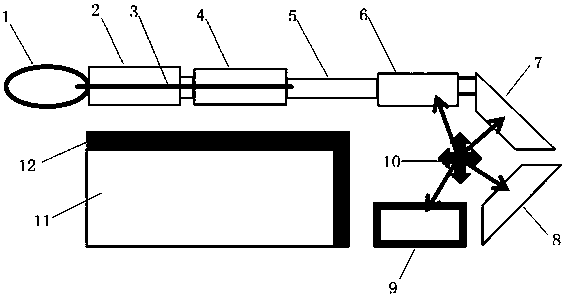

Noise and static pressure joint loading device

ActiveCN106114901AImplement partition loadingImprove test accuracyGround installationsEngineeringJoint loading

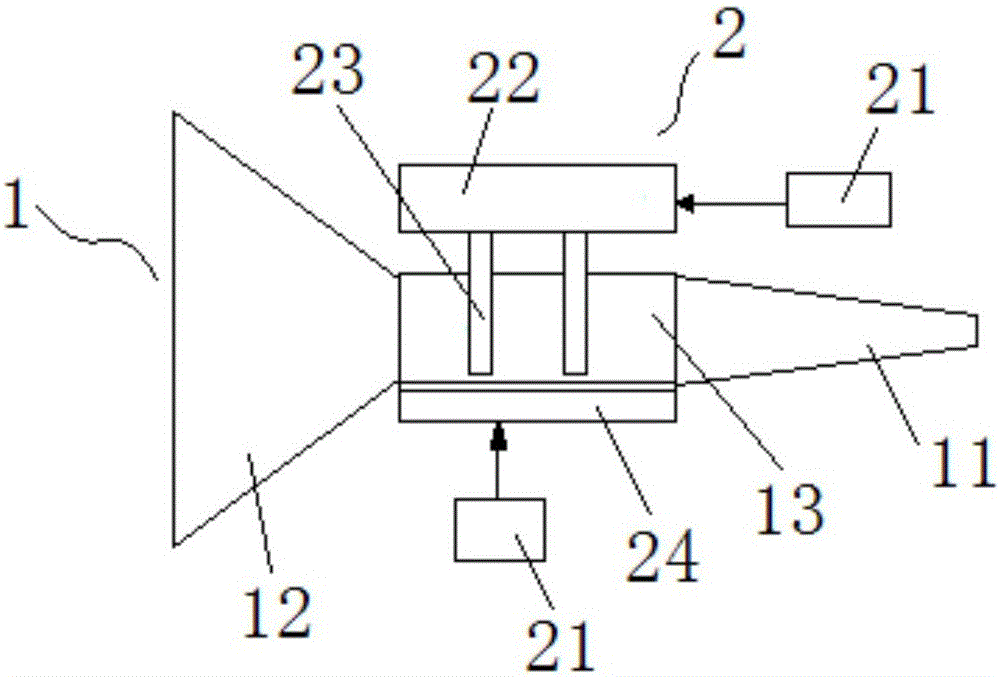

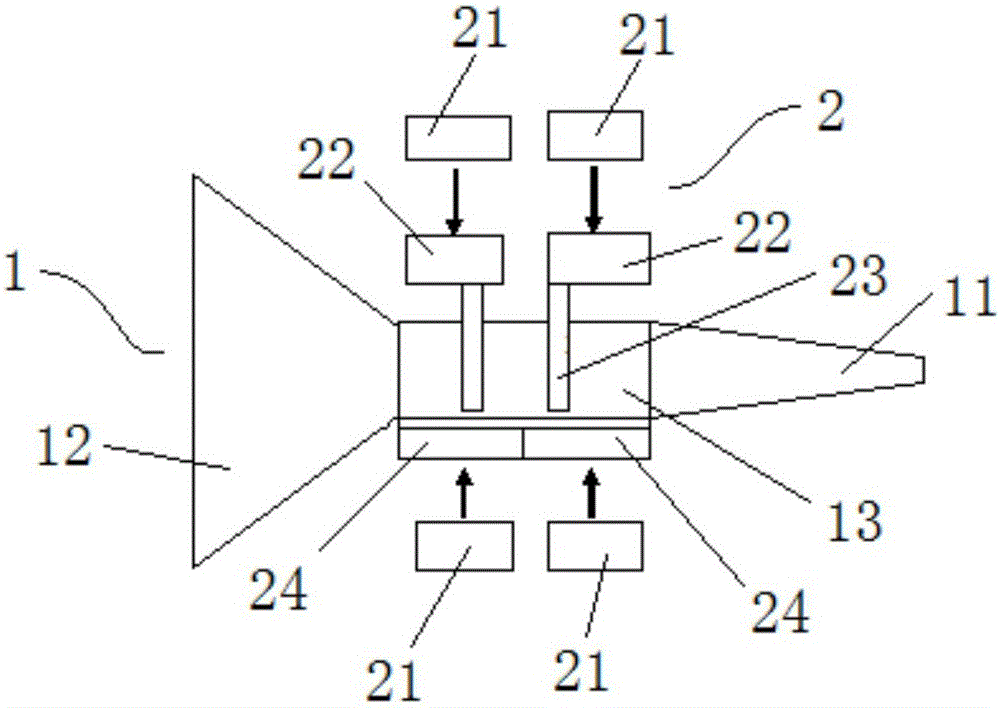

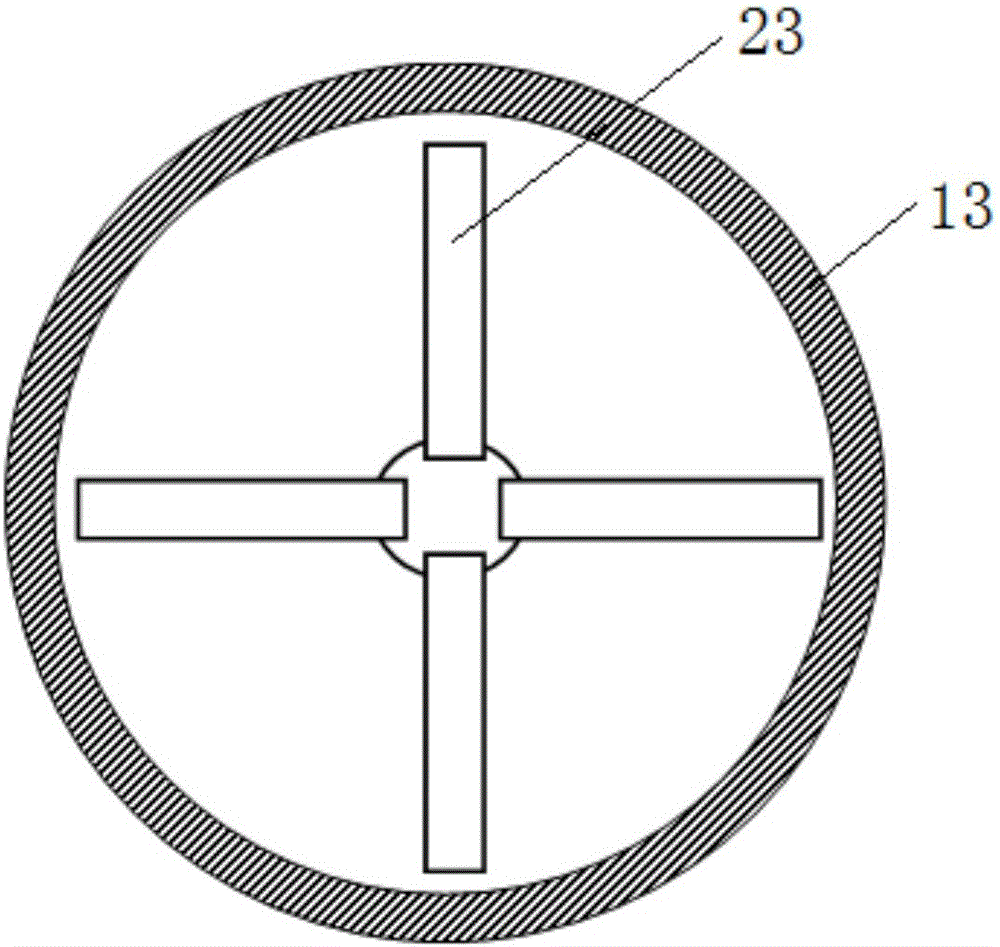

The invention discloses a combined noise and static pressure loading device. The noise and static pressure combined loading device includes a traveling wave test assembly (1) and a static pressure loading assembly (2); the traveling wave test assembly (1) includes The first diffuser section (11), the second diffuser section (12) and the test section (13); the first diffuser section (11) is an index horn, and the big end of the first diffuser section (11) is in contact with the described first diffuser section (11). One end of the test section (13) is fixedly connected; the second diffusion section (12) includes a large end opening and a small end opening in the opposite direction, and the small end opening of the second diffusion section (12) is connected to the The other end of the test section (13) is fixedly connected; the static pressure loading assembly (2) is used to apply a static pressure load to the test piece. The beneficial effect of the present invention is that: the noise load is applied to the test piece by the traveling wave test assembly, and the static pressure load is applied to the test piece by the static pressure loading assembly, so that the joint application of noise and static pressure load can be realized.

Owner:CHINA AIRPLANT STRENGTH RES INST

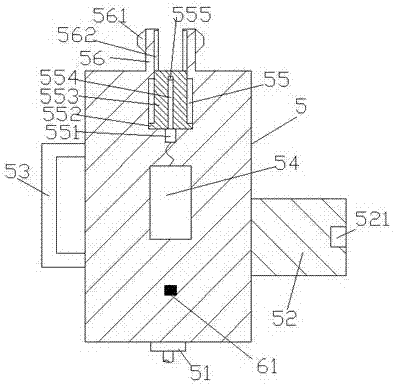

Novel thick book binding machine

The invention discloses a novel thick book binding machine. The novel thick book binding machine comprises a main body, a first thick book binding device, a second thick book binding device and a thick book punching device, wherein the first thick book binding device is arranged on the main body; the second thick book binding device is arranged in the main body; the thick book punching device is arranged on the main body; the first thick book binding device comprises a first fixed block and a second fixed block; and the first fixed block and the second fixed block are fixedly arranged at the upper end of the main body. The country is growing faster and faster now, plenty of materials need to be bound in daily life and work, the materials are thick, and simple binding machines cannot meet the demands of people; the novel thick book binding machine is capable of realizing rapid, efficient and stable binding of thick books; an automatic snap joint loading device is arranged in the novel thick book binding machine and snap joints do not need to be manually changed in binding of the thick books, so that various demands of users are satisfied; and the design of the book binding machine convenient for binding is necessary.

Owner:何龙飞

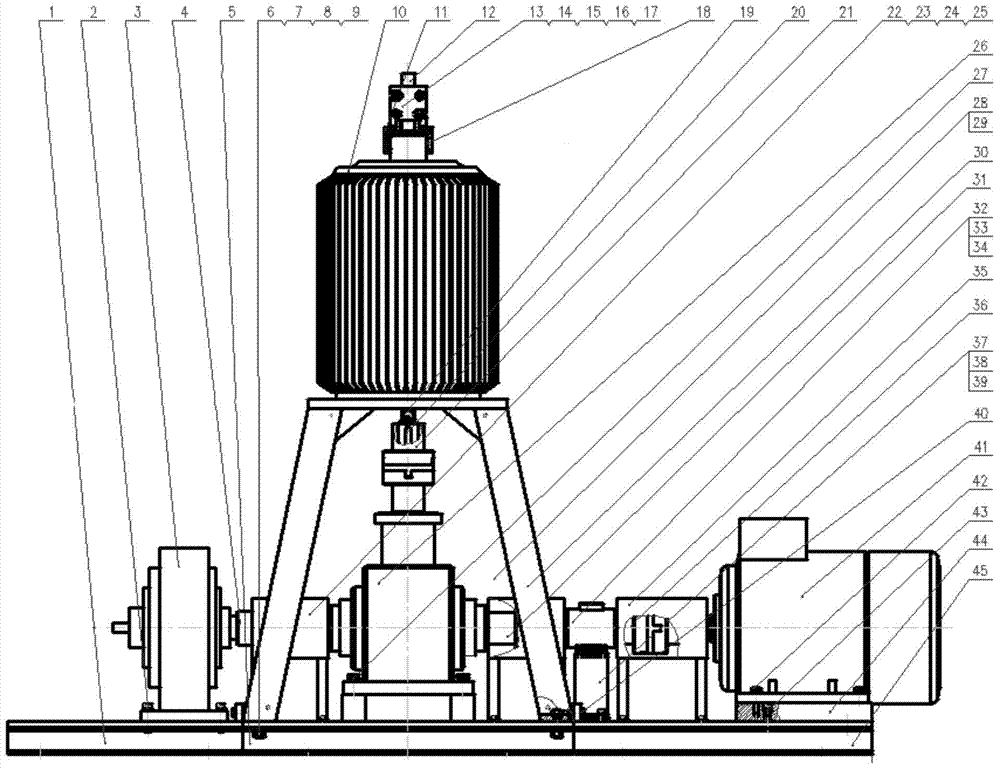

Electric-propulsion joint loading test system

InactiveCN103792064AImprove accuracyIncrease flexibilityHydrodynamic testingElectric machineEngineering

The invention provides an electric-propulsion joint loading test system. A magnetic powder brake is installed on a magnetic powder brake base, a reversing device is installed on a base, a six-direction motor is installed on a motor cushion plate installed on a motor base, a permanent-magnetism motor is installed on a permanent-magnetism motor support fixed to the base, the reversing device is located on the permanent-magnetism motor support and below the permanent-magnetism motor, the magnet powder brake base, the base and the motor base are sequentially connected, a torque sensor is installed on the motor base through a torque sensor base connected with the permanent-magnetism motor support, the magnet powder brake is connected with a left opening of the reversing device, a right opening of the reversing device is connected with the torque sensor connected with the six-direction motor, and an upper opening of the reversing device is connected with the permanent-magnetism motor. The electric-propulsion joint loading test system overcomes defects of a single motor or magnetic powder brake loading system and further improves motor loading accuracy and flexibility.

Owner:HARBIN ENG UNIV

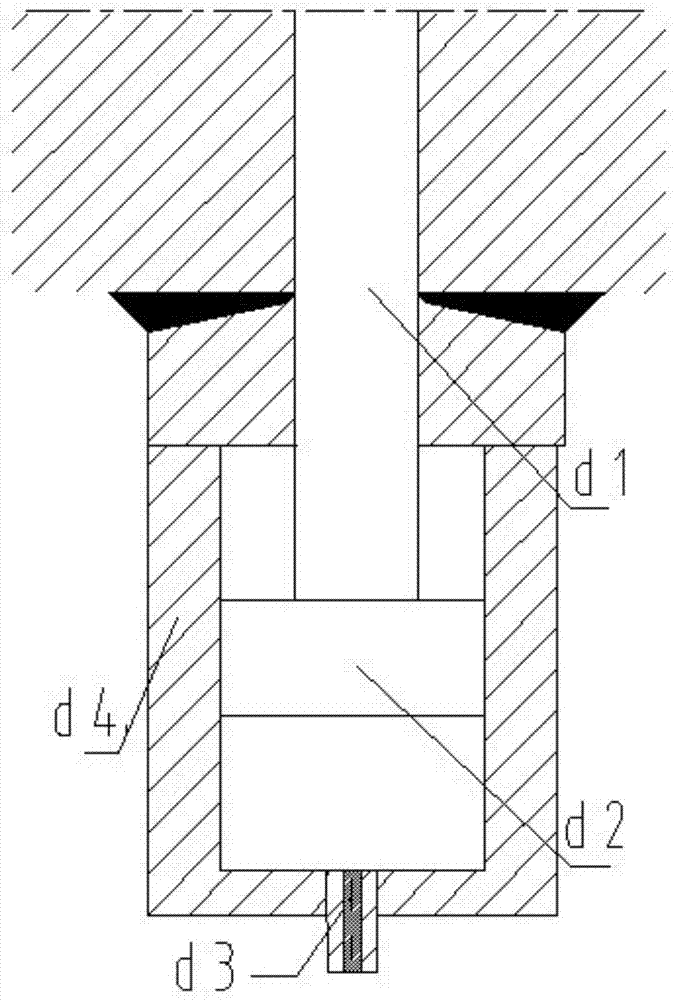

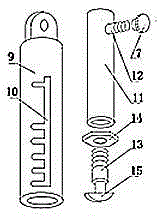

Hydraulic type torsion connection simulator

The invention discloses a hydraulic type torsion connection simulator and relates to a torsion calibration device. A piston rod consists of an upper piston rod, a piston and a lower piston rod, wherein the lower piston rod consists of a large-diameter round rod, a transitional cone body and a small-diameter round rod, a stepped cylindrical cavity is formed at the top end of a hydraulic cylinder ofthe simulator, and comprises a large-diameter cylinder inner cavity and a small-diameter cylinder inner cavity, the piston divides the large-diameter cylinder inner cavity into an upper cavity and alower cavity, a channel is arranged inside the wall of the hydraulic cylinder of the simulator, the lower piston rod is provided with a piston reset spring supported between the piston and the end surface of the ledge of the large-diameter cylinder inner cavity in a sleeved manner, the hydraulic cylinder of the simulator is filled with hydraulic oil, an upper sealing cover of the cylinder is sealed at the top end of the hydraulic cylinder of the simulator, the upper end of the upper piston rod extends out of a sealing hole in the upper sealing cover of the cylinder, an upper cover is fixed onthe upper sealing cover of the cylinder, and a threaded loading joint is in threaded connection with a threaded hole in the upper cover. The simulator has the advantages that the adaptability is strong, the cost can be lowered, and the labor capacity and the labor intensity can be reduced.

Owner:哈尔滨市计量检定测试院

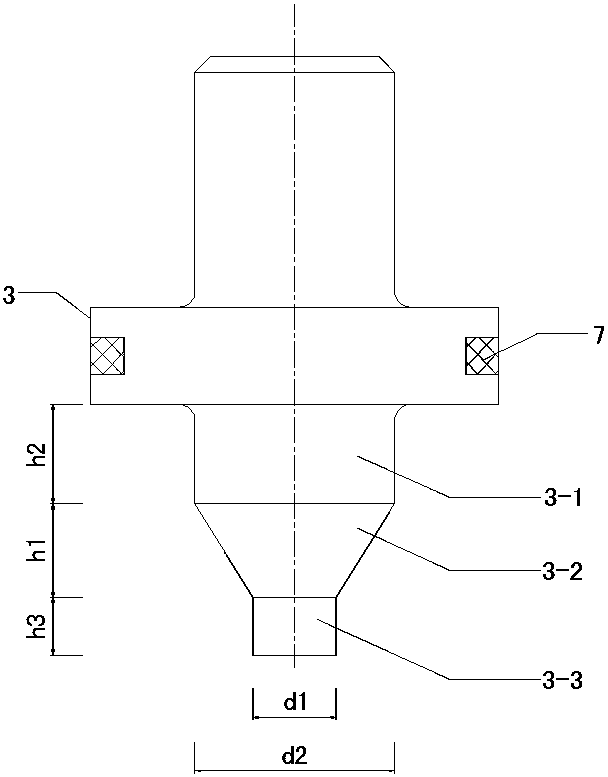

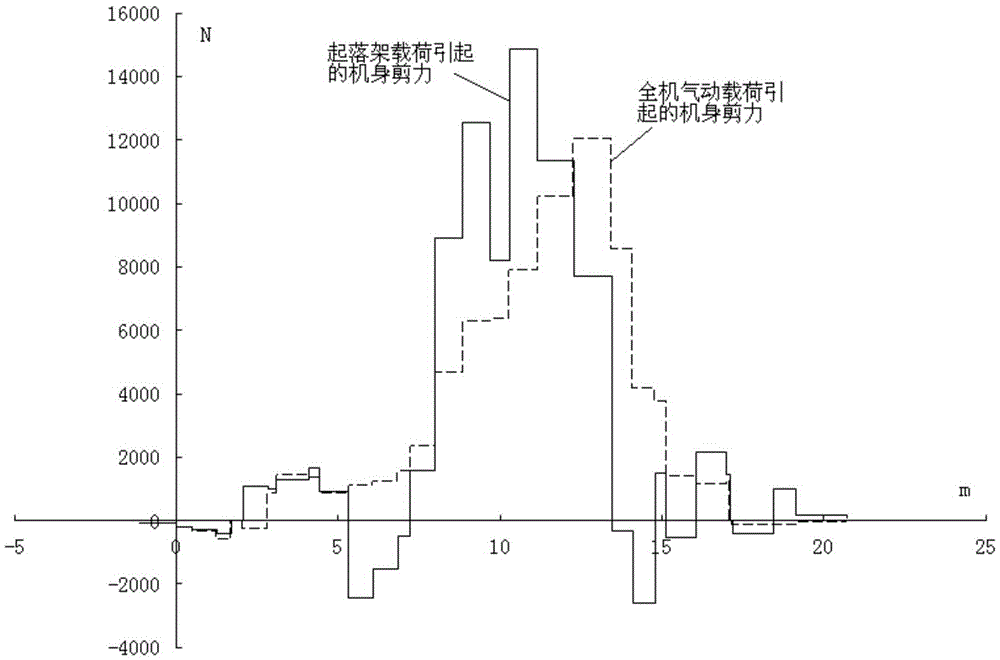

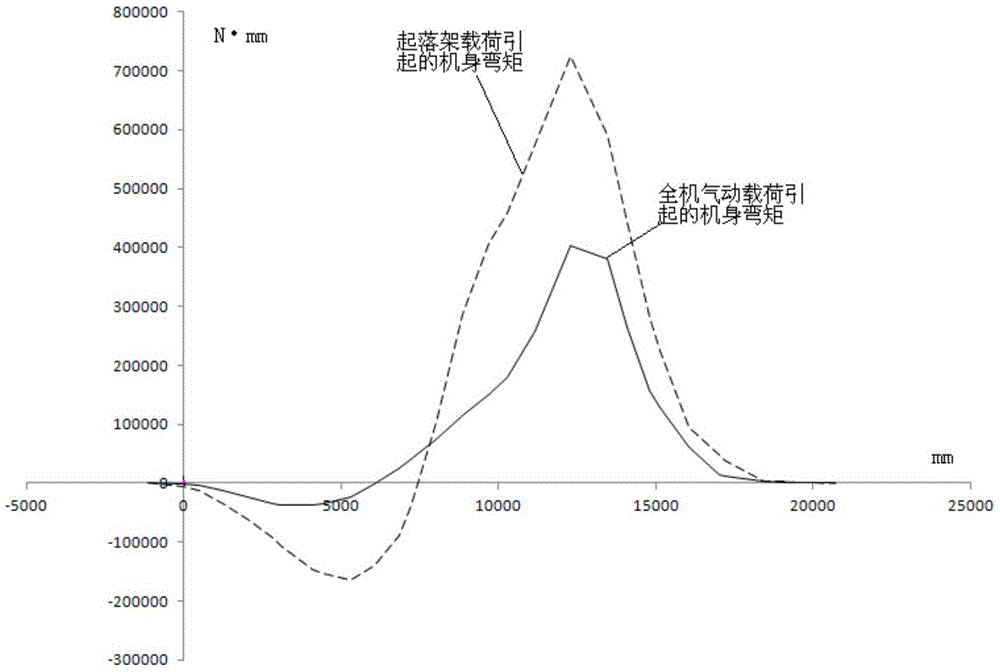

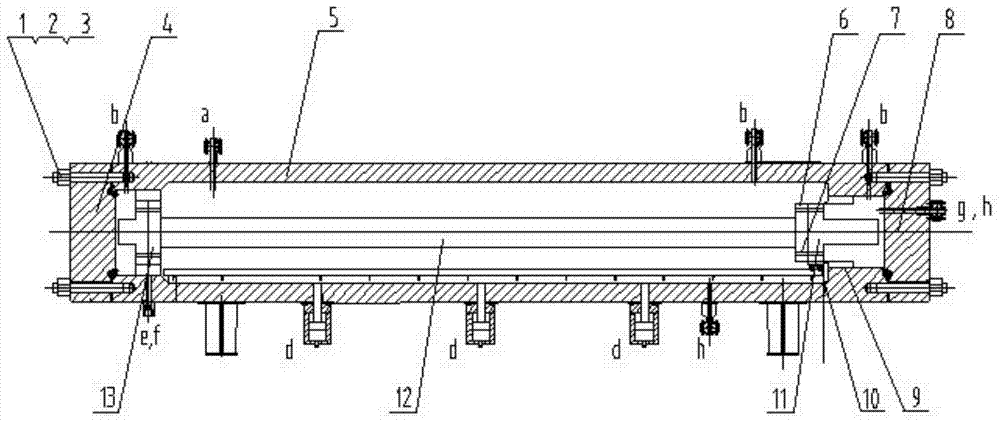

A verification test method for joint loading of aircraft body and landing gear

ActiveCN103983463BShorten the test scheduleImprove test efficiencyStructural/machines measurementJet aeroplaneStatic strength

The invention belongs to the field of airplane design and relates to a method for a verification test of combined loading of an airframe and an undercarriage. The method is characterized in that firstly, assessment of a load is conducted; secondly, a loading scheme is designed; thirdly, loading is tested; the load of the undercarriage serves as an examination working condition of a full-aircraft static test, combined loading of the airframe and the undercarriage is achieved in the full-aircraft static test, and an airframe structure static strength design envelope under the special working condition of the undercarriage can be fully verified.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

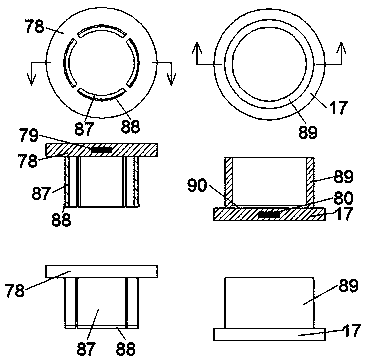

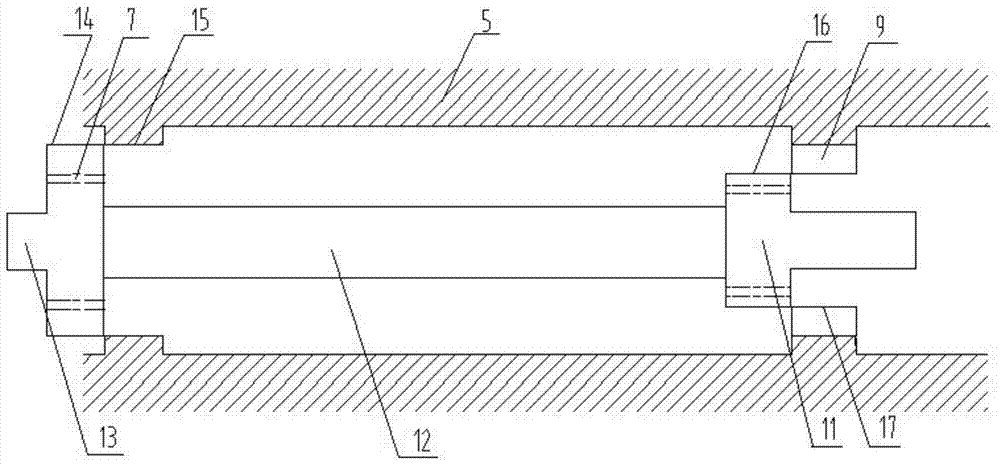

Combined loading buckling test device for submarine pipeline complex load

ActiveCN105424484BEffective test accumulationComprehensive force analysisMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesEngineeringSubmarine pipeline

The invention relates to a test device for complex loading and united loading buckling of a submarine pipeline. The test device is used for testing a test pipeline (12) and comprises a main cabin (5), a lateral hydraulic rod device d, a front-end flange (13), two sets of rear-end flanges (11) and circular cylinders (9) with threads, wherein the lateral hydraulic rod device d is used for applying bending moment to the test pipeline (12); the rear-end flanges (11) and the circular cylinders (9) are matched with each other on the threads; the thread matched with the front-end flange (13) is arranged on an inward bulge part at the front end of the main cabin (5); the first set of rear-end flange (11) and circular cylinder (9) with threads has a thread pitch of the thread identical to the thread pitch of the front-end flange and is called as category I; the second set of rear-end flange (11) and circular cylinder (9) with threads has the thread pitch of the thread different from the thread pitch of the front-end flange and is called as category II. The test device can be used for simulating the practical operation environment of the full-size submarine pipeline in the paving and service periods.

Owner:TIANJIN UNIV

A Noise and Static Pressure Combined Loading Device

ActiveCN106114901BImplement partition loadingImprove test accuracyAircraft components testingEngineeringJoint loading

The invention discloses a noise and static pressure joint loading device. The noise and static pressure joint loading device comprises a traveling wave experiment assembly (1) and a static pressure loading assembly (2), wherein the traveling wave experiment assembly (1) comprises a first diffusion section (11), a second diffusion section (12) and an experiment section (13); the first diffusion section (11) is an exponential horn, and the big end of the first diffusion section (11) is fixedly connected with one end of the experiment section (13); the second diffusion (12) comprises a big end opening and a small end opening in opposite directions, and the small end opening of the second diffusion section (12) is fixedly connected with the other end of the experiment section (13); and the static pressure loading assembly (2) is used for exerting a static pressure load to an experimental sample. The noise and static pressure joint loading device disclosed by the invention has the beneficial effects that a noise load is exerted to the experimental sample through the traveling wave experiment assembly, the static pressure load is exerted to the experimental sample through the static pressure loading assembly, and the joint exerting of the noise load and the static pressure load can be realized.

Owner:CHINA AIRPLANT STRENGTH RES INST

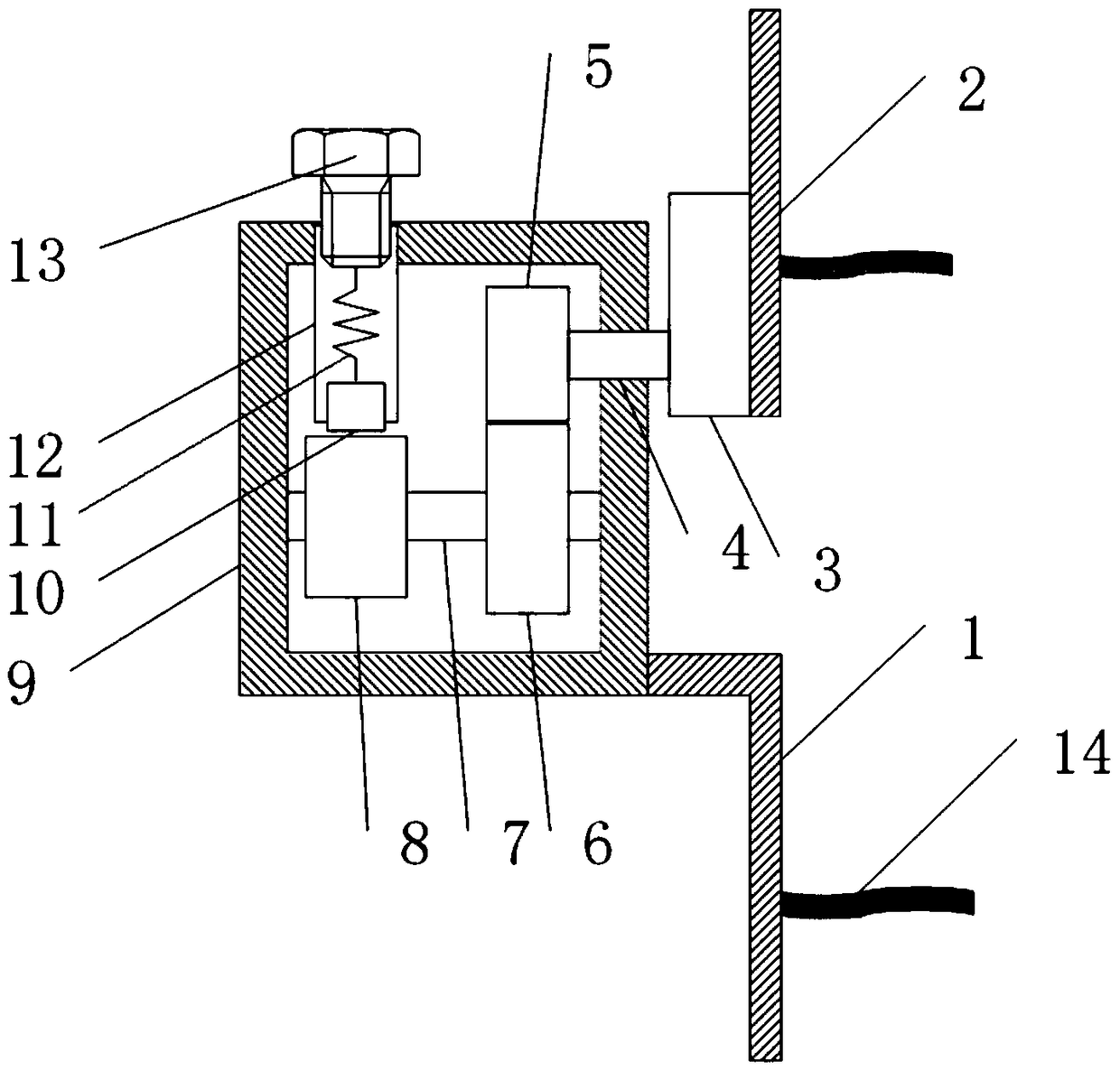

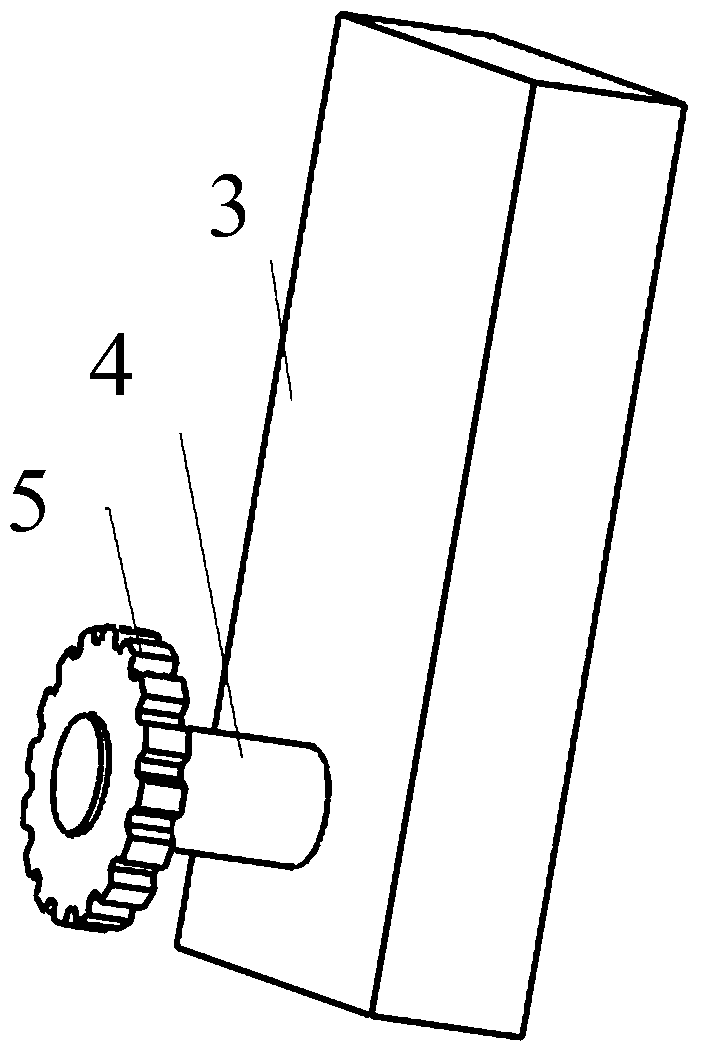

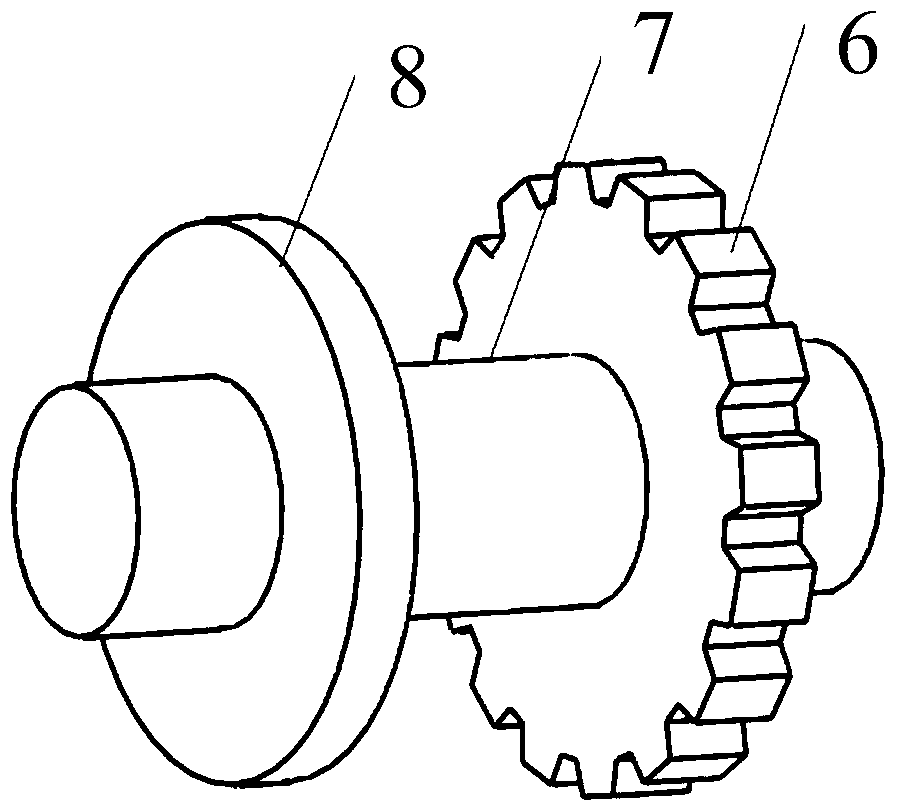

A joint load capacity measuring device

ActiveCN105738191BChange the amount of frictionRealize measurementStrength propertiesThighMeasurement device

The invention discloses a measuring device for the joint loading capacity.The measuring device is composed of a crus fixing plate, a thigh fixing plate, a torque measuring instrument, a first transmission shaft, a driving gear, a transmission gear, a second transmission shaft, a friction wheel, a shell, a friction block, a spring, a spring sleeve, a pressure adjusting knob and bandages.In the measuring device for the joint loading capacity, loads, generated by a knee-joint energy collecting device during working, to knee joints are simulated through friction force, and different loads, generated by the knee-joint energy collecting devices with different generating capacities, to the knee joints are simulated by adjusting the friction force.When the joint loading capacity is tested, as the friction force in the measuring device for the joint loading capacity is changed, and physiological experience indexes such as the discomfort strength and the fatigue strength of a wearer are counted, the capacity of bearing external loads by the knee joints of the wearer is determined.

Owner:NANJING UNIV OF POSTS & TELECOMM

Human leg joint load-bearing relief device

InactiveCN103932825BLighten the loadRelieve painNon-surgical orthopedic devicesArtificial legsHuman bodyThigh

The invention relates to a buffering device for bearing force of the human body leg joints and belongs to the technical field of joint health care. The buffering device for the bearing force of the human body leg joints comprises supporting mechanisms, suspender pants (19) and shoes. Each supporting mechanism comprises an upper knee joint supporting combination, a lower knee joint supporting combination and an ankle supporting combination. The suspender pants (19) comprise inner layers and outer layers. One set of the upper knee joint supporting combination and the lower knee joint supporting combination is arranged between the inner layer and the outer layer of a left pant leg, and one set of the upper knee joint supporting combination and the lower knee joint supporting combination is arranged between the inner layer and the outer layer of a right pant leg. The ankle supporting combinations are arranged on heel parts inside the shoes. A patient wears the suspender pants (19) and the shoes where the ankle supporting combinations are installed, so that the bottoms of the heels of the human body make slight contact with heel bottom plates (18) when the heels of the shoes touch the ground because a certain distance is formed between the bottoms of the heels of the human body and the heel bottom plates (18). Under the action of the supporting mechanisms, the acting points of the weight of the human body are formed on the roots of the thighs and the hips, so that the bearing force of the leg joints is greatly reduced, and pains of the legs are relieved.

Owner:SICHUAN LANYI TECH

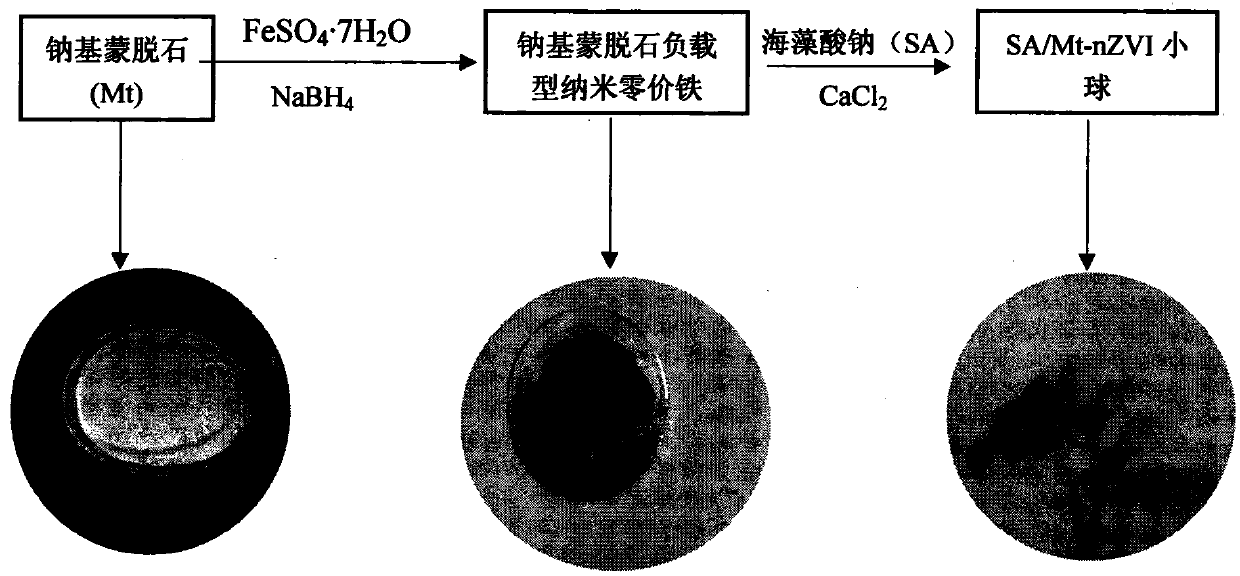

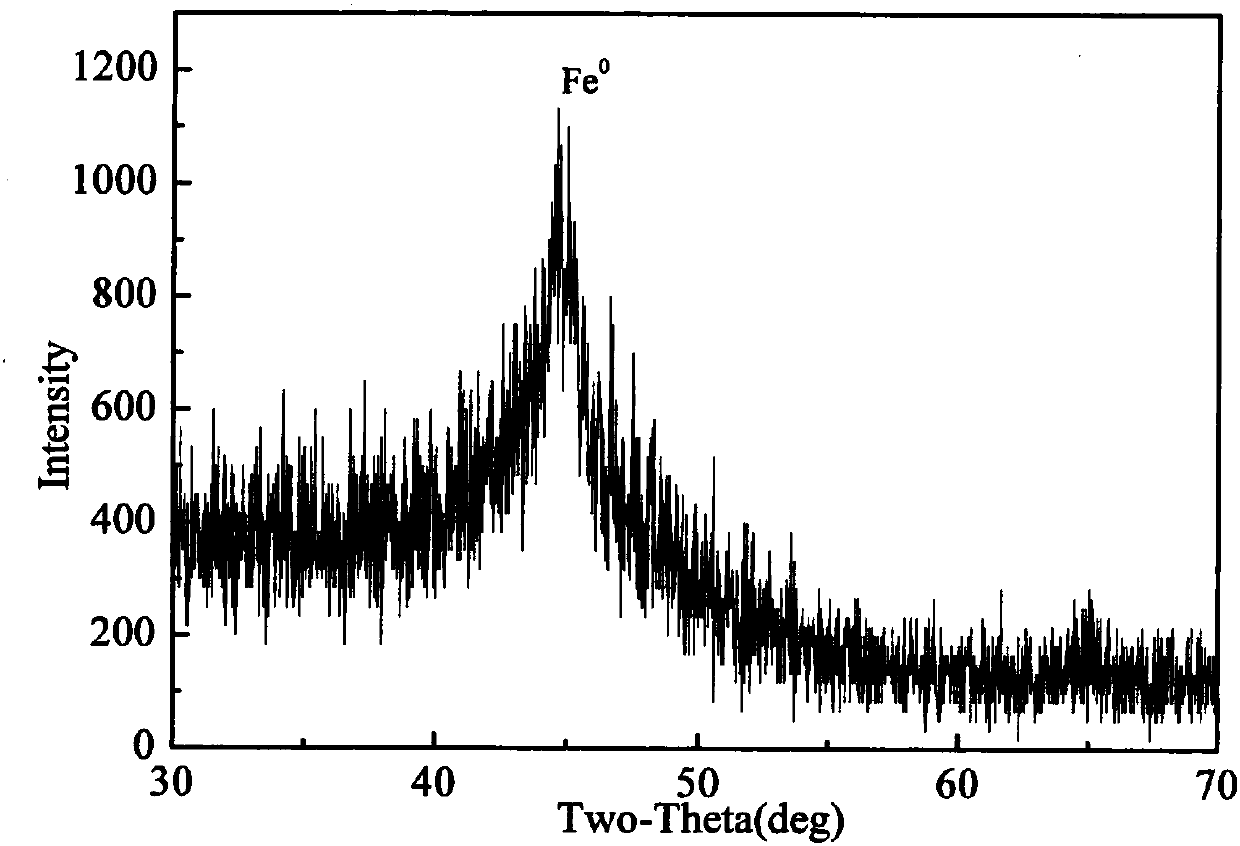

Preparation method of sodium alginate/inorganic mineral joint-loaded nanometer zero-valent iron

ActiveCN105921763BAvoid reunionLarge apertureMaterial nanotechnologyTransportation and packagingNitrogen gasVacuum drying

The invention provides a method for preparing sodium alginate / inorganic mineral joint-supported nano-zero-valent iron, which is characterized in that it comprises: preparing inorganic mineral-supported nano-zero-valent iron; preparing seaweed with a mass concentration of 1% to 3% Sodium acid solution; under the protection of nitrogen, the inorganic mineral-loaded nano-zero-valent iron and sodium alginate solution are mixed to obtain a sodium alginate / inorganic mineral-loaded nano-zero-valent iron blend; the sodium alginate / inorganic mineral-loaded The nano-type zero-valent iron blend is added dropwise into the CaCl2 solution with a syringe for cross-linking reaction to obtain spherical sodium alginate / inorganic mineral joint-loaded nano-zero-valent iron; cleaning, reduction, and vacuum drying to obtain sodium alginate / inorganic Mineral joint-loaded nano-scale zero-valent iron finished product. The invention has better removal effect on heavy metals in water environment. Taking the removal of Cu(II) as an example, after 24 hours of reaction, the removal rate can reach more than 90%.

Owner:上海泽耀环保科技有限公司

Motor end cover intelligent production line

PendingCN108637693AQuality improvementIncrease productivityOther manufacturing equipments/toolsLarge fixed membersProduction lineNumerical control

The invention discloses a motor end cover intelligent production line. The motor end cover intelligent production line comprises a loading table; the loading table is an initial end of a production line; a rough machining numerical control lathe is arranged at a subsequent end of the loading table; a finish machining numerical control lathe is arranged at a subsequent end of the rough machining numerical control lathe; the machining beats of the rough machining numerical control lathe and the finish machining numerical control lathe are five minutes; an automatic counting transfer conveying line is arranged at a subsequent end of the finish machining numerical control lathe; a machining center for drilling and tapping is arranged at a subsequent end of the automatic counting transfer conveying line; a joint loading and unloading manipulator is arranged on one side of the machining center; automatic dust removing equipment, an automatic detector and a packing device are arranged aroundthe joint loading and unloading manipulator in sequence; and a main control center is arranged on one side of the production line. The motor end cover intelligent production line can realize the operation through one-person multi-line and multi-machine intelligent cooperation, and is stable in quality, high in production efficiency, short in production period, high in safety, lower in human resource cost and intelligent in production.

Owner:SHANGHAI LONGDAY MACHINERY

Loading device for creep experiments of multi-specimen bonded joints

InactiveCN105115889BMeet the requirements of creep testGuaranteed reliabilityUsing mechanical meansMaterial analysisPull forceAdhesive

The invention discloses a loading device for creep experiments of multi-specimen bonded joints, which includes an upper loading plate and a lower loading plate, first to Nth bonding joints, a main loading lever and an arc-shaped lever. The first to Nth bonded joints are connected in series, one end of the main loading lever applies a pulling force, and the pulling force is sequentially loaded on the first to Nth bonding joints through the main loading lever and the arc lever, so that the tensile force of each bonding joint equal. The multi-specimen bonded joint creep test loading device of the present invention can simultaneously load multiple test piece bonded joints, thereby greatly shortening the test period and reducing the test cost. The arc-shaped lever and the lever support assembly are used to realize the series loading of the bonded test pieces. The force of each bonded test piece is equal and the direction is the same, and the total loading load is reduced to ensure the reliability of the experimental data.

Owner:JILIN UNIV

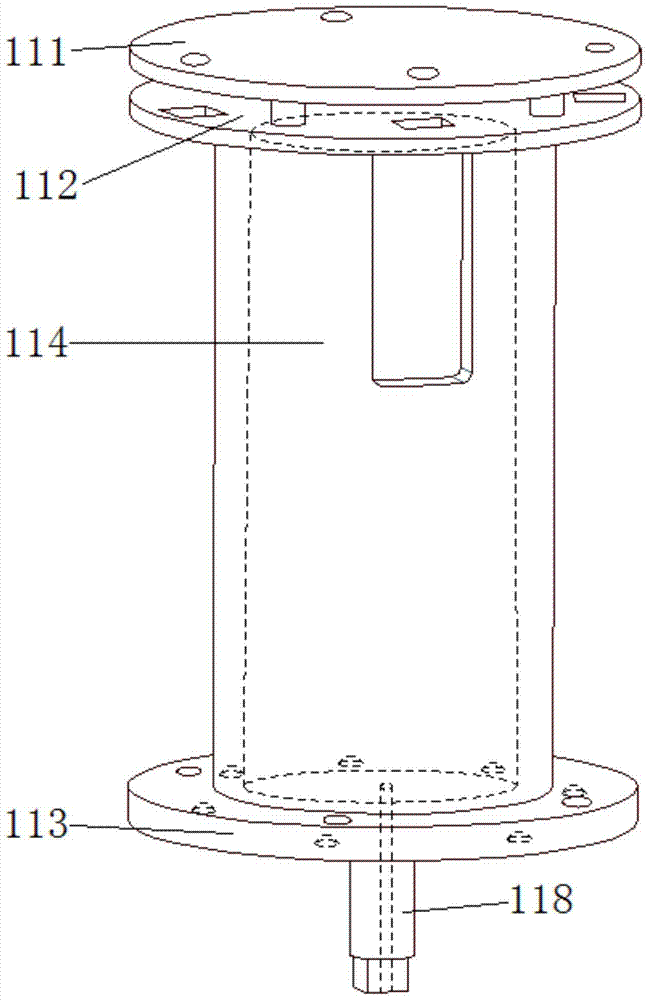

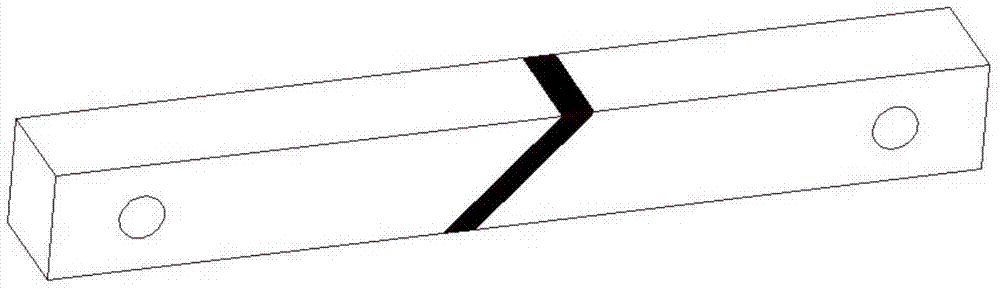

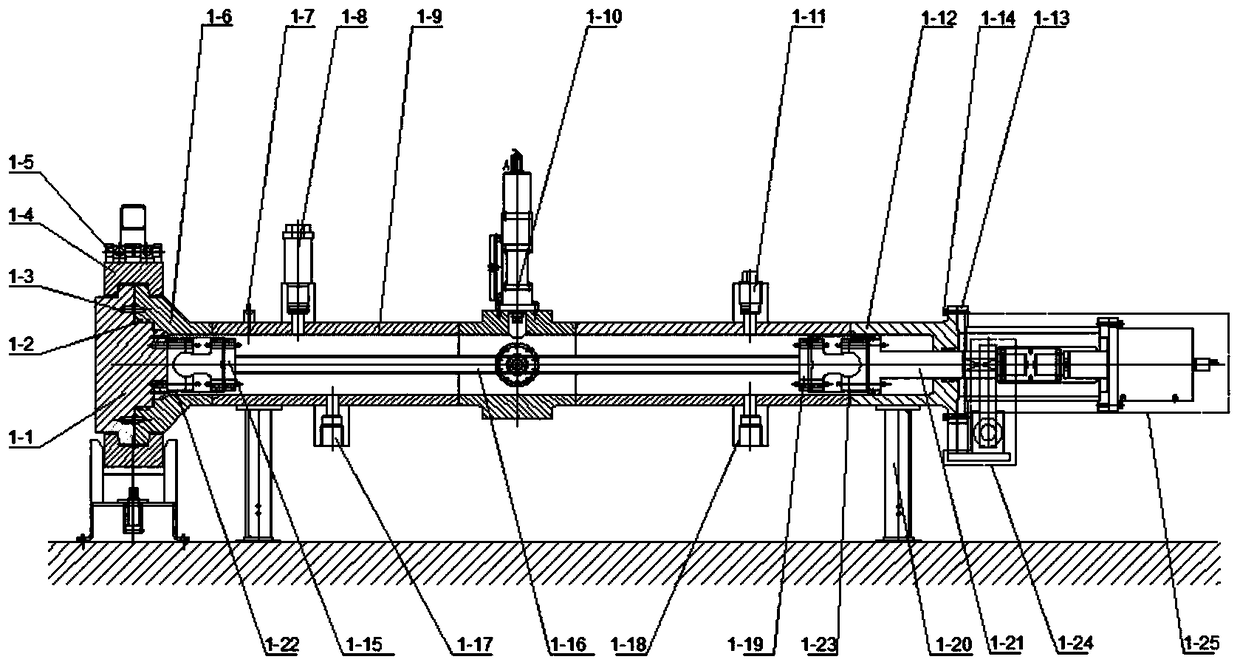

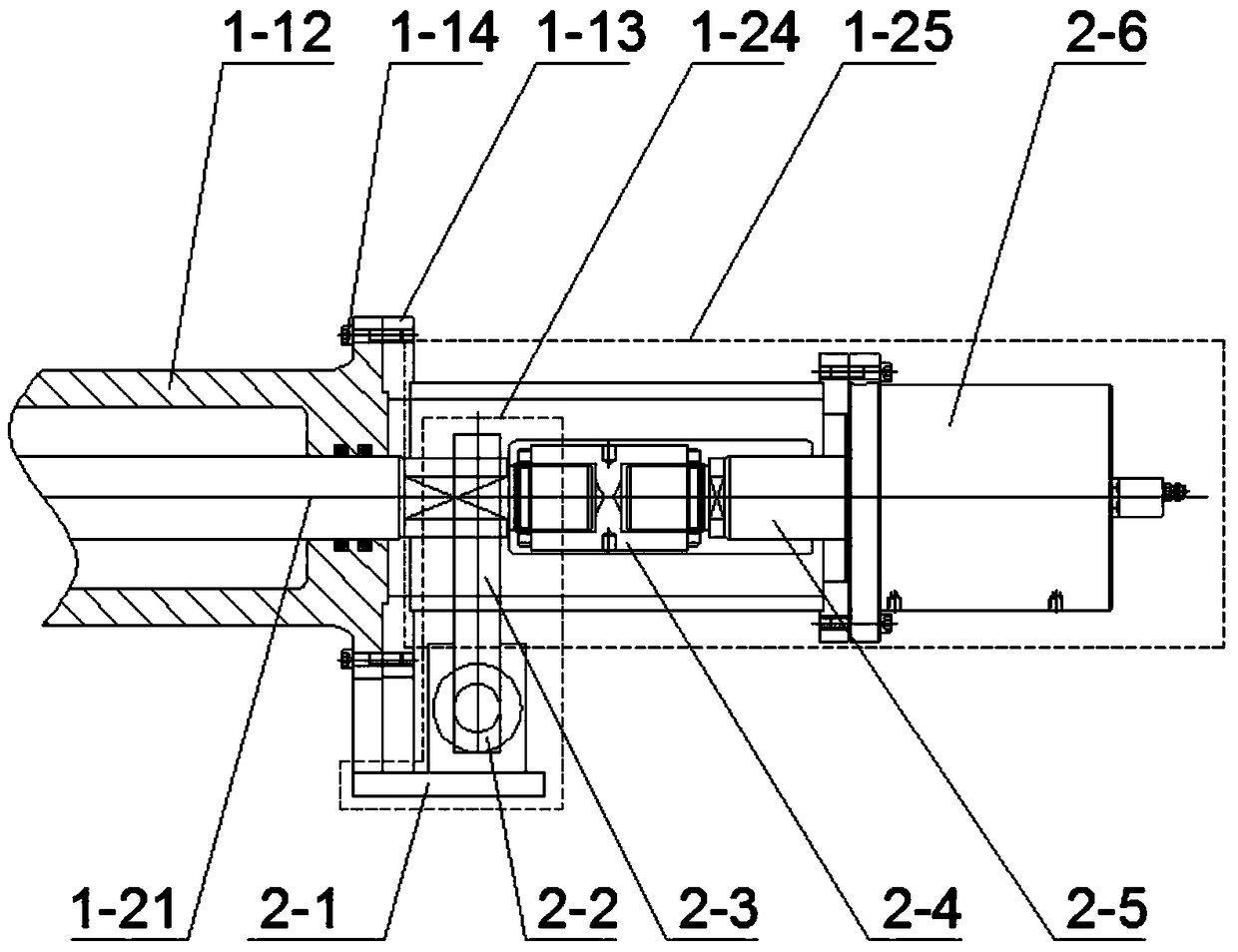

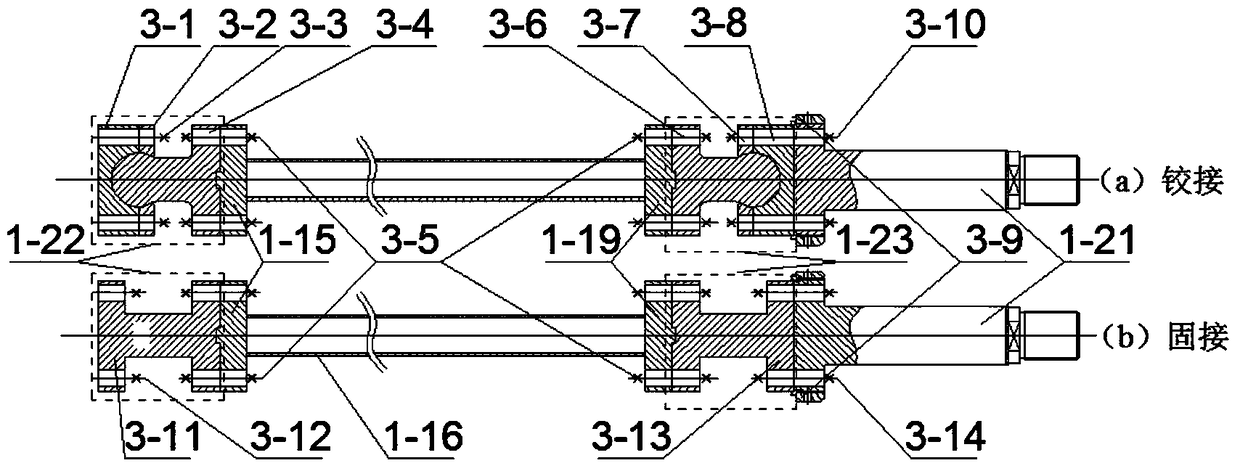

Submarine pipeline complex load joint loading test device

InactiveCN105806694BImplement security checksMeet the simulation needs of real working environmentStrength propertiesLand coverPipe fitting

The invention relates to a combined loading testing device for complex loads of submarine pipelines. The combined loading testing device comprises an end cover (1-1), a cylinder end part (1-6), a cylinder main body (1-5) and a cylinder tail (1-12), wherein a front-end sealing flange (1-15) and a tail-end sealing flange (1-19) are welded to two ends of a testing pipe fitting (1-16), respectively, holes are formed in the top and the side part of the cylinder main body (1-5), respectively, and vibrating devices (1-10) are mounted at the two holes and are used for applying vibrating loads to the testing pipe fitting along the radial direction; an axial force-torque combined loading device is connected to the cylinder tail (1-12) through a connecting assembly (1-13); the tail-end sealing flange (1-19) is connected with a connecting shaft (1-21) through a tail-end connecting assembly (1-23), and the connecting shaft (1-21) stretches out of a cylinder and is connected with the axial force-torque combined loading device. According to the combined loading testing device, the approximate simulation of deepwater pipelines and vertical pipes under different limiting conditional loads is provided.

Owner:TIANJIN UNIV

Multi-angle loading device for spine biomechanics measurement

InactiveCN106644539BEasy to operateStructural/machines measurementBiomedical engineeringWing loading

The invention discloses a spinal biomechanics measurement multi-angle loading device, which comprises a pedestal, an experiment table, a rotating and bending loader, a vertical loader, a front-and-back loader and a left-and-right loader, and is characterized in that the rotating and bending loader and the left-and-right loader have a clamping function and can perform effective fixation on a spinal creature, and each loader is driven by a motor to perform loading. The spinal biomechanics measurement multi-angle loading device can perform force loading on a spinal creature from six angles, and can realize separate loading and joint loading, thereby providing a basis for the study of the spinal biomechanics, and being simple in operation. The spinal biomechanics measurement multi-angle loading device is suitable for being widely applied in the technical field of medical instruments.

Owner:陈刚

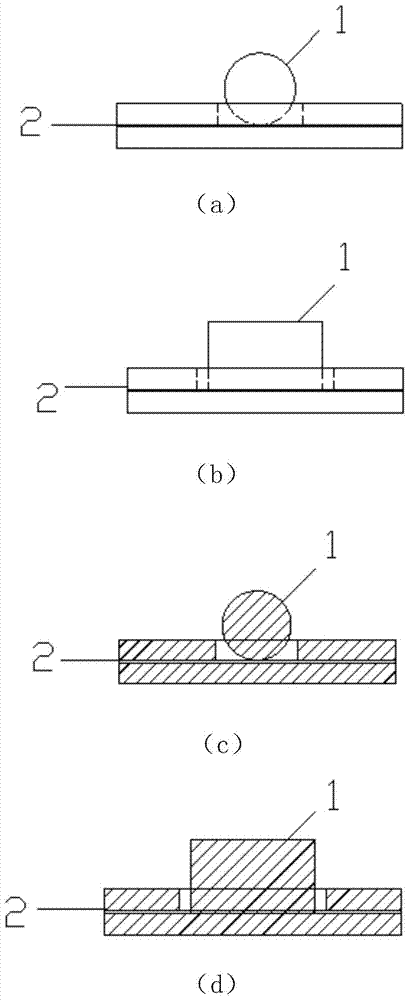

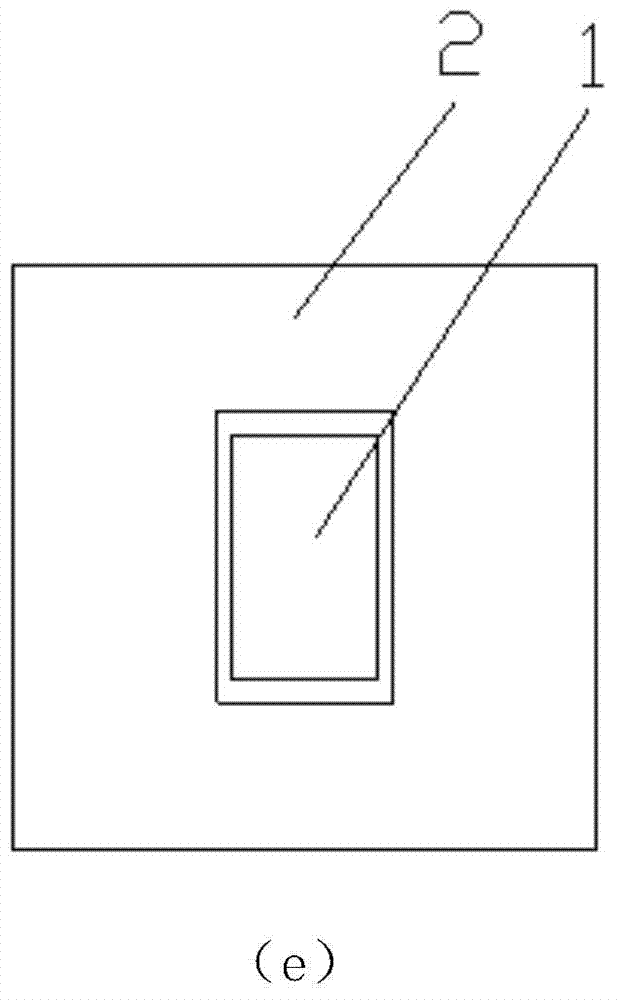

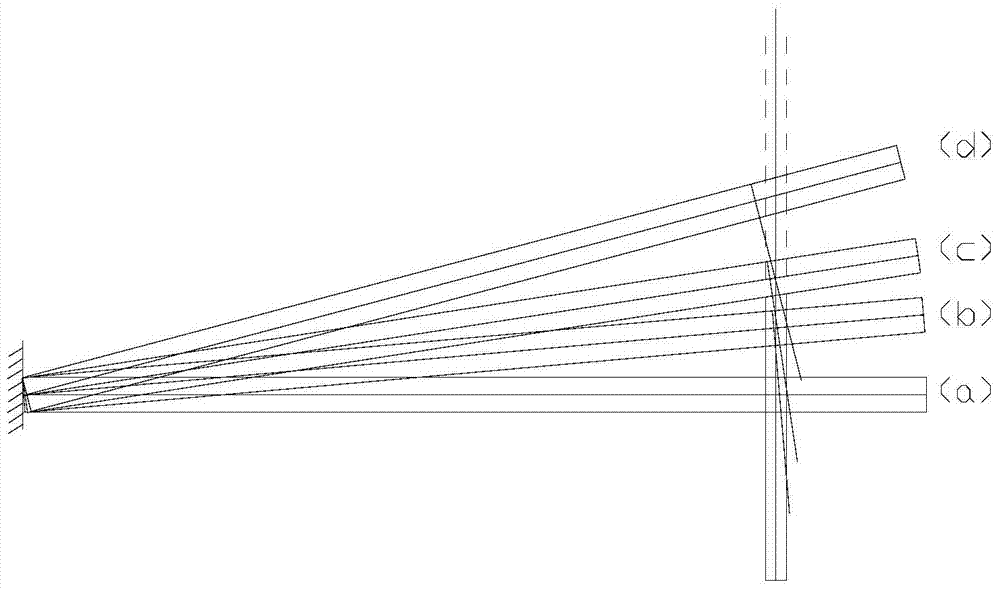

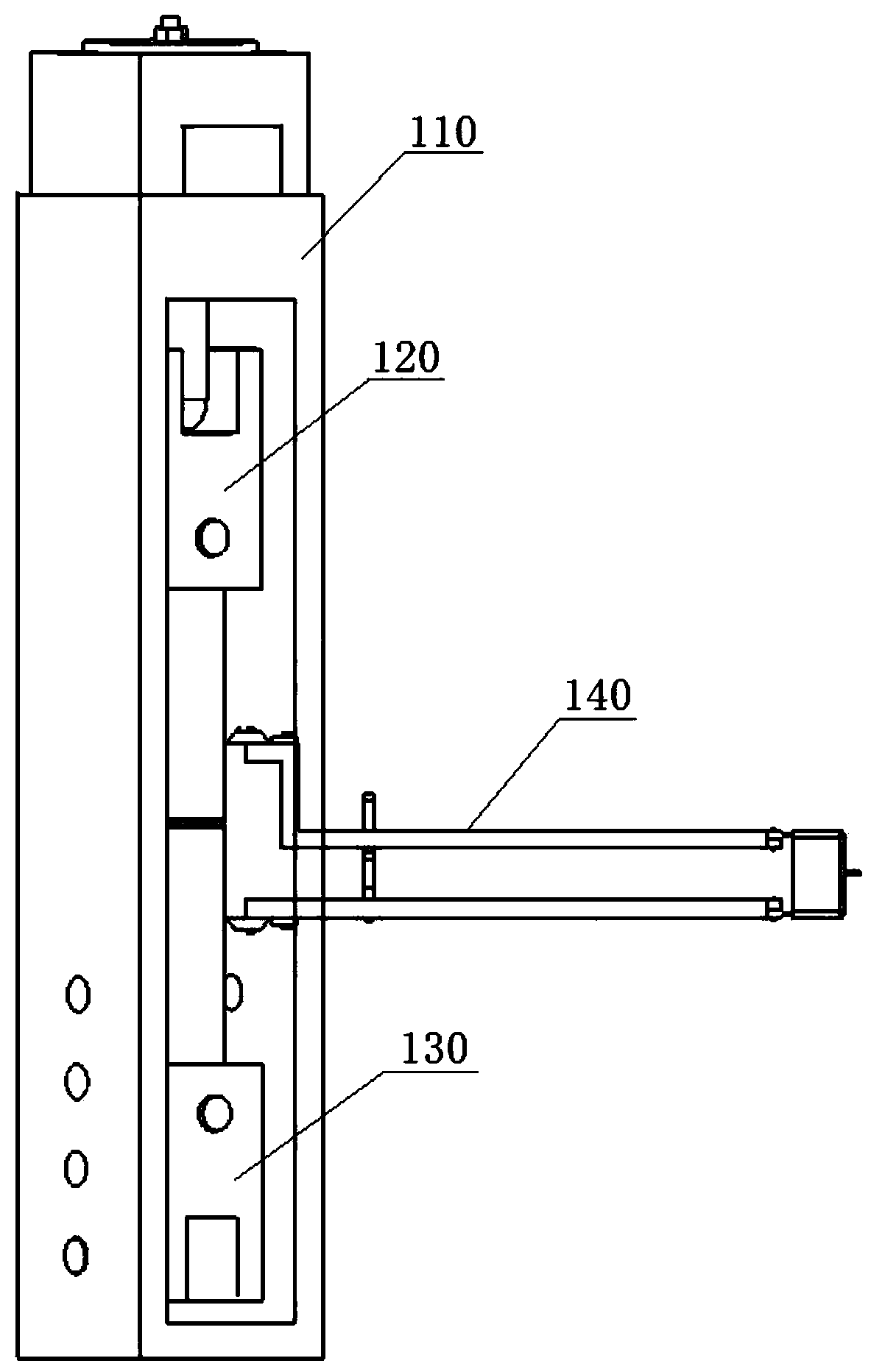

Joint loading method of cantilever structure

ActiveCN103674714AGuaranteed unchangedEasy and accurate meteringMaterial strength using tensile/compressive forcesEngineeringCantilever

The invention discloses a joint loading method of a cantilever structure. The joint loading method specifically comprises the following steps: step 1, manufacturing a loading joint; step 2, manufacturing a loading device; step 3, mounting the loading device in the cantilever structure: placing the loading device on a horizontal hardened concrete floor, adjusting the thickness of a sole plate or the quantity of a base plate to adjust the height of the loading device, enabling a rolling column to be in exact contact with the lower part of a member necessary to be applied with a force, and thereby supporting the loading device in the cantilever structure. By virtue of the method, when the component is displaced, the component is still in the tangential direction of the joint, only the position of the contact surface but not the area of the contact surface is changed, so that the contact surface is guaranteed to be invariant, and the force application direction is still perpendicular to the component. The applied force is completely exerted on the component, and the force stressed by the component can be simply, conveniently and accurately measured.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

An off-line loading method for weather resistance test of bonded joints

InactiveCN105136565BShorten the test cycleImprove experimental efficiencyWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesAdhesiveRoom temperature

The invention discloses an off-line loading method for an adhesive joint weather resistance test, comprising the following steps: Step 1: determining the maximum experimental load F of the adhesive joint during the experiment 0 , and set the maximum experimental load F 0 Divided into n levels, n is greater than or equal to 2, and the load of the i-th level is Step 2: Load the bonded joint offline to load F i stop loading; step 3: place the bonded joint together with the off-line loading device in the environmental box, and the temperature in the environmental box is cycled from high temperature, normal temperature to low temperature; step 4: remove the bonded joint, and carry out Tensile test, record the fracture load and fracture strain of the bonded joint; step 5: repeat steps 2 to 4, record the fracture load and fracture strain of the bonded joint under each load level from i to n, and draw the fracture parameter relationship curve. The invention can carry out off-line loading on multiple bonding test pieces at the same time, which greatly shortens the test period, improves the test efficiency and reduces the test cost.

Owner:JILIN UNIV

Cell Composite Force-Electrical Loading Measurement Device

InactiveCN103966091BImplement continuous loadingRealize the loadStress based microorganism growth stimulationEngineeringCell engineering

The invention belongs to the technical field of cell engineering, and particularly relates to a cytomechanic-electrical joint loading and analyzing device in a biomedical experimental instrument. The invention discloses a device for cell composite force-electric load measurement. The device comprises a mechanical drive system, a mechanical drive control system, an electrode probe, a cell placement platform, an electric signal generation system and a piezoelectric measurement system. The invention also discloses a device for cell composite force-electric load measurement. The device for cell composite force-electric load measurement comprises a mechanical drive system, a mechanical drive control system, an electrode probe, a cell placement platform, an electric signal measuring system and a piezoelectric measurement system. The devices disclosed by the invention are applied to an application prospect for cytomechanic-electrical load measurement on cells.

Owner:XIAMEN UNIV

A measuring device for plane frame node loading and node area shear deformation

ActiveCN106153314BEasy to installPrevent twistingMachine part testingAxial forceShearing deformation

The invention provides a planar frame joint loading and joint region shear deformation measuring device. The planar frame joint loading and joint region shear deformation measuring device comprises an axial self-balancing reaction frame, a horizontal loading reaction frame and two-force pole supporting frames. An axial force is applied to a joint test-piece through the axial self-balancing reaction frame until the axial force achieves a preset value; the two-force pole supporting frames are symmetrically arranged at two ends of the cross beam of the joint test-piece and are hingedly connected with the cross beam and support the cross beam firmly; and the horizontal loading reaction frame, adopted as a loading device, provides a lateral loading force for the joint test-piece, so that the joint test-piece can go through shear deformation. According to the planar frame joint loading and the joint region shear deformation measuring device of the invention, the axial force is applied through a self-balancing manner, so that error caused by the application of a large axial force by adopting a traditional joint device or an MTS or a jack can be eliminated. Compared with a traditional joint loading device, the planar frame joint loading and joint region shear deformation measuring device has the advantages of easier implementation, convenience in the control of column end loading, high test precision and small occupied space, and can be used for performance testing of joints in a plane and edge joints, and is especially applicable to seismic performance testing of various kinds of joints of planar frames.

Owner:CHONGQING UNIV

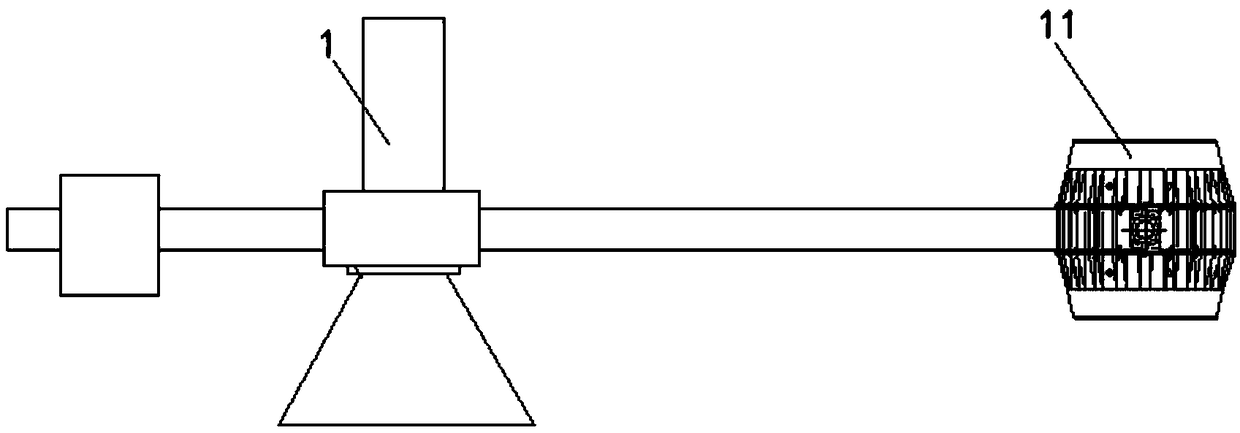

A Test System for Testing the Fatigue Performance of Helicopter Main Propeller Girder

ActiveCN104019967BEasy to operateHigh measurement accuracyMachine part testingElectric machineEngineering

A test system for testing the fatigue performance of the helicopter main propeller girder, which consists of a helicopter main propeller girder root specimen, a process joint, a loading joint, a test bench, a vibration exciter, a motor, an electric control cabinet, a hydraulic system, a hydraulic control cabinet, a strain One end of the helicopter main propeller girder specimen is installed on the process joint; the process joint is installed on the test bench; the other end of the helicopter main propeller girder specimen is installed on the loading joint; It is connected with the loading joint and installed on the test bench; the motor is connected with the exciter and the electric control cabinet; the hydraulic system is connected with the loading joint and the hydraulic control cabinet; the strain gauge is pasted on the corresponding position of the helicopter main rotor girder test piece; the dynamic strain The instrument is connected with the strain gauge; the optical oscilloscope is connected with the dynamic strain gauge. The invention has simple structure and convenient operation, and is used for the fatigue performance test of the main propeller girder of the helicopter, and the test result has important engineering application value for the evaluation of the fatigue life of the structure.

Owner:北京堂仁翔科技有限公司

Automatic electric water heater apparatus

InactiveCN107394454AAvoid Electric Shock AccidentsRealize automatic isolationFluid heatersLive contact access preventionElectricityAutomatic control

The invention discloses an automatic electric water heater device, which comprises an electric water heater and an electric connection device. The connection terminal and the connection pin composed of the entry part and the connection part, the installation part is fixed on the upper left side of the connection part, the bottom end surface of the installation part is provided with a slide rail groove, and the left and right extensions are arranged in the slide rail groove. The first screw rod is set, the left end of the first screw rod is connected with the first electric rotating machine, the right end of the first screw rod is connected with the inner end of the right side of the slide rail groove in running cooperation, and the first screw rod is provided with a screw fit connection The connection loading block under the first screw rod is provided with a loading horizontal bar extended to the right on the right end surface of the connection loading block under the first screw rod; the invention has a simple structure, can realize automatic connection and insertion, and can automatically control The exposed and concealed work of the connecting piece improves work efficiency and safety.

Owner:宁波鄞州启航工业产品设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com