Submarine pipeline complex load joint loading test device

A technology of combined loading and complex loading, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of single external load, inability to realize local stability test, and inability to realize the joint action of multiple loads, and achieve safety calibration. nuclear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the specific embodiment of the present invention will be further described:

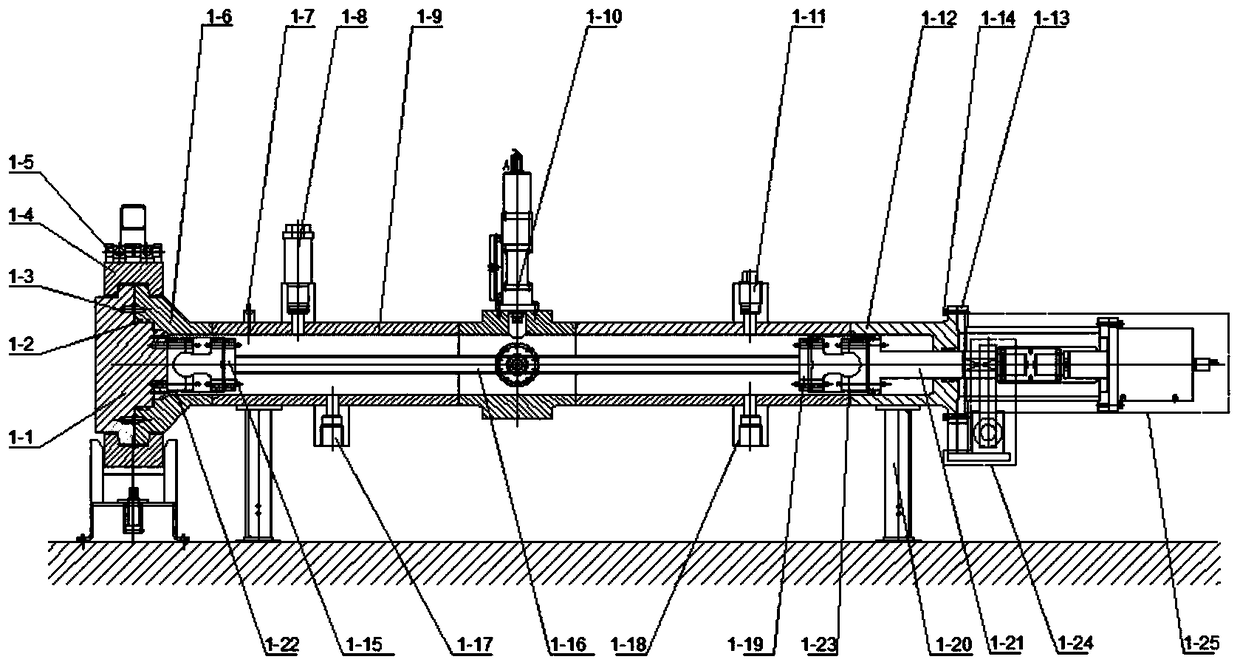

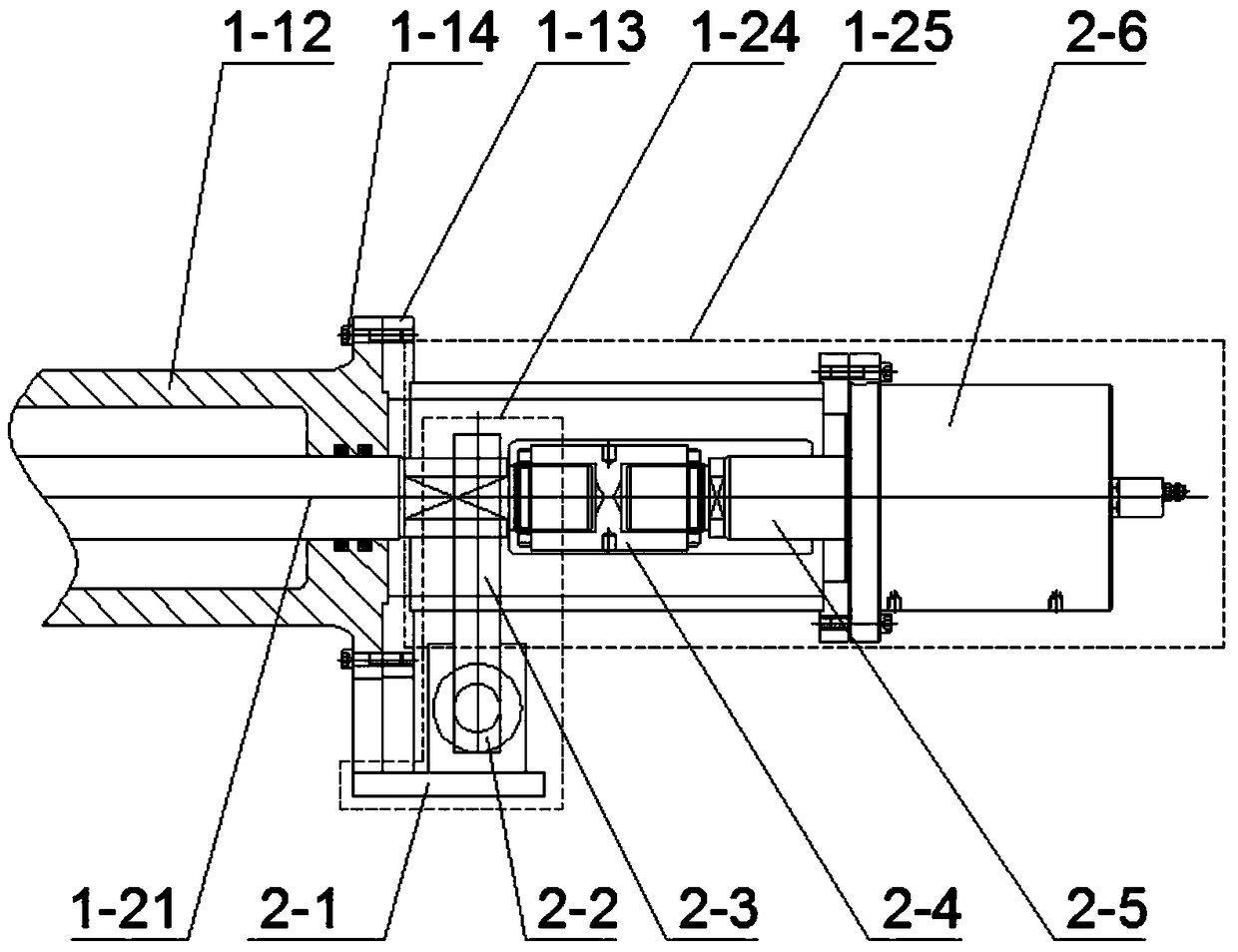

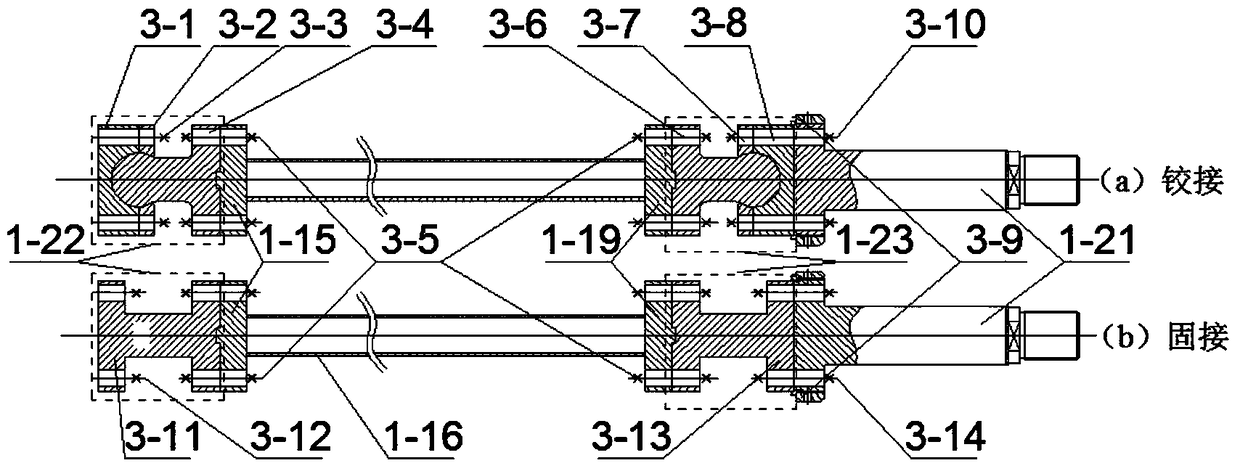

[0036] Such as figure 1 As shown, the combined loading buckling test device of the scale deep-water submarine pipeline mainly includes: end cover 1-1, cylinder end 1-6, cylinder main body 1-5, cylinder tail 1-12 and cylinder body The axial force-torque combined loading device connected at the tail is composed of a torque loading device 1-24 and an axial force loading device 1-25. The whole cylinder part is fixed on the ground by the saddle 1-20. The front end of the cylinder is closed by setting the positioning pin 1-3 and the clamp 1-4, and the sealing ring 1-2 keeps the seal. The cylinder body is provided with several openings, including a safety valve 1-8, a water injection port 1-17, a drainage hole 1-18, an exhaust hole 1-11 and a pressurizing hole 1-7. The middle part of the device is provided with two openings on the top and the side, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com