Preparation method of sodium alginate/inorganic mineral joint-loaded nanometer zero-valent iron

A nano-zero-valent iron, inorganic mineral technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low material recycling rate, the pore size of embedded beads and the mechanical strength to be improved, etc. The effect of effluent quality and reuse rate, improving reuse rate and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

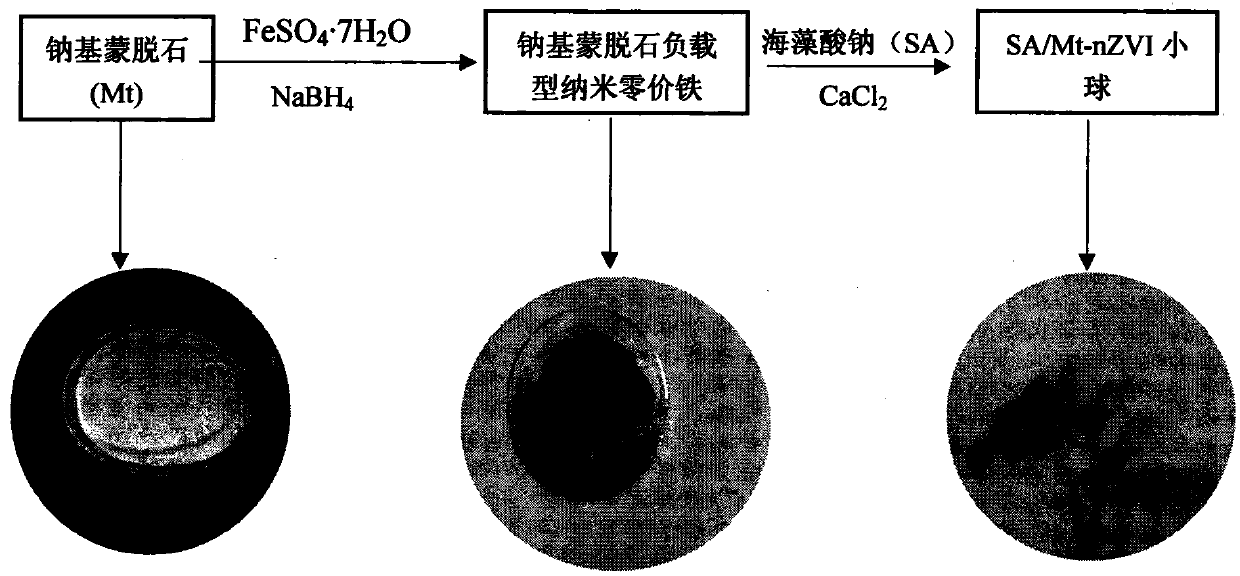

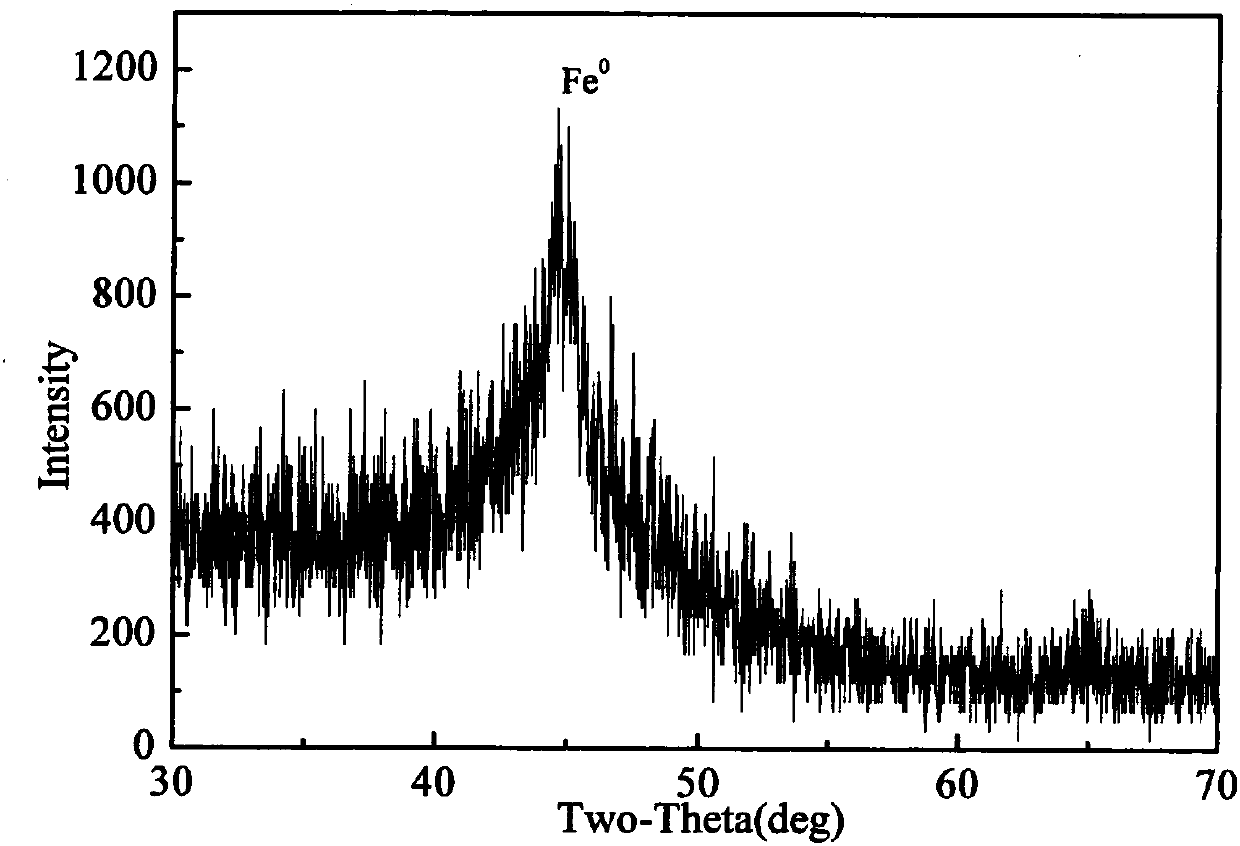

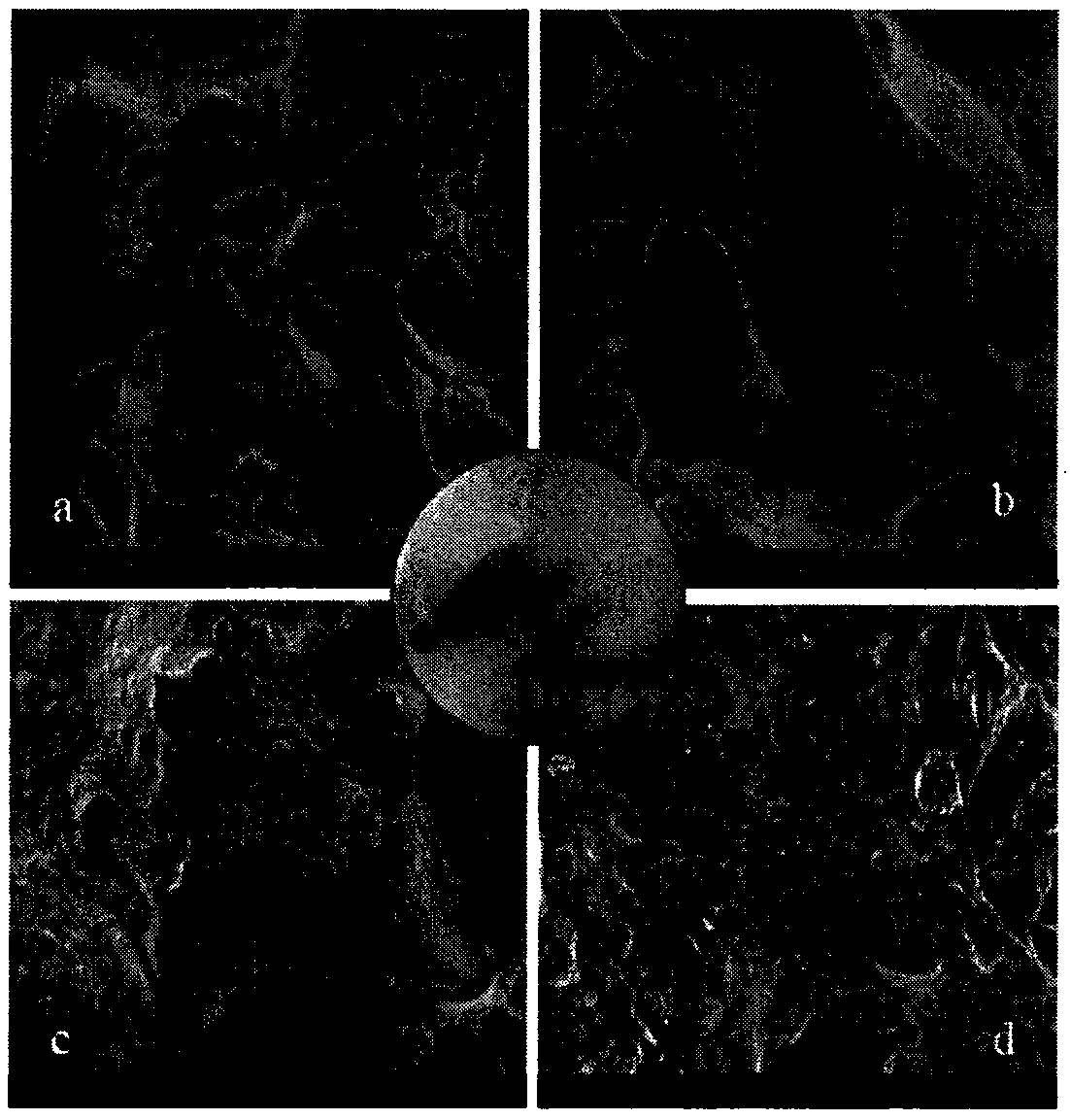

[0040] A kind of preparation method of sodium alginate / inorganic mineral combined loading type nanometer zero valent iron, such as figure 1 As shown, the specific steps are:

[0041] Step 1: Under the protection of nitrogen, use the liquid phase reduction method to combine inorganic minerals and FeSO 4 ·7H 2 O mixed to prepare inorganic mineral-supported nanometer zero-valent iron, the specific steps are: under the protection of nitrogen, take 24.88g FeSO 4 ·7H 2 O was dissolved in 200ml of ethanol-water solution with a volume ratio of 4:1 and then added to a 500ml three-necked flask to obtain FeSO 4 solution. Add 20g of Na-montmorillonite (Mt) to the above FeSO 4 solution, stirred for 30min to make it fully mixed to obtain FeSO 4 -Mt mixture. 50mlNaBH 4 The solution is placed in a constant pressure funnel, where the BH 4 - and FeSO 4 - Fe in inorganic mineral mixture2+ The molar ratio was 3:1, FeSO was added dropwise 4 -Mt mixed solution, the drop rate is 2 drops / ...

Embodiment 2

[0049] Similar to Example 1, the difference is that the mass concentration of the sodium alginate solution prepared in step 2 is 1%, 1.5%, 3%, and in step 3, the sodium-based montmorillonite-loaded nanometer zero-valent iron The mass concentration is 2%, 4%, 6%. The corresponding sodium alginate / sodium-based montmorillonite joint-loaded nanometer zero-valent iron was prepared.

Embodiment 3

[0051] Similar to Example 1, the difference is that in Step 3, the mass concentration of Na-montmorillonite-supported nano-ZVI is 2% and 4%. The corresponding sodium alginate / sodium-based montmorillonite joint-loaded nanometer zero-valent iron was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com