An off-line loading method for weather resistance test of bonded joints

A weather-resistant, off-line technology, applied in the directions of weather resistance/light resistance/corrosion resistance, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc. problems, to achieve the effect of shortening the test cycle, reducing the cost of the experiment, and improving the efficiency of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

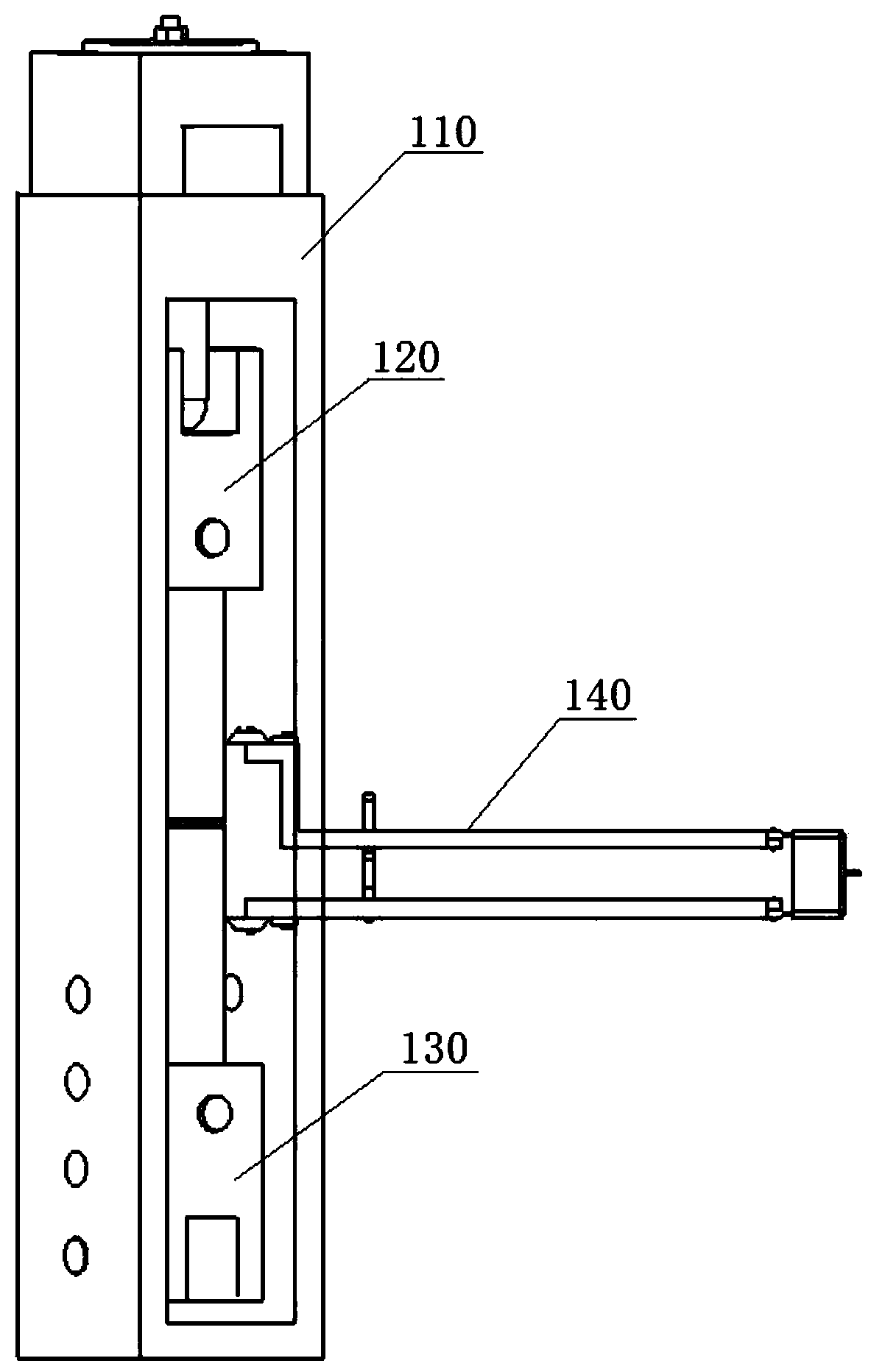

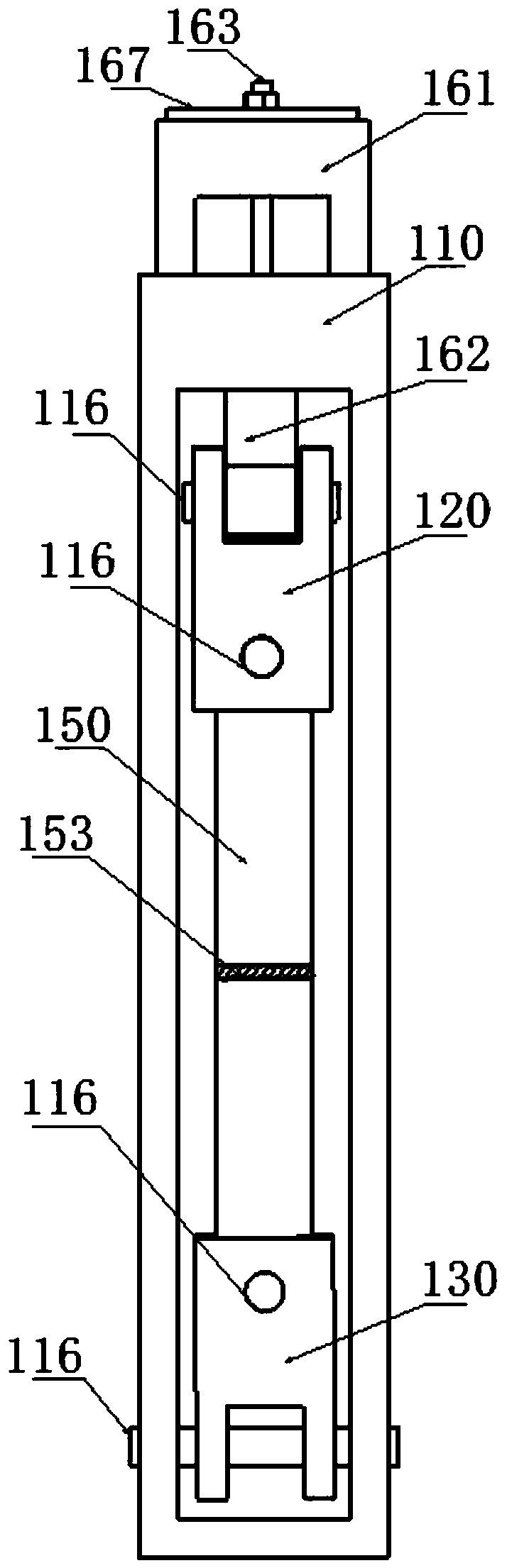

[0041] Such as figure 1 , figure 2 As shown, the present invention provides an off-line loading device for the weather resistance test of bonded joints, including a main frame 110 , an upper double U-shaped connector 120 , a lower double U-shaped connector 130 , a loading device and an extensometer 140 .

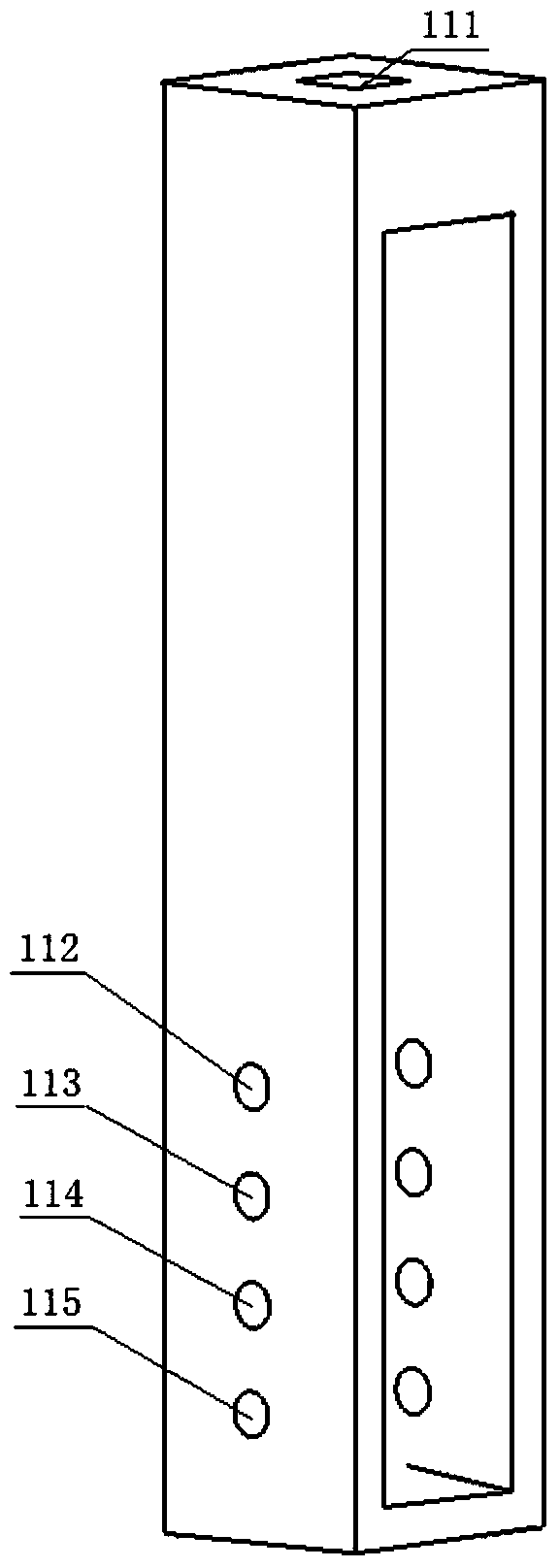

[0042] Such as image 3 As shown, the main frame 110 is set as a hollow frame, that is, the main frame 110 is provided with four sides, upper, lower, left, and right, without two front and back sides, and the middle part is hollow. The main frame 110 is 334mm long, 65mm wide, and 60mm high. The frame thickness on both sides is 10mm. The top of the main frame 110 is provided with a square guide hole 111. The side length of the guide hole 111 is 18.5mm, and the hole depth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com