Assembling machine for multiple types of pipe joints

A technology for pipe joints and assembly machines, which is applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of small use range and low assembly efficiency, and achieve the effect of improving assembly efficiency and simplifying manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

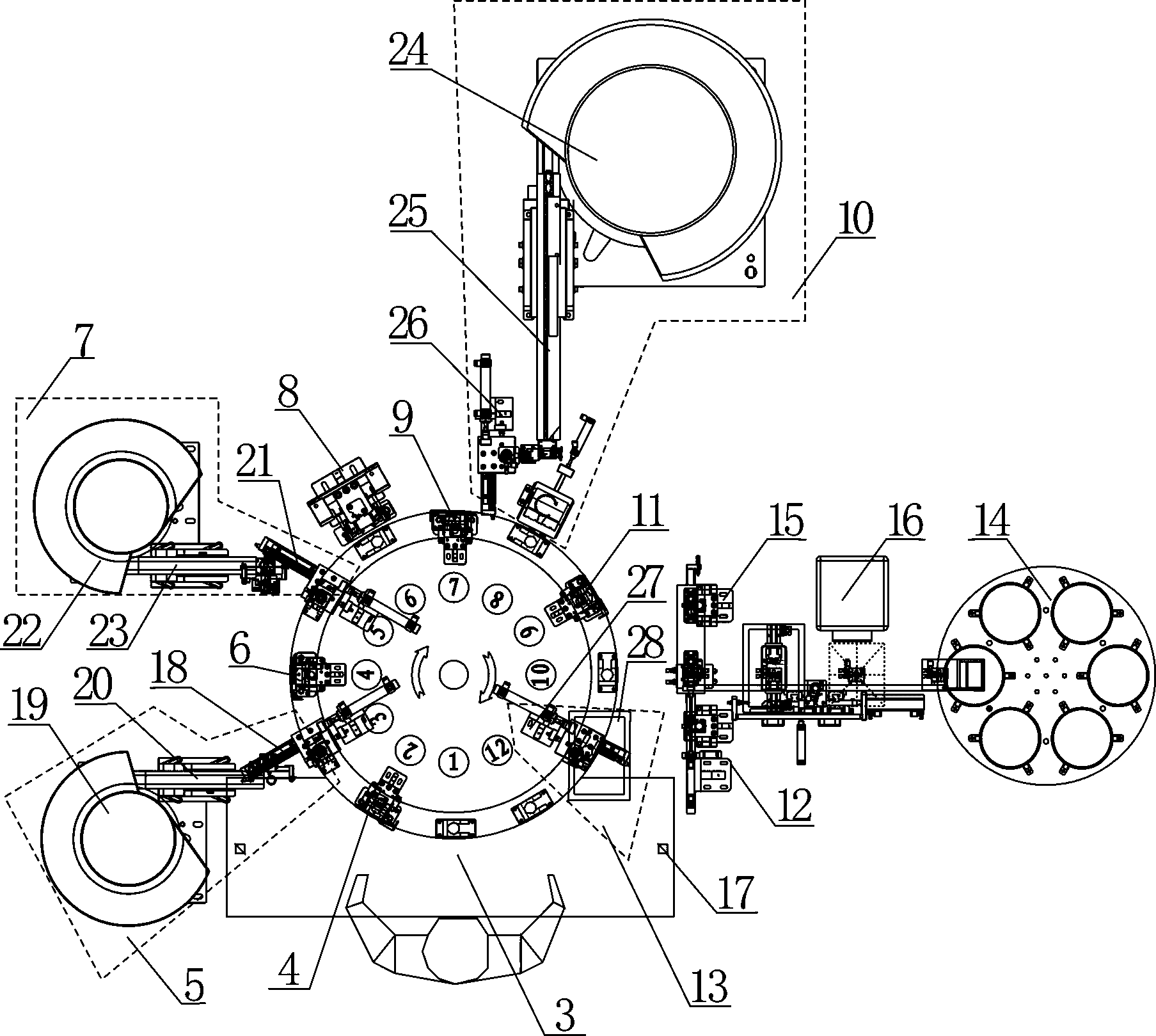

[0020] Such as figure 1 As shown, the multi-type pipe joint assembly machine includes an intermittent turntable 1, and twelve jigs 2 are evenly distributed on the intermittent turntable 1 along its periphery. Joint body manual loading station 3, foreign matter detection device in pipe joint body 4, sealing ring loading and loading device 5, sealing ring in-position detection device 6, safety ring feeding and loading device 7, safety ring pressing device 8 , safety ring press-in detection device 9, lock spring feeding and loading device 10, lock spring loading detection device 11, multi-grabbing manipulator 12 and assembly defective product removal device 13, one side of multi-grabbing manipulator 12 is provided in sequence An air tightness detection device 15, a laser coding machine 16 and a packing turntable 14.

[0021] A safety grating 17 is provided at the 3rd position of the manual loading station of the pipe joint body, and the pipe joint body is manually put into the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com