Loading device used for space fabricated type semi-rigid joint test

A loading device and assembled technology, which is applied in the direction of measuring device, testing material strength by applying stable bending force, testing material strength by applying stable tension/compression, etc., can solve the problem of joint loading of axial force and bending moment, etc. problem, to achieve the effect of balanced tension, practicality and flexibility, and large measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

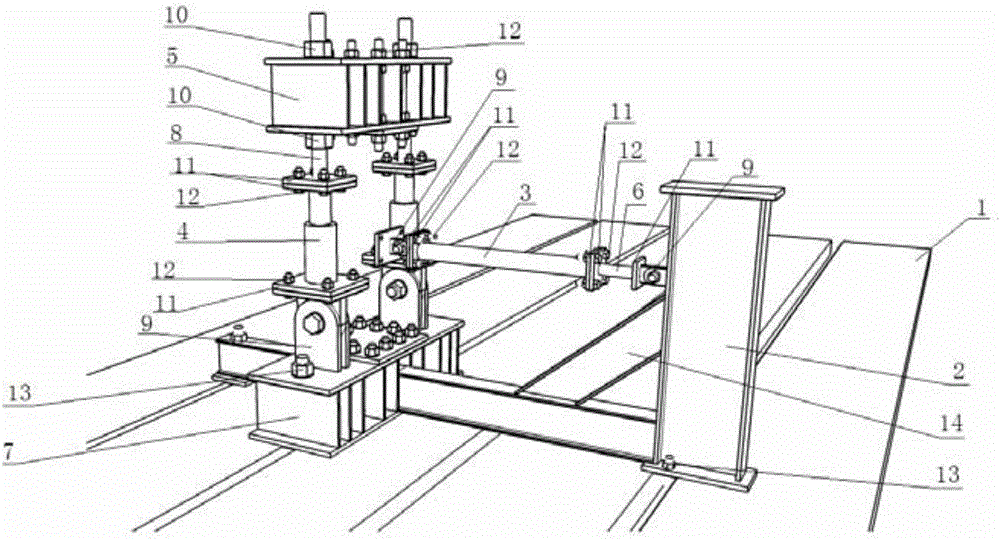

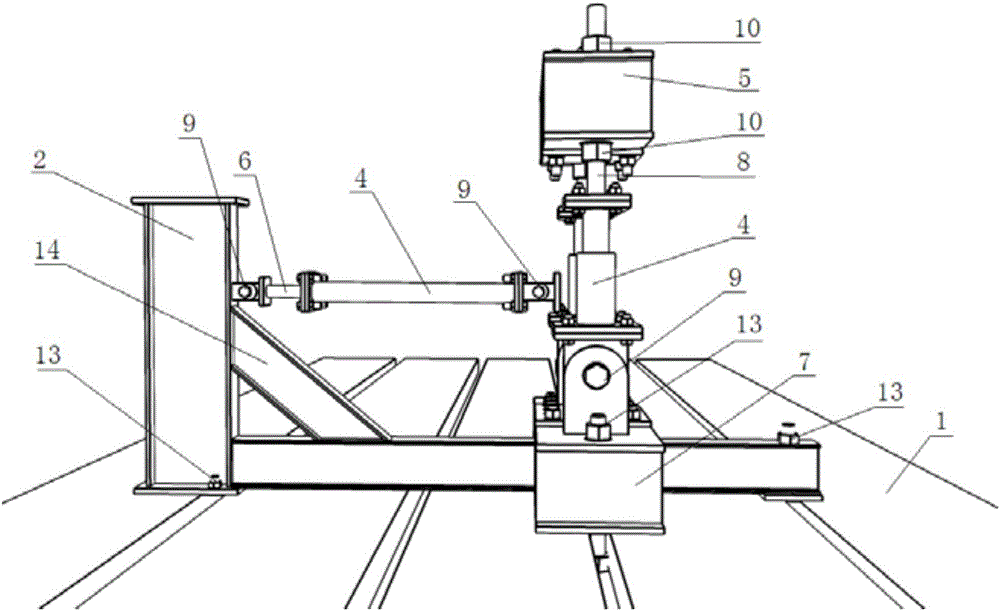

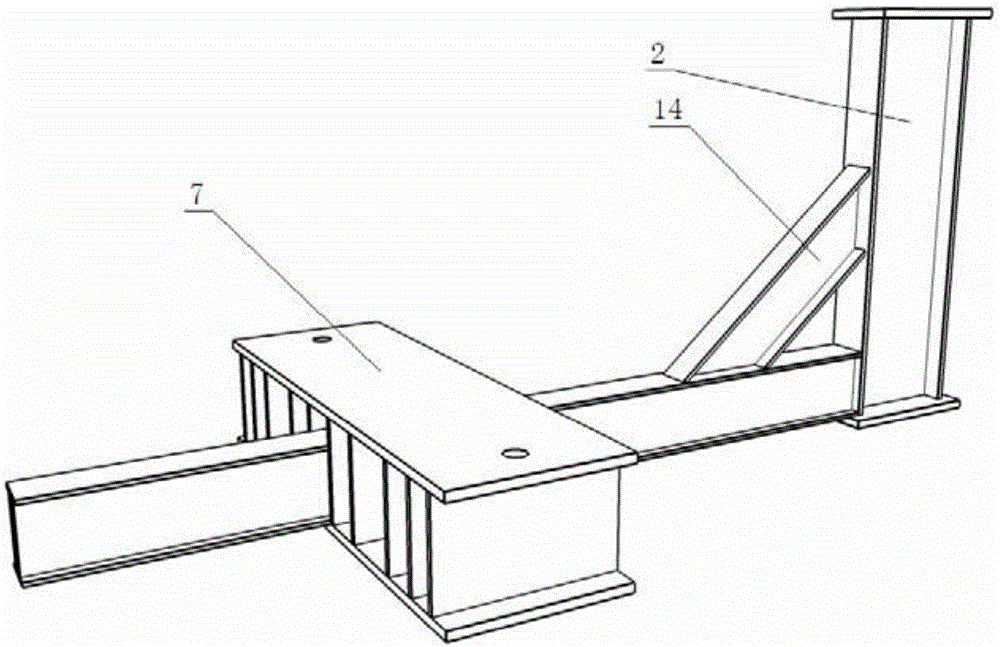

[0014] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment mode, a kind of loading device that is used for space-assembled semi-rigid joint test in this embodiment mode includes L-shaped reaction force frame 2, horizontal hydraulic jack 3, fixed frame 7, reaction force beam 5 and two vertical The hydraulic jack 4, the L-shaped reaction frame 2 is vertically fixed on the upper surface of the trough 1, the horizontal end of the L-shaped reaction frame 2 is vertically fixed with a fixed frame 7, and the upper end of the fixed frame 7 is provided with a reaction beam 5 , two vertical hydraulic jacks 4 are arranged in parallel between the fixed frame 7 and the reaction beam 5, the lower end of the vertical hydraulic jack 4 is rotatably connected with the upper end surface of the fixed frame 7 through a hinge mechanism 9, and the upper end of the vertical hydraulic jack 4 An anchor rod 8 is fixedly connected, the upper end of the anchor rod 8 is ...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 , figure 2 with Figure 4 Describe this embodiment, the upper end of the anchor rod 8 in this embodiment is vertically inserted on the reaction beam 5 , and the upper and lower ends of the reaction beam 5 are fixedly connected to the anchor rod 8 through lock nuts 10 . Other compositions and connection methods are the same as those in Embodiment 1.

[0017] This design makes the reaction beam 5 slide along the length direction of the anchor rod 8, and after reaching the predetermined position, the position of the reaction beam 5 is locked and fixed by the lock nut 10, so that the position of the reaction beam 5 meets the requirements of different node heights. The loading scheme is flexible in practicability, and is suitable for the test of studying the mechanical properties of the assembled semi-rigid joint under the joint action of axial force and bending moment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 , figure 2 with Figure 5 This embodiment will be described. A force sensor 6 is provided between the front end of the horizontal hydraulic jack 3 and the hinge mechanism 9 in this embodiment. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

[0019] Such a design can monitor the magnitude of the applied force in the horizontal direction in real time and accurately control the time shear force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com