Motor end cover intelligent production line

An intelligent production, motor-end technology, applied in metal processing machinery parts, other manufacturing equipment/tools, large fixed members, etc., can solve the problems of low production efficiency and slow production rhythm, and achieve high production efficiency, short production cycle and safety. high performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

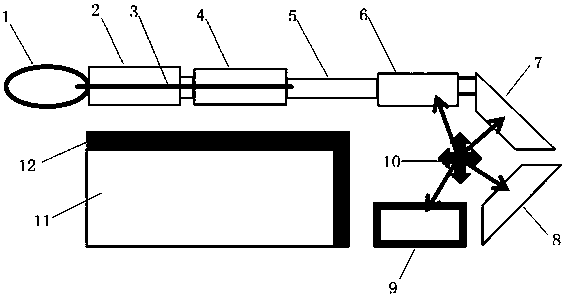

[0019] see figure 1 , in an embodiment of the present invention, an intelligent production line for motor end caps, including a feeding table 1, a rough machining CNC lathe 2, a truss manipulator 3, a finishing CNC lathe 4, an automatic counting and transfer conveyor line 5, a machining center 6, Automatic dust removal equipment 7, automatic detection machine 8, packaging device 9, articulated loading and unloading manipulator 10, master control center 11, safety passage 12, the loading platform 1 is the initial end of the production line, and the loading platform 1 is an ellipse Shaped feeding table, the subsequent end of the feeding table 1 is provided with a rough machining CNC lathe 2, and the subsequent end of the rough machining CNC lathe 2 is provided with a finishing CNC lathe 4, and the rough machining CNC lathe 2 and finishing The processing cycle of the CNC lathe 4 is five minutes, and the subsequent end of the finishing CNC lathe 4 is provided with an automatic cou...

Embodiment 2

[0029] The difference between this embodiment and embodiment 1 is:

[0030] A truss manipulator 3 is provided directly above the stations of the loading table 1, the rough machining CNC lathe 2, the finish machining NC lathe 4, and the automatic counting transfer conveyor line 5, and the truss manipulator 3 can vertically grasp the blank. A manipulator device with horizontal fixed track movement;

[0031] Tool racks, spare fixtures for numerical control equipment, spare manipulator fixtures, spare knives and spare measuring tool accessories are placed in the master control center 11 , and safety passages 12 are provided around the master control center 11 .

[0032] The working principle of the present invention is: the various accessories placed inside the master control center 11 can facilitate the replacement and maintenance of production line parts in the later stage, and the safety passages 12 set around the master control center 11 can facilitate the operator to monitor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com