Hydraulic type torsion connection simulator

A simulator and hydraulic technology, which is applied in the field of hydraulic torque connection simulators, can solve the problems of increasing calibration workload and labor intensity, increasing costs, etc., and achieve the effect of low cost, cost reduction and exquisite design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

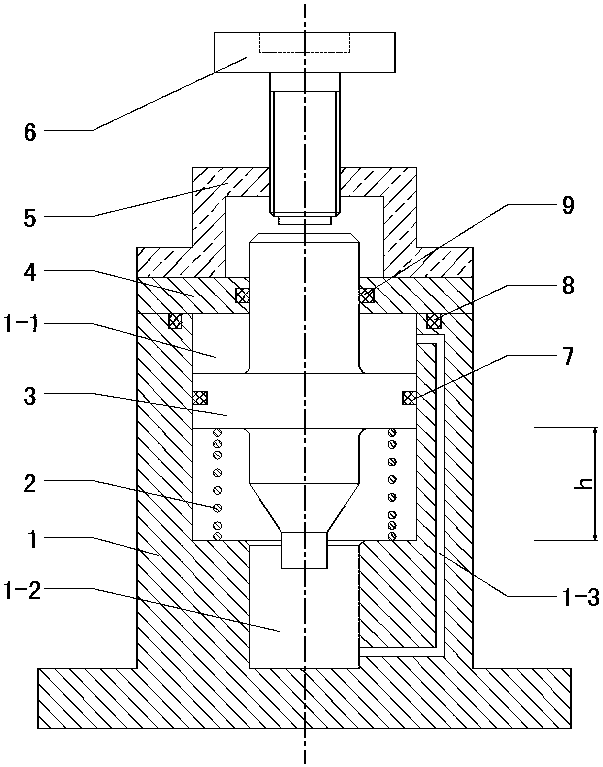

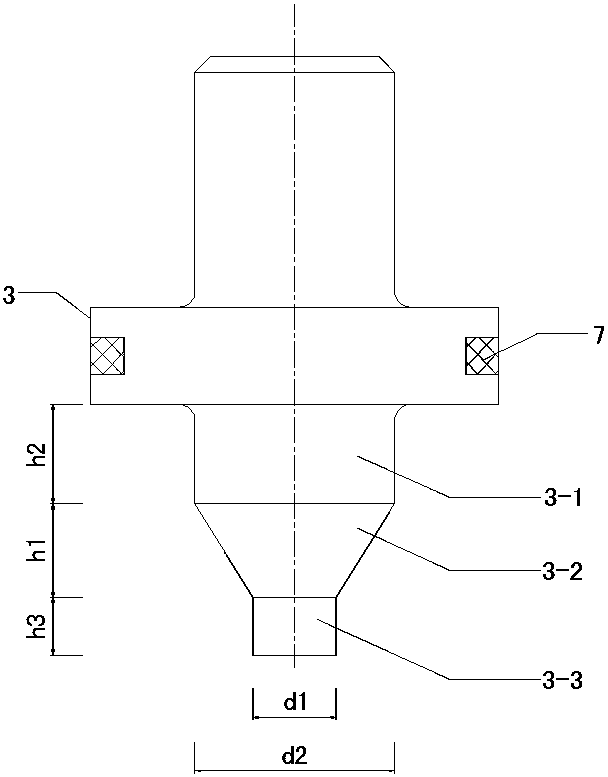

[0012] Specific implementation mode one: as Figure 1~Figure 2 As shown, the present invention discloses a hydraulic torque connection simulator, comprising a simulator hydraulic cylinder 1, a piston return spring 2, a piston rod, a cylinder upper cover 4, an upper cover 5 and a threaded loading joint 6, the The piston rod is composed of a coaxial and integrated upper piston rod, a piston 3, a large diameter round rod 3-1, a transitional truncated body 3-2 and a small diameter round rod 3-3 from top to bottom. The combination of the large-diameter round rod 3-1, the transition circular platform body 3-2 and the small-diameter round rod 3-3 constitutes the lower piston rod, and the center of the top surface of the simulator hydraulic cylinder 1 is provided with a stepped cylindrical chamber. The stepped cylindrical chamber includes a large-diameter cylindrical cavity 1-1 and a small-diameter cylindrical cavity 1-2 connected up and down, and the piston 3 is tightly plugged in th...

specific Embodiment approach 2

[0013] Specific implementation mode two: as figure 2 As shown, this embodiment is a further description of Embodiment 1. The diameter of the small-diameter round rod 3-3 is d1, and the diameter of the large-diameter round rod 3-1 is d2, d1² / d2² =1 / 10.

specific Embodiment approach 3

[0014] Specific implementation mode three: as Figure 1~Figure 2 As shown, this embodiment is a further description of Embodiment 1. The height of the transitional frustum 3-2 is h1, the height of the large-diameter round rod 3-1 is h2, and the small The height of the diameter round rod 3-3 is h3, the height of the small-diameter cylindrical inner cavity 1-2 is greater than h1+h3, the free height of the piston return spring 2 is h, h is greater than h1+h2, and the piston resets The compressible amount of spring 2 is greater than h-h2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com