Drill bit with circumferential rotary impulse

A drill bit and thrust technology, applied in the field of drilling, can solve the problems of low screw life, high cost, and unsatisfactory use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

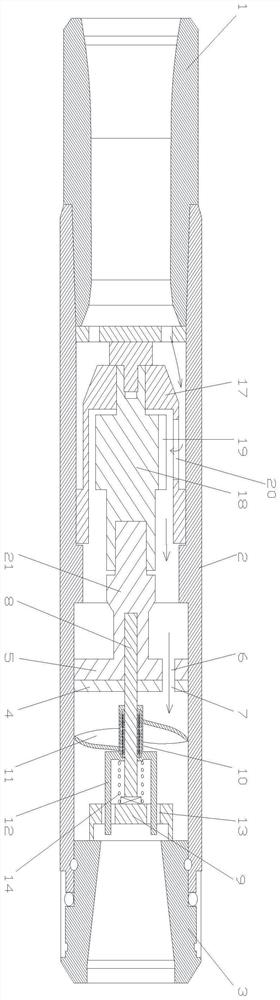

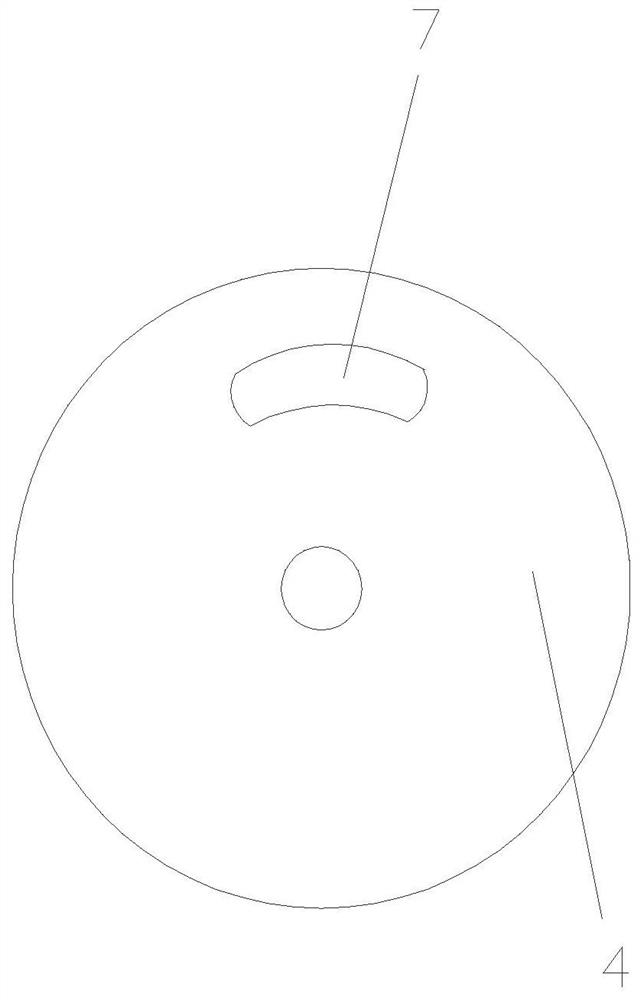

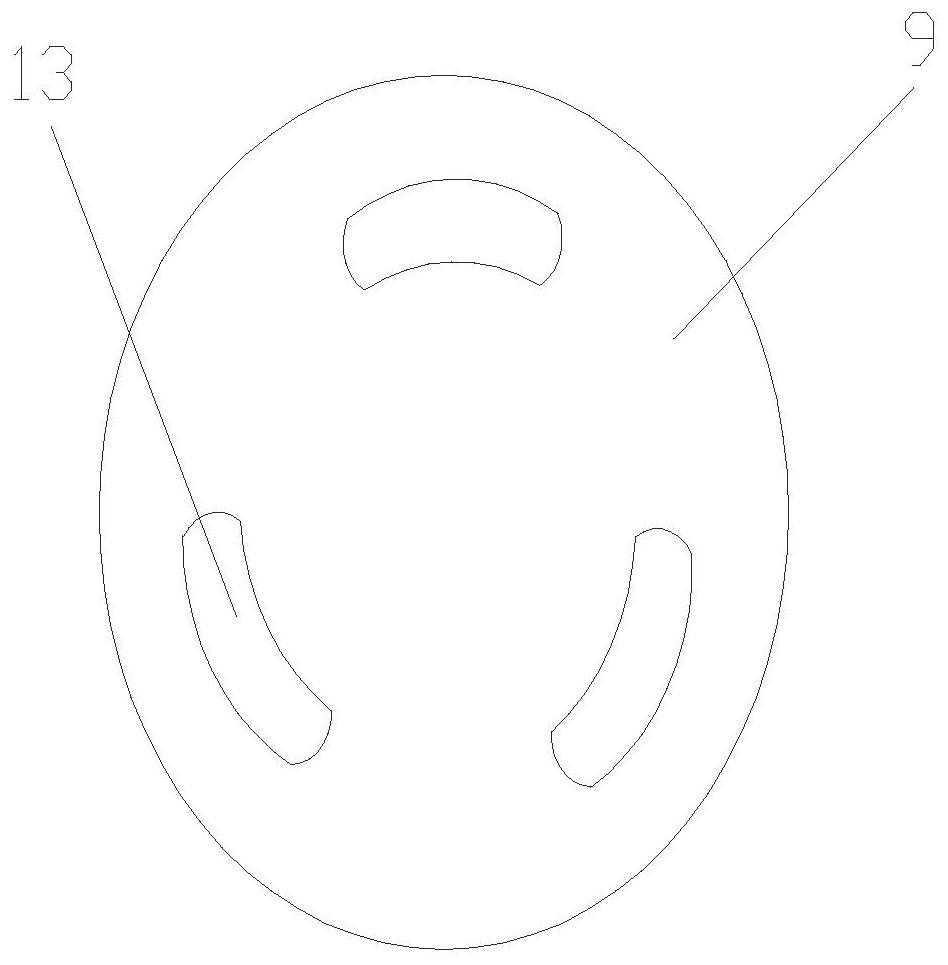

[0018] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the front valve disc in the present invention, image 3 It is a structural schematic diagram of the driven disc in the present invention, Figure 4 It is a structural schematic diagram of the composite bearing in the present invention. As shown in the figure, the drill bit with circumferential rotational force in this embodiment includes a drill body and a drill seat assembly connected between the drill rod and the drill body and used to generate circumferential rotational force; The drill head assembly includes a fixedly connected rear connecting pipe 1, a middle pipe body 2, and a front connecting pipe 3 from back to front. The middle pipe body is sequentially provided with an impact assembly and The impact assembly drives the matching power assembly; the power assembly is a hydraulic power assembly; a disc valve assembly is also arranged between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com